PVC Waterproof Membrane in 1.5mm Thickness and Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproof Membrane in 1.5mm Thickness

Product Description of PVC Waterproof Membrane in 1.5mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproof Membrane in 1.5mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Waterproof Membrane in 1.5mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproof Membrane in 1.5mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane in 1.5mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane in 1.5mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

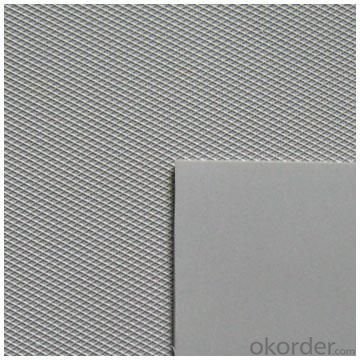

Images of PVC Waterproof Membrane in 1.5mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in areas with vehicular traffic?

- Certainly! It is indeed possible to utilize a waterproofing membrane in regions frequented by vehicles. In reality, there exist distinct variants of waterproofing membranes meticulously crafted to endure the pressure and motion exerted by automobiles. These specialized membranes, referred to as vehicular or traffic-bearing membranes, are generally composed of sturdier materials like rubberized asphalt or modified bitumen. They are purposefully engineered to furnish a robust and flexible barricade against water and moisture, whilst simultaneously withstanding the burdensome loads and incessant traffic commonly associated with vehicles. Vehicular membranes find widespread application in parking garages, bridges, and other sites where vehicles are commonly found.

- Q: Can a waterproofing membrane be used on plywood?

- Yes, a waterproofing membrane can be used on plywood. Plywood is a commonly used material for construction and can be susceptible to water damage. Applying a waterproofing membrane on plywood helps to protect it from water infiltration and can improve its durability and longevity.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Yes, waterproofing membranes can indeed be used on rooftop terraces. In fact, they are often utilized to protect the structural integrity of the terrace and prevent water damage to the underlying structure. Rooftop terraces are exposed to various weather conditions, including rain, snow, and UV rays, which can lead to leaks and deterioration. Waterproofing membranes act as a barrier, preventing water from seeping through the surface and causing damage. These membranes are specifically designed for outdoor use and can withstand the harsh conditions typically found on rooftops. They are available in various materials such as modified bitumen, EPDM (ethylene propylene diene terpolymer), and PVC (polyvinyl chloride), allowing for flexibility in choosing the most suitable option for a specific terrace. Additionally, waterproofing membranes can be installed under various types of terrace finishes, including pavers, tiles, and decking, providing a versatile solution for different design preferences. Overall, the use of waterproofing membranes is highly recommended for rooftop terraces to ensure their longevity, durability, and resistance to water-related issues.

- Q: Can a waterproofing membrane be used on terracotta surfaces?

- Terracotta surfaces can benefit from the use of a waterproofing membrane. Due to its porous nature, terracotta absorbs water and can suffer damage and deterioration as a result. To prevent such issues, applying a waterproofing membrane creates a barrier that stops water from penetrating and safeguards the material against moisture-related problems. Acting as a protective layer, the membrane keeps the terracotta surface dry and prevents water from seeping through. This is especially advantageous in areas with high moisture levels or where terracotta is exposed to water, like bathrooms, kitchens, or outdoor installations. To ensure compatibility and effectiveness, it is crucial to select a waterproofing membrane specifically designed for terracotta surfaces. Additionally, following proper surface preparation and application techniques is essential for achieving optimal results.

- Q: What is the cost of installing a waterproofing membrane?

- The installation expense of a waterproofing membrane can fluctuate based on several factors, including the dimensions of the area to be waterproofed, the type of membrane employed, and the intricacy of the installation procedure. Typically, the cost per square foot can vary between $3 and $10. Nevertheless, it is crucial to bear in mind that this is merely a ballpark figure, and the real cost may be higher or lower depending on the particular demands of the project. It is advisable to seek guidance from an expert waterproofing contractor to obtain a precise cost estimate customized to your specific requirements.

- Q: Can waterproofing membranes be used on mechanical rooms?

- Indeed, mechanical rooms can benefit from the application of waterproofing membranes. Within these rooms, one can frequently find water-sensitive equipment like boilers, pumps, and ventilation systems. By installing waterproofing membranes, it is possible to establish a safeguarding shield against water infiltration, thus averting any leaks, moisture accumulation, or potential harm to the equipment. Moreover, these membranes also possess the ability to offer thermal insulation, noise reduction, and fire resistance attributes. Therefore, it becomes crucial to select the suitable waterproofing membrane type that aligns with the distinct necessities and prerequisites of the mechanical room.

- Q: Construction Measures for Waterproof Coil in Winter

- 3. Do the seam and the end of the handle. In order to improve the reliability of the winter construction, to prevent the waterproof layer after the hot-melt paving seam with the possibility of seaming, requiring the mouth and the end of the mouth are sealed with sealing material to improve the waterproof impermeability.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Yes, a waterproofing membrane can certainly be used in stadiums or sports complexes. In fact, it is highly recommended to use waterproofing solutions in these types of structures to protect them from water damage and leakage. A waterproofing membrane acts as a barrier, preventing water from seeping into the concrete or other materials used in the construction of the stadium or sports complex. This is particularly important in areas where heavy rainfall or high humidity is common. By applying a waterproofing membrane to the roofs, walls, and foundations of these structures, it helps to ensure the integrity and longevity of the building, while also providing a comfortable and safe environment for athletes and spectators alike. Waterproofing membranes are designed to withstand the stresses and movements associated with the building, making them an ideal solution for stadiums and sports complexes. Additionally, modern waterproofing membranes are available in various forms, such as liquid-applied or sheet membranes, allowing for flexibility in application and compatibility with different construction materials.

- Q: Are waterproofing membranes resistant to algae growth?

- Yes, waterproofing membranes are typically resistant to algae growth. The materials used in these membranes are often designed to be non-porous and inhibit the growth of algae and other organic matter. Additionally, some membranes may have additional features such as UV resistance or anti-microbial properties that further deter algae growth.

- Q: Can waterproofing membranes be used on concrete reservoirs?

- Concrete reservoirs can indeed benefit from the use of waterproofing membranes. These membranes have been specially designed to shield against moisture and water infiltration, making them an excellent choice for concrete reservoirs that require a reliable watertight solution. Typically, these membranes are applied directly to the concrete surface, creating a seamless and long-lasting waterproof layer. Their effectiveness in preventing water leakage, seepage, and dampness ensures the structural integrity and longevity of the concrete reservoir. Furthermore, these waterproofing membranes offer resistance against chemicals, UV rays, and other environmental factors, thus further enhancing the durability and performance of the concrete reservoir. It is crucial to select a high-quality waterproofing membrane specifically designed for concrete structures and to adhere to the manufacturer's instructions regarding proper application and maintenance.

Send your message to us

PVC Waterproof Membrane in 1.5mm Thickness and Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords