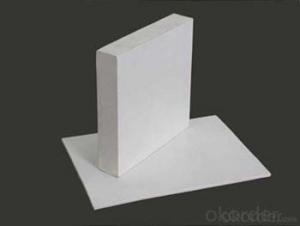

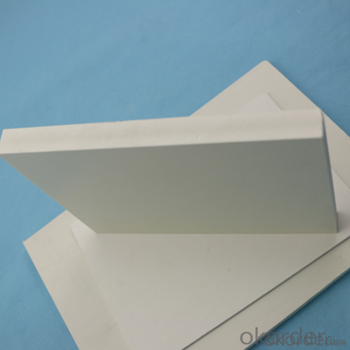

Plastic Sheets - PVC Sheet White 5mm Thickness, Hardness ≥10MPa

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

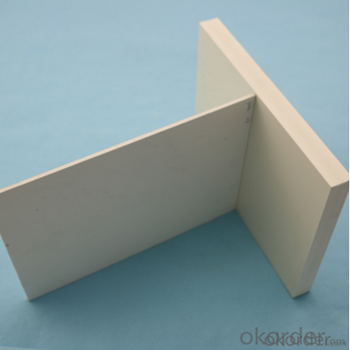

Specification

About us:

We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer.

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Features:

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

The Advantages:

Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places. The global spread of overseas warehouse for our shipment to the nearest

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Q: How to get the price?

A: Please tell me the following information and I'll send you the quotation without delay:

color (white,black,grey,red,blue or other)

thickness (1mm~30mm)

size (1220x2440mm standard,customized is available)

density (0.35-0.80)

quantity(affecting the delivery time

Low Price Excellent chemical and corrosion resistance 3mm pvc foam board.

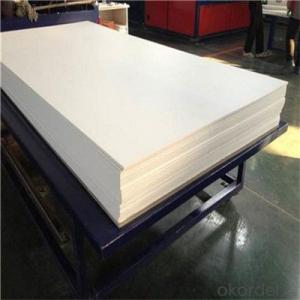

Product pictures

Packing picture

- Q: Can plastic sheets be used for decorative purposes?

- Yes, plastic sheets can be used for decorative purposes. They can be molded into various shapes and designs, allowing for creative and unique decorations. Additionally, plastic sheets come in a wide range of colors and finishes, making them versatile for different decorative applications.

- Q: I must be an idiot. I bought GBC's SelfSeal Laminating Sheets (9x12) and need to laminate both sides of a 8.5x11 piece of paper. The instructions say to lay the paper face down on the non adhesive side and then peel away the liner and seal. What am I supposed to seal it with? Another laminating sheet? When I pull the liner away the adhesive side is facing away from the page and sticks to everything. Any help would be appreciated.Thanks

- If it is laminating sheets, just one sheet of plastic adhesive, then yes, you need to use two and sandwich the paper in between. What I do is lay the laminating sheet with the liner facing up. I peel off the liner and center my paper on the adhesive. Then I take just the end of the liner off another sheet and place it very carefully lined up with the first one, adhesive side down. Then I carefully pull the liner off as I smooth the top laminating sheet over the paper. You have to do it very carefully to avoid wrinkles. Then you can cut off the excess right around the edge of your page if you want to; it is very hard to position the sheets without a little bit of overhang with adhesive exposed. NOW, if it is a laminating pouch, that is a totally different thing. You have to place your paper in between the two sheets of plastic that make up the pouch and peel the liner paper off the side that has liner paper, and smooth it over your page. But I am pretty sure you are just talking about laminating sheets like I described in the first paragraph. Hope this helps!

- Q: Are plastic sheets resistant to humidity?

- Yes, plastic sheets are generally resistant to humidity.

- Q: PVC how dirty is the plastic board? Can it be cleaned soon?

- Wet the cloth with a dusterFind a relatively soft cloth at home and then wet again from top to bottom to scrub again, this will not cause damage to the plastic plate, cleaning can be assured, if you have time to periodic cleaning.

- Q: Where can I purchase Nuetural or white ABS plastic rods, sheets, pipes, or pellets?

- www.okorder / Our payment method:Western Union Transfer The Wholesale( nike adidas puma bape timberland ice cream prada gucci)Best priceList : 38 euro per pair for 6 pairs of all nike shoes 36 euro per pair for 12 pairs of all nike shoes 35 euro per pair for 24 pairs of all nike shoes

- Q: those plastic sheets that can be usd in picture frames, on the shed or in the house, I have seen them in BQ, what shall i type when searching for the plastic sheet on 'OKorder', I have typed plastic sheets but no luck, can you help me on this one.

- For a rigid sheet they're typically polymethylmethacrylate (PMMA) or the trade name Lexan. PMMA is cheaper than polycarbonate.

- Q: Lets say person A buys 2 tabs of acid, puts it in a plastic baggy, and inserts in pocket. Is there any chance of the lsd bleeding through the plastic and being absorbed into person A's leg?

- No, there is far too little LSD to be absorbed. Plus plastic barrier will act as a barrier.

- Q: Can plastic sheets be used for point-of-purchase displays?

- Yes, plastic sheets can be used for point-of-purchase displays. Plastic sheets are a versatile material that can be easily shaped, printed on, and customized to create eye-catching displays for products in retail environments. They offer durability, transparency, and flexibility, making them an ideal choice for showcasing merchandise and attracting customers at the point of purchase.

- Q: How durable are plastic sheets?

- Plastic sheets are generally durable and can withstand various environmental factors, such as moisture, UV radiation, and temperature fluctuations. However, the durability of plastic sheets can vary depending on the specific type of plastic, thickness, and intended use. Some plastics are designed to be more impact-resistant or resistant to chemical exposure, while others may be more prone to scratching or discoloration over time. Therefore, it is important to consider the specific application and quality of the plastic sheet when assessing its durability.

- Q: Are plastic sheets resistant to moisture condensation?

- Yes, plastic sheets are generally resistant to moisture condensation due to their non-porous nature.

Send your message to us

Plastic Sheets - PVC Sheet White 5mm Thickness, Hardness ≥10MPa

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords