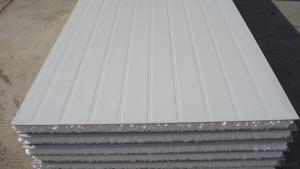

Plastic Sheets - 2024 High Density White PVC Foam Sheet 3mm Thick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam is a special form of PVC, but the base material is still manufactured using the same process used to create all PVC products. PVC falls into the category of thermoplastic resins. It is made primarily from a combination of chlorine and carbon. The carbon in the plastic is obtained from oil and gas, but this plastic actually requires less oil and gas than many other types of plastic products.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Production Capacity:10000pcs per month

Usage Life: more than 50 years

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1). exhibition desk, Shelve in supermarket

(2). Advertisemen Board and sign board

(3). the advertisement sheet for printing,engraving,cutting,sawing

(4). Architectural decoration and upholstery

(5). decoration for partition wall and shopwindows

5.Product Pictures

- Q: How do plastic sheets handle extreme weather conditions?

- Plastic sheets are designed to be resistant to various weather conditions, including extreme ones. They can withstand high temperatures, heavy rain, strong winds, and even freezing temperatures. Their durable and flexible nature allows them to expand and contract without cracking or warping, making them suitable for use in extreme weather conditions. Additionally, some plastic sheets are UV-stabilized, which means they can resist the damaging effects of prolonged sun exposure. Overall, plastic sheets are highly resilient and can effectively handle extreme weather conditions.

- Q: Are plastic sheets resistant to cracking or splitting?

- Yes, plastic sheets are generally resistant to cracking or splitting due to their flexibility and durability.

- Q: How do plastic sheets compare to HDPE sheets?

- Plastic sheets and HDPE sheets are essentially the same thing. HDPE stands for High Density Polyethylene, which is a type of plastic. So, plastic sheets and HDPE sheets are made of the same material, but HDPE sheets have a higher density and are generally more durable and resistant to impact, chemicals, and weathering compared to other plastic sheets.

- Q: Can plastic sheets be used for visual displays?

- Yes, plastic sheets can be used for visual displays. They are often used in various industries and applications such as advertising, retail displays, signage, and exhibitions due to their versatility, durability, and ability to be easily shaped into different forms. Additionally, plastic sheets can be transparent, colored, or have various finishes to enhance the visual appeal of the display.

- Q: I need a cheap coin case for my morgan silver dollars would plastic card sheets which are like plastic sheets with card slots in them hold coins good and then i could make a book out of them which would be pretty cool. if you guys dont think this will work tell me some good coin holders.

- Not for loose coins. The coins need to be in cardboard/Mylar 2x2 'flip' holders. Those will fit into 9-pocket sheets, although not tightly. Better is to buy plastic 20-pocket sheets the same places you buy the flips. They're not much more expensive than card sheets.

- Q: what is the overlayer plastic sheet used on standard dvd and game case called?

- it particularly is thoroughly pointless, i think of human beings could basically have the skill to purchase movies of On call for or Verizon and function the skill to maintain them continually on like a stored folder, and then with comparable track on Itunes and automobiles could come put in with iPod holders so which you will play that quite of CD's, haha I easily have extraordinary philosophy.

- Q: They use them a lot in Japan, but I can't remember what they are called (in Japanese) and I have no idea what you would call them in English. They are just a clear coloured piece of plastic that you slide under your notebook page as you write to stop indents from your pen going onto the next page. Does anyone know what these would be called??

- I have only heard them called page protectors. Hopes this helps.

- Q: Titanium sheet, lets say thickness 250 microns (0,010''), and size 3.5 x 2.5. How far could it bend so when you release it it goes back to its original shape (without any shape change or damage)? Could it act same as/close to a (plastic) playing card? Shuffle, bend half of the card when you are looking at it while its laying on the table?

- In alloyed condition it’s as strong as steel but 45% lighter and also ductile Under mentioned conditions, it will not behave as you mentioned

- Q: I have to do environmental poster for a class and wanted to know how thick the sheet of plastic is.

- I'm not aware of any sheet of plastic at the bottom of the ocean.

- Q: What are the most common applications for plastic sheets?

- Plastic sheets are commonly used in various applications such as packaging, signage, construction, automotive, and medical industries. They are also used for manufacturing products like windows, doors, protective barriers, display cases, and various household items.

Send your message to us

Plastic Sheets - 2024 High Density White PVC Foam Sheet 3mm Thick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords