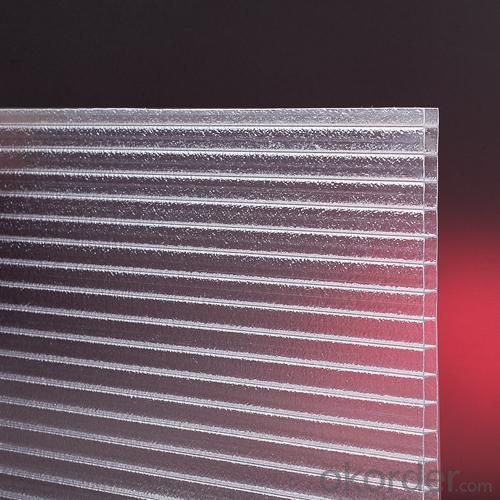

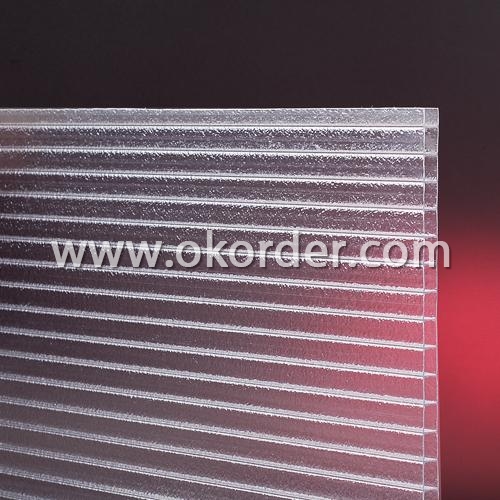

Plastic Sheets - 10 Year Quality Frosted Polycarbonate Sheet in Many Colors

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000KG kg

- Supply Capability:

- 3000,000KG Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of 10 Year Quality Frosted Polycarbonate Sheet With Many Colors

1 100% virgin Bayer material

2 Size : Length : 5800mm,11800mm ; Maximun width : 2100mm ; size can as customer requirement

3 Thickness: 4mm-10 mm

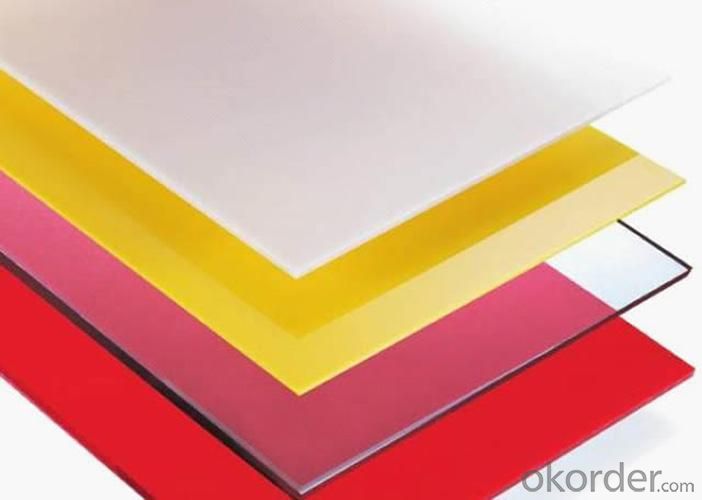

4 Color: clear, green, blue , light blue , brown , opal , red , yellow and so on.

5 UV protection(One side or two sides)

6 Warranty time:10 year

7 Payment : T/T , LC

8 Package: Double sides are with PE films

9 Delivery time:25-30 days for 1*40FCL

Features of 10 Year Quality Frosted Polycarbonate Sheet With Many Colors

1 Light weight

2 Very high impact strength

3 Good light transmission

4 High heat insulation

5 Simply processed and installed

6 UV protection layer: 50um

Applications of 10 Year Quality Frosted Polycarbonate Sheet With Many Colors

1 Roofing light sheet and sunshade for office building, department store, hotel, stadium, school, amusement center, hospital, ect.

2 Do-It-Yourself (DIY), awning, canopy.

3 Anti-riot shield, bullet resistant material, Bank ATMs.

4 Conservatories, agricultural greenhouses, zoos, botanical gardens.

5 Industrial Roofing and Glazing

6 Swimming Pools roofing/cover/sheet

Pictures of 10 Year Quality Frosted Polycarbonate Sheet With Many Colors

- Q: what is shrinkage for pp+15%epdm plastic can i have the data sheet?

- You can sign in and get the data sheet at the link below.:

- Q: Can plastic sheets be used for picture framing?

- Yes, plastic sheets can be used for picture framing. They are often used as an alternative to glass due to their lightweight, shatterproof, and UV-resistant properties. Plastic sheets such as acrylic or polycarbonate provide protection for artwork or photographs while still allowing clear visibility.

- Q: How long do plastic sheets last?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic, its quality, usage conditions, and maintenance. Generally, high-quality plastic sheets can last for several years or even decades if properly cared for and not exposed to harsh conditions.

- Q: Where can I buy thin plastic sheets or on a roll. It needs to be about the thickness of the plastic on a milk jug or a little thinner. Any ideas?

- at a major lumber store, look for 6 mil comes in 10 foot by 50 foot rolls

- Q: Can plastic sheets be used for signs and banners?

- Yes, plastic sheets can be used for signs and banners. They are durable, weather-resistant, and can be easily printed on or have vinyl lettering applied.

- Q: It looks like a plastic, but I know there is a specific name for it.And maybe if you know the name, what big brand stores sell them?thank you soooo much for any help!

- Photo gels, and none. They're a specialty item

- Q: Are plastic sheets scratch resistant?

- Yes, plastic sheets can be scratch resistant. However, the level of scratch resistance may vary depending on the type of plastic used and the specific manufacturing process.

- Q: Are plastic sheets suitable for electrical enclosures?

- Yes, plastic sheets can be suitable for electrical enclosures as they offer insulation, corrosion resistance, and are cost-effective compared to other materials like metal. However, the specific requirements and safety standards for the electrical enclosure should be considered to ensure the plastic sheets meet the necessary criteria for the intended application.

- Q: What is the minimum temperature that plastic sheets can withstand?

- The minimum temperature that plastic sheets can withstand varies depending on the type of plastic. However, most common plastic materials can typically withstand temperatures as low as -40°C to -60°C.

- Q: How are plastic sheets different from other materials like glass or metal?

- Plastic sheets differ from materials like glass or metal primarily due to their composition and properties. Unlike glass, which is made from silica and metal, which is derived from various elements, plastic sheets are made from synthetic polymers derived from petroleum or natural gas. This difference in composition gives plastic sheets their unique characteristics such as flexibility, lightness, and resistance to impacts and weathering. Plastic sheets are also more cost-effective to produce and easier to shape and mold compared to glass or metal, making them widely used in various industries.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 20.00% Mid East 15.00% Northern Europe 15.00% North America 12.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 4.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Plastic Sheets - 10 Year Quality Frosted Polycarbonate Sheet in Many Colors

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000KG kg

- Supply Capability:

- 3000,000KG Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords