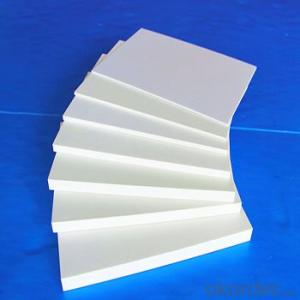

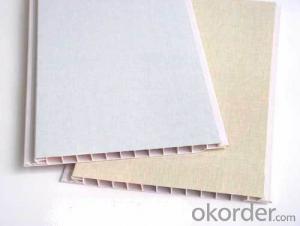

Light Weight PVC Foam Board PVC Celuka Board Plastic Forex Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3. Features

1) UVprotected, Antichemical corrosion

2) Fire retardant and it can automatically extinguish by itself

3) Sound insulation, sound absorption, heat insulation and heat preservation

4) Moistureresistant, mildew proof, water repellent and shock proof

5) Nondeformation, agingresistant, color fastness for a very long time through particular formula

6) Light weight, easy and convenient for storage, transportation and using

7) It has a smooth and hard surface and is suitable for painting

4. Pictures

- Q: What I want to build is a cube made out of semi-transparent acrylic sheets with a lightbulb ballast screwed down to the floor of the cube and the electrical cord leading out. This will look really cool because it will be a soft white light cube that can be used even as a side table. I don't know where to get the acrylic sheets or how to attach them to each other. I imagine using epoxy, but if anyone has better ideas please provide them. Thanks!

- Home Depot and Lowe's has this they are used for florescent light covers that are recessed in the ceiling. You will also ned the special type of glue for this type of plastic.

- Q: Can plastic sheets be used for DIY lampshades?

- Yes, plastic sheets can be used for DIY lampshades. They are a versatile material that can be easily cut and molded into various shapes and sizes. However, it's important to choose the right type of plastic sheet that is heat-resistant and suitable for lampshade usage.

- Q: How do plastic sheets compare to ABS sheets?

- Plastic sheets and ABS sheets have distinct properties and uses. ABS (Acrylonitrile Butadiene Styrene) sheets are a specific type of plastic sheet known for their excellent impact resistance and durability. They are commonly used in automotive parts, electronics, and toys due to their strength and ability to withstand heavy-duty applications. On the other hand, plastic sheets encompass a broader category and can include various materials such as acrylic, polycarbonate, and polyethylene. Each type of plastic sheet has its own unique characteristics and applications. While ABS sheets excel in impact resistance, other plastic sheets might offer superior optical clarity, chemical resistance, or flexibility. Ultimately, the choice between plastic sheets and ABS sheets depends on the specific requirements of the project or application at hand.

- Q: Are plastic sheets resistant to bending during transportation?

- Yes, plastic sheets are generally resistant to bending during transportation due to their flexible and durable nature. However, the specific resistance to bending may vary depending on the thickness and type of plastic used.

- Q: I've been working with a lot of humanitarian help lately, and have noticed that most mediocre plastic sheeting (tarpaulin) is blue whereas the good stuff is white or white on one side and black on the other. Why is most plastic sheeting blue? Is there any particular reason for this choice in color?

- 1) Blue is a color that contrasts most other natural colors in it's surroundings such as green grass and brown dirt, and therefore is found easily for cleanup. 2) Out of the colors they could use, blue is the cheapest to produce. Black, and surprisingly even white, costs more than blue die. This is because most raw plastic is a gray or multiple colors, so it takes more bleach to make it white than it does to just color it blue. Plus the materials necessary to create blue die are cheaper than most other colors. 3) Blue does not absorb as much heat as some other colors would, and therefore will keep it's integrity longer.

- Q: What is aluminum plastic sheet?

- The aluminum plastic composite plate is a composite material made of chemically treated coated aluminium plate as surface material, polyethylene plastic as core material, and manufactured on special aluminum plate production equipment.

- Q: my car windscreen sticker was full of permanent marker marks done by little kids. i need to lift the marks without spoiling the sticker.

- I am afraid that you may end up to get new sticker. Usually permanent markers can be erased by Acetone, Clorox, or such. However all these chemicals may damage the sticker.

- Q: Can plastic sheets be used for interior design purposes?

- Yes, plastic sheets can be used for interior design purposes. They are versatile and available in various textures, colors, and patterns, making them suitable for applications such as wall coverings, room dividers, furniture accents, or even lighting fixtures. Additionally, plastic sheets are often more affordable and easier to install or maintain compared to other materials, offering designers a wide range of creative possibilities for interior design projects.

- Q: Are plastic sheets resistant to yellowing over time?

- Yes, plastic sheets can be resistant to yellowing over time depending on the type of plastic used. Some plastics, such as acrylic and polycarbonate, have excellent resistance to yellowing and can maintain their clarity for extended periods. However, other types of plastics may be more prone to yellowing due to exposure to UV light, heat, or certain chemicals. It is important to choose the right type of plastic sheeting for specific applications to ensure long-term clarity.

- Q: What are the different types of plastic sheets available?

- There are numerous types of plastic sheets available, including acrylic, polycarbonate, PVC, ABS, HDPE, and LDPE. Each type has unique properties and characteristics that make them suitable for various applications such as signage, packaging, construction, and fabrication.

Send your message to us

Light Weight PVC Foam Board PVC Celuka Board Plastic Forex Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords