PVC Electrical Tape 110-200 Micron Waterproof Shape Tape Packaging SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

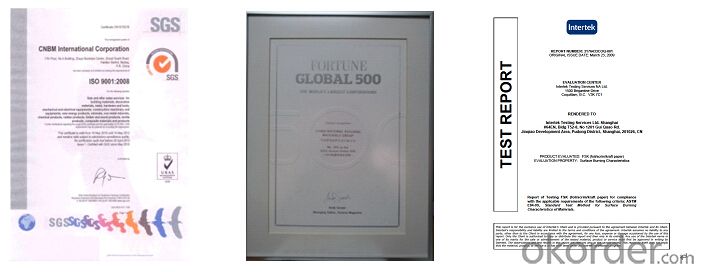

• World Top 500 Enterprises

• Resistance to cold, heat and aging

• Best quality and competitive price

• SGS&ISO9001, Customs Grade AA

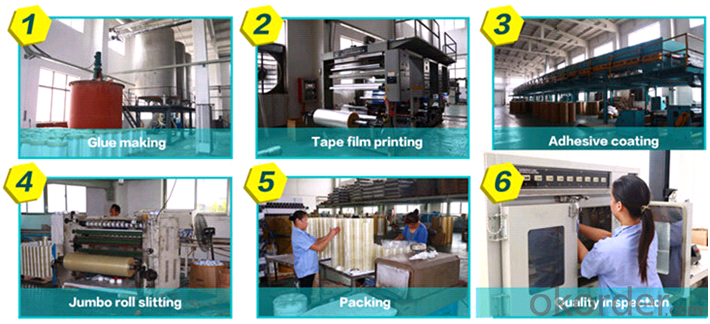

The PVC Electrical Tape is of PVC film as the carrier, coating with rubber based adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to electrical products.

The thickness of the tape can be customized.

PVC Electrical Tape is ideal for insulating, protection and color coding of electrical wires; may also be used as harness tape in automotive industry.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

| Standard size | 19mm*10m, 19mm*20m, 1.25m*10m, 1.25m*33m, etc |

| Thickness (micron) | 110 |

| Color | All Color Available |

| Adhesion to steel (N/cm) | 1.5 |

| Tensile Strength (N/cm) | 18 |

| Elongation at break (%) | 190 |

| Dielectric breakdown (V) | 600 |

| Flame Resistance (s) | <5 |

| Packing | Carton |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

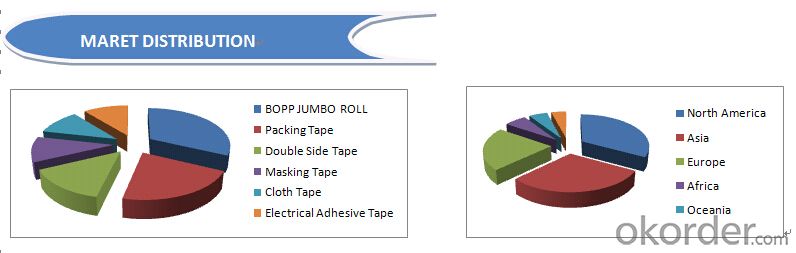

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

You are welcome to contact me at any time and visit the factory in China!

- Q: 2014, how can I sell the tape better?

- Fourth, the background of your company must say company influence and company history,Fifth, the market prospects and profit margins, regardless of the price of your products is how much of that is not a problem, and if you have a small list of hands, you can put the list to be introduced to customers, these are my experience to sell, can only give you a reference, are different for each personal selling, to try to know,

- Q: Can packaging tape be used for sealing plastic storage jars?

- Indeed, packaging tape proves to be a versatile tool for sealing plastic storage jars. Crafted to offer a robust and dependable seal, packaging tape is apt for diverse applications, including the sealing of plastic storage jars. By utilizing it, one can effectively safeguard the contents of the jar, ensuring no leaks or contamination occur. Nevertheless, it is important to acknowledge the existence of alternative options specifically tailored for jar sealing, such as jar lids and seals. These alternatives may offer an even more secure and hermetic seal.

- Q: Does packaging tape come in different patterns or designs?

- Yes, packaging tape does come in different patterns and designs. While traditional packaging tape is usually plain and transparent, there are also various options available for those who want to add a touch of creativity or personalization to their packages. Some common patterns and designs include bold colors, stripes, polka dots, floral prints, geometric designs, and even custom logos or messages. These decorative tapes can be a fun and unique way to enhance the appearance of your packages and make them stand out. Furthermore, some packaging tape brands offer seasonal or themed designs, allowing you to match your packaging tape to specific occasions or holidays.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Indeed, when it comes to sealing packages with irregular shapes, packaging tape comes in handy. Its flexibility and adhesive nature make it perfect for securing packages of different sizes and contours. Thanks to its strong adhesive properties, packaging tape can adhere to various surfaces, even those that are uneven or irregular, ensuring that the package remains tightly sealed during transportation. Moreover, packaging tape is known for its durability and tear-resistance, providing an added layer of protection for the package. Consequently, whether the package boasts an irregular shape or not, packaging tape proves to be a dependable and efficient choice for sealing it securely.

- Q: Can packaging tape be used for other purposes?

- Yes, packaging tape can certainly be used for other purposes beyond its primary use of sealing packages. Due to its strong adhesive properties and durability, it can be used for various other applications. One common alternative use of packaging tape is for organizing and bundling items together. Whether it's sorting cables and cords, securing loose items, or grouping similar items, packaging tape can effectively keep things neatly organized. It can also be used to secure items to walls or surfaces temporarily, such as posters or decorations, without causing any damage. Additionally, packaging tape can be utilized for crafting and DIY projects. Its adhesive nature makes it a great material for creating temporary or permanent bonds between different materials. It can be used to repair torn papers, create labels or tabs, or even make custom stickers. Its versatility and availability in different widths and lengths make it a handy tool for various creative endeavors. Moreover, packaging tape can be utilized for household fixes and repairs. From mending broken items to reinforcing weak joints, the strong adhesive properties of packaging tape can provide a quick and temporary solution. It can also be used to seal minor leaks or cracks temporarily until a proper repair can be made. In conclusion, while packaging tape is primarily designed for sealing packages, its strong adhesive properties and versatility make it suitable for various other purposes. Whether it's organizing, crafting, or quick fixes, packaging tape can be a useful tool to have on hand.

- Q: How do I apply packaging tape evenly?

- To apply packaging tape evenly, follow these steps: 1. Start by ensuring that the surface you are taping is clean and free of any dust, dirt, or moisture. This will help the tape adhere properly. 2. Measure the length of tape you need and cut it accordingly. It is better to have a slightly longer piece of tape than a shorter one. 3. Hold one end of the tape firmly against the surface you are taping and apply it at a slight angle, using gentle pressure. This will help prevent air bubbles and ensure a smooth application. 4. As you continue applying the tape, make sure to keep it taut and straight. Avoid stretching or pulling the tape too tightly, as this can cause it to lose its adhesive properties. 5. Use your fingers or a tape dispenser to press down on the tape firmly, smoothing it out as you go. This will help ensure that it adheres properly and evenly to the surface. 6. If you encounter any wrinkles or bubbles while applying the tape, gently lift the tape and reapply it, smoothing it out as you go. 7. Repeat the process until you have covered the desired area with the tape, making sure to overlap the edges slightly for a secure seal. By following these steps, you should be able to apply packaging tape evenly, creating a neat and secure seal for your packages.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. Packaging tape is designed to have strong adhesive properties, making it ideal for securing and sealing various items, including sports equipment. It can help keep equipment and gear securely fastened, preventing them from coming apart or getting damaged during transportation or storage. However, it's important to consider the specific needs and requirements of the sports equipment or gear being sealed, as some items may require more specialized tapes or sealing methods for optimal protection.

- Q: Is packaging tape resistant to punctures or tears?

- Yes, packaging tape is generally resistant to punctures or tears. It is designed to be strong and durable, specifically for securing and sealing packages. Packaging tape is made from materials such as polypropylene or polyester, which have high tensile strength and offer excellent resistance to punctures or tears. Additionally, packaging tape often has adhesive properties that further enhance its ability to withstand punctures or tears. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: Is packaging tape resistant to UV rays?

- Yes, packaging tape is typically designed to be resistant to UV rays.

Send your message to us

PVC Electrical Tape 110-200 Micron Waterproof Shape Tape Packaging SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords