Custom Packaging Tape Melbourne - BOPP Adhesive Bag Sealing Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

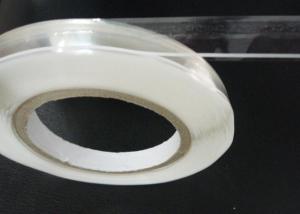

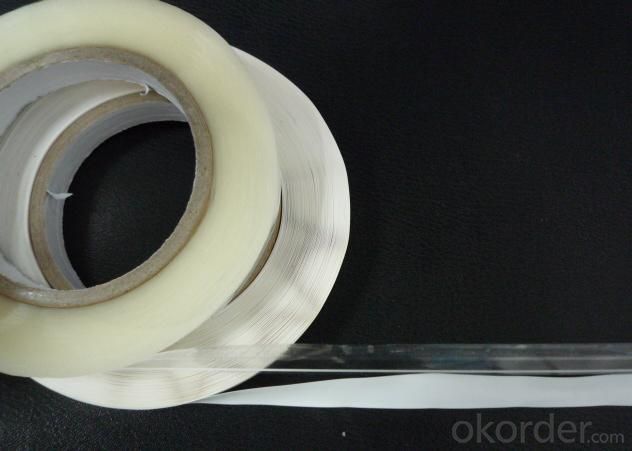

General Information Of bopp adhesive bag sealing tape

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Item No BG-14

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/6mm (left/right glue)

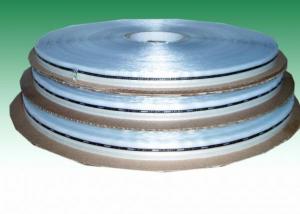

Packing Of bopp adhesive bag sealing tape

Core I.D.: 3” (76mm?1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

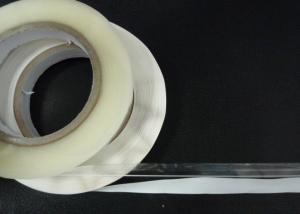

Application Of bopp adhesive bag sealing tape

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

Service Of bopp adhesive bag sealing tape

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

Handing and Storage Of bopp adhesive bag sealing tape

Handling procedures:Caution with edge of sheet. After using this sheet, wash hands.

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Stability and Reactivity Of bopp adhesive bag sealing tape

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

Transport Information Of bopp adhesive bag sealing tape

Not a hazardous material for DOT shipping.

UN:None

Packaging sign:According to the buyer

Packaging Category:No information found/According to the buyer.

Shipping Marks: According to the buyer

Remarks Of bopp adhesive bag sealing tape

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: 10%; Width: 3mm; Length: Cut Roll & Log Roll 0.3m, Jumbo Roll 0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, make sure to apply it smoothly and evenly, without any folds or creases. Start by holding the tape at a slight angle and pressing it firmly onto the surface, while gradually unrolling it. Avoid tugging on the tape too forcefully, as this can cause it to wrinkle. Additionally, using a good quality tape dispenser or a handheld tape gun can help ensure a smooth application.

- Q: Can packaging tape be used for sealing cloth or fabric items?

- Packaging tape has the capability of sealing cloth or fabric items. Its design ensures strength and adhesive properties, making it efficient for securing and sealing different materials, such as cloth and fabric. When it comes to packages containing cloth or fabric items, packaging tape becomes particularly handy as it ensures a secure closure that prevents any potential damage or loss during transportation or storage. Furthermore, the transparency of packaging tape allows for effortless identification of the contents while maintaining the overall appearance of the cloth or fabric item intact.

- Q: Can packaging tape be used for sealing electronic devices?

- Packaging tape should not be used for sealing electronic devices. While packaging tape is commonly used for securing boxes and packages, it is not designed for sealing electronic devices. Electronic devices require specific types of sealing materials to ensure proper protection against moisture, dust, and other environmental factors. Using packaging tape can lead to inadequate protection, potentially exposing the electronic device to damage or malfunction. It is advisable to use appropriate sealing methods and materials recommended by the manufacturer or seek professional assistance when sealing electronic devices.

- Q: Does packaging tape come in different odor-free options?

- Yes, packaging tape does come in different odor-free options. Many manufacturers offer packaging tape that is specifically designed to be odorless, making it ideal for sensitive individuals or products that may be affected by strong scents.

- Q: How do I prevent packaging tape from yellowing over time?

- To prevent packaging tape from yellowing over time, it is essential to store it in a cool, dry, and dark place. Exposure to sunlight and humidity can accelerate the yellowing process. Additionally, using high-quality packaging tape made from materials resistant to discoloration can help maintain its original appearance for a longer period.

- Q: What is the best way to apply packaging tape?

- The best way to apply packaging tape is to first ensure that the surface is clean and dry. Start by holding the tape dispenser at a slight angle and pressing firmly on the surface, moving the dispenser smoothly in a straight line. Avoid stretching or folding the tape as it can weaken its adhesive properties. Finally, use a sharp object to cut the tape cleanly, ensuring a secure and professional seal.

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q: What is the profit margin of the transparent tape for packaging?

- Now, many of the tapes are closed and the profits are too transparent

- Q: Can packaging tape be used for sealing wooden crates?

- Sealing wooden crates can indeed be accomplished with packaging tape, which creates a sturdy and reliable bond. This ensures that the crate remains tightly sealed throughout transportation or storage. Packaging tape is specifically designed to adhere well to different surfaces, including wood, making it an excellent option for sealing wooden crates. Nevertheless, it's crucial to take into account the weight and dimensions of the crate before solely depending on packaging tape. In the case of heavier or larger crates, reinforcing the seal with supplementary methods like nails or screws may be necessary.

- Q: Can packaging tape be used for sealing medical or laboratory containers?

- Packaging tape is not recommended for sealing medical or laboratory containers. While packaging tape may provide a temporary seal for general packaging purposes, it is not designed or tested to meet the specific requirements of medical or laboratory environments. Medical and laboratory containers often require specialized sealing methods to ensure airtight and sterile conditions, as well as to prevent contamination or tampering. These containers typically use specialized seals, such as adhesive strips, rubber gaskets, or screw caps, that are specifically designed to meet the stringent requirements of medical or laboratory applications. Therefore, it is crucial to use the appropriate sealing methods and materials recommended by the manufacturer or industry standards to ensure the integrity and safety of medical or laboratory containers.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | produce single sided tapes,double sided tapes, masking tape, Opp tape |

| Product Price Range | High; Average |

Send your message to us

Custom Packaging Tape Melbourne - BOPP Adhesive Bag Sealing Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords