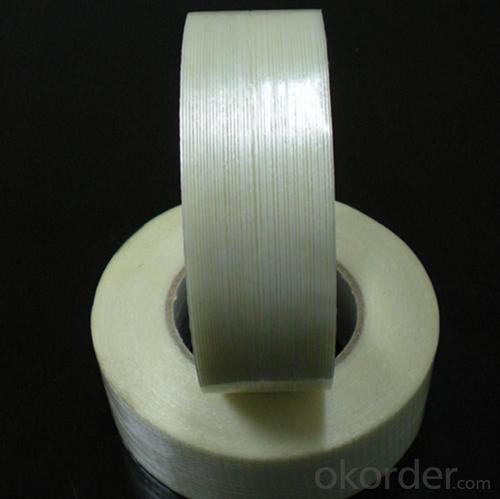

High Quality Fiberglass Tape FGT-200 for Heat Machine Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Genaral Information Of High Quality Fiberglass Tape FGT-200

1. Filament / fiberglass tape is with PET film and bi-directional fiberglass.

2. The tape is with high tensile strength, used for palletizing, holding, bundling, reinforcing, heavy duty packing, carton packing & sealing.

3. Standard cut roll packing: one roll per plastic bag, then into cartons. We can also offer special packing as per customer's requirements, such as label, core printing and sticker.

acking: Bi-directional Fiberglass + PET film

Adhesive: Hot melt rubber based adhesive

Total Thickness (adhesives + backing): 200micron

Initial Tack: more than 20# steel ball

Tensile Strength: more than 120N/25mm

Peel Adhesion: 13 N/25mm

Holding power: not less than 50h (1kg/25mm)

Mesh: 6/6

Temperature resistance: 60C

Elongation: 1.00%

Sizes:

Jumbo Roll: 1.02 x 1000m

Cut Roll: As per customer's requirement

Packing Of High Quality Fiberglass Tape FGT-200

Core I.D.: 3” (76mm?1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application Of High Quality Fiberglass Tape FGT-200

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

Service Of High Quality Fiberglass Tape FGT-200

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

Handing and Storage Of High Quality Fiberglass Tape FGT-200

Handling procedures:Caution with edge of sheet. After using this sheet, wash hands.

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Stability and Reactivity Of High Quality Fiberglass Tape FGT-200

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

Transport Information Of High Quality Fiberglass Tape FGT-200

Not a hazardous material for DOT shipping.

UN:None

Packaging sign:According to the buyer

Packaging Category:No information found/According to the buyer.

Shipping Marks: According to the buyer

Remarks Of High Quality Fiberglass Tape FGT-200

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: 10%; Width: 3mm; Length: Cut Roll & Log Roll 0.3m, Jumbo Roll 0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Are there any specific instructions for reusing packaging tape?

- Yes, there are some specific instructions for reusing packaging tape. Here are a few guidelines to follow: 1. Carefully remove the tape from the package: When you receive a package, try to remove the tape as gently as possible to avoid tearing or damaging it. 2. Clean the tape: If the tape has any dirt, dust, or residue on it, you can clean it by wiping it gently with a damp cloth. Make sure to let it dry completely before reusing. 3. Check the adhesive strength: Before reusing the tape, check if the adhesive is still strong enough to hold securely. If it has lost its stickiness or if it is damaged, it is recommended to discard it and use a new piece of tape. 4. Store the tape properly: To keep the tape in good condition for future use, store it in a cool, dry place away from direct sunlight. This will help prevent it from drying out or becoming brittle. 5. Use it for light to medium-duty tasks: Reused packaging tape may not be as strong as new tape, so it is best suited for light to medium-duty tasks. Avoid using it for heavy items or applications where a stronger adhesive is required. Remember, while reusing packaging tape is a great way to reduce waste, it is important to prioritize functionality and security. If the tape is damaged or loses its adhesive strength, it is best to replace it with a new piece to ensure your package is properly sealed.

- Q: Is packaging tape transparent?

- Indeed, transparency can be found in packaging tape. Various forms of packaging tape are manufactured using clear substances like polypropylene or acrylic, which enable them to possess a see-through quality. The advantage of this transparency lies in its ability to allow users to effortlessly view the contents of a package without the need for unwrapping. Furthermore, transparent packaging tape is often favored in situations where a polished and professional appearance is desired, as it effortlessly blends with diverse packaging materials. Nonetheless, it is worth mentioning that not all packaging tapes possess transparency, as there are also options available in colored or printed variations that cater to specific purposes or branding requirements.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Yes, packaging tape can be used for sealing metal containers or boxes. Packaging tape is typically made with a strong adhesive that adheres well to various surfaces, including metal. It provides a secure and reliable seal, keeping the contents of the metal container or box protected and preventing any unwanted opening or damage during transportation or storage. However, it is important to ensure that the surface of the metal container or box is clean and free from any grease or dirt for optimal adhesion. Additionally, if the metal container or box is exposed to extreme temperatures or harsh conditions, it may be advisable to use a tape specifically designed for those environments to ensure a more durable seal.

- Q: Can packaging tape be used for sealing packages with delicate fabrics or clothing?

- Yes, packaging tape can be used for sealing packages with delicate fabrics or clothing. However, it is important to exercise caution and take certain precautions to protect the delicate items. Here are a few tips to ensure safe packaging: 1. Use a wide, clear packaging tape: Opt for a wide tape that allows for a larger surface area of adhesion. Clear tape is preferable as it reduces the risk of leaving any visible residue or marks on the fabric. 2. Double-layer the tape: Apply two layers of packaging tape to provide extra strength and security to the package. This will help prevent the tape from accidentally peeling off during transit. 3. Wrap the delicate items securely: Before sealing the package, make sure to wrap the delicate fabrics or clothing in a protective layer, such as tissue paper or bubble wrap. This additional layer will act as a buffer and safeguard the items from any potential damage caused by the tape. 4. Avoid excessive tension: While sealing the package, be careful not to pull too tightly on the tape. Applying excessive tension may cause the fabric to stretch or distort, potentially damaging the delicate item. 5. Consider alternative options: If the delicate item is particularly fragile or valuable, it may be worth considering alternative packaging materials, such as acid-free tissue paper or garment bags. These options provide even more protection and are specifically designed for preserving delicate fabrics and clothing. Ultimately, while packaging tape can be used for sealing packages with delicate fabrics or clothing, it is essential to handle the items with care and take appropriate measures to minimize any potential damage during the packaging process.

- Q: What is the best way to apply packaging tape?

- The best way to apply packaging tape is to first ensure that the surface is clean and dry. Start by holding the tape dispenser at a slight angle and pressing firmly on the surface, moving the dispenser smoothly in a straight line. Avoid stretching or folding the tape as it can weaken its adhesive properties. Finally, use a sharp object to cut the tape cleanly, ensuring a secure and professional seal.

- Q: Does packaging tape come in different colors?

- Packaging tape indeed comes in various colors. Although clear is the most commonly used color, there is a wide range of colors to choose from to cater to different requirements and personal preferences. For instance, red, blue, green, yellow, and black are some examples of colored packaging tape. These colored tapes serve multiple purposes, such as color-coding packages, indicating priority shipments, or adding a vibrant touch to your packaging. Moreover, colored packaging tape offers versatility as it can be used for decorative or artistic intentions, making it a suitable choice for both practical and creative uses.

- Q: Is packaging tape safe to use on plastic cutting mats?

- Before using packaging tape on plastic cutting mats, it is important to take a few factors into consideration. Firstly, make sure that the cutting mat is made of a durable and food-safe material. Some lower quality mats may get scratched or torn when tape is applied, so it is advisable to check the manufacturer's recommendations. Secondly, think about why you want to use packaging tape on the cutting mat. If it is for temporary storage or transportation, packaging tape can provide a secure seal. However, if the tape will come into direct contact with food or be used during food preparation, it is best to avoid using packaging tape. The adhesive residue from the tape could transfer onto the food or contaminate the cutting surface, which could be a health risk. In such cases, it is better to use food-grade or specialized tape that is specifically designed for cutting mats or food preparation surfaces. In conclusion, although packaging tape can be safe to use on plastic cutting mats, it is crucial to consider the quality of the mat, the purpose of using the tape, and potential food safety concerns. Always prioritize the safety and hygiene of your food preparation surfaces by choosing the appropriate tape.

- Q: Can packaging tape be used for sealing packages with confidential or sensitive contents?

- Packaging tape can be used for sealing packages with confidential or sensitive contents, but it is not the most secure option. For enhanced security, it is advisable to consider using tamper-evident or tamper-resistant packaging solutions, such as security tape or specialized envelopes, to provide an additional layer of protection against unauthorized access or tampering.

- Q: What's the tape for sealing tape?

- In order to obtain better comprehensive performance, the multilayer composite method is usually used in the process of production. BOPP can be combined with a variety of different materials to meet special application needs. Such as BOPP and LDPE (CPP), PE, PT, PO and PVA composite are highly resistance gas, humidity resistance, transparency, high and low temperature resistance, steam resistance and oil resistance, different composite membrane can be applied to oily food, delicious food, dry food, food, cooking cooked food, dipping MSG, pancakes, rice cake and other packaging.

- Q: Can packaging tape be used for sealing packages with automotive parts or accessories?

- Indeed, the utilization of packaging tape is applicable for the sealing of packages encompassing automotive parts or accessories. With its purpose in securely sealing packages, packaging tape effectively ensures the cohesion of packages containing automotive parts or accessories. Through its robust adhesive bond, it guarantees that the package remains sealed throughout transportation or storage. Moreover, packaging tape commonly exhibits resistance to moisture, a crucial quality when shipping automotive parts or accessories susceptible to water damage.

1. Manufacturer Overview

| Location | Dongguan, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 30.00% North America 10.00% South America 20.00% Eastern Europe 20.00% Northern Europe 10.00% Western Europe 10.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou Port |

| Export Percentage | 10% - 20% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | bopp tape, PE foam tape, EVA foam tape, cloth tape, masking tape, PET tape, kraft paper tape |

| Product Price Range | High; Average |

Send your message to us

High Quality Fiberglass Tape FGT-200 for Heat Machine Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords