Tesa PVC Packaging Tape - Masking Tape Temperature Resistance 90 SGS & ISO9001

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

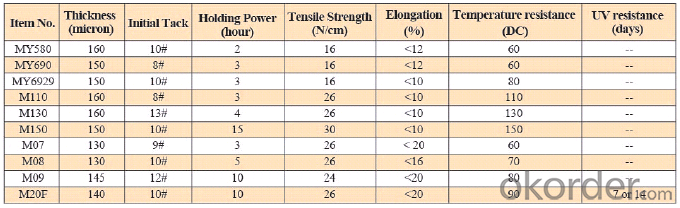

Typical Physical Reports of Masking Tape

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1800mm; width according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: What are the advantages of using packaging tape over other sealing methods?

- There are several advantages of using packaging tape over other sealing methods. Firstly, packaging tape provides a strong and secure seal that can withstand the rigors of shipping and handling. It is designed to adhere to various surfaces, including cardboard, plastic, and metal, ensuring that the package remains intact throughout its journey. Secondly, packaging tape is easy to use and can be quickly applied to seal a package. Unlike other sealing methods such as glue or staples, tape does not require any additional tools or equipment. This saves time and allows for efficient packaging processes. Furthermore, packaging tape offers versatility in terms of size and strength. It is available in different widths and thicknesses, allowing for customization based on the specific needs of the package. Whether you are sealing a small envelope or a large box, there is a packaging tape option that suits your requirements. Another advantage of packaging tape is its cost-effectiveness. Compared to other sealing methods, tape is generally more affordable. It offers a cost-efficient solution for businesses and individuals who frequently ship or package items. In addition, packaging tape is tamper-evident, providing an added layer of security. Once the tape is applied, any attempt to tamper with the package will be evident due to the broken or damaged tape seal. This helps to deter theft and provides peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable. It can be peeled off without leaving any residue or damaging the packaging materials. This is particularly important for packages that may require resealing or for recipients who may want to reuse the packaging. Overall, the advantages of using packaging tape over other sealing methods include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: Can packaging tape be used for sealing gardening or outdoor equipment?

- Indeed, gardening or outdoor equipment can be effectively sealed using packaging tape. Specifically engineered to securely seal boxes and packages, packaging tape proves itself as an excellent option for sealing outdoor gear like gardening tools, outdoor furniture, and other equipment. Its robust and long-lasting seal is capable of enduring outdoor conditions, including moisture and temperature fluctuations. Nevertheless, it is worth mentioning that if the equipment or packaging tape is expected to endure harsh weather conditions or prolonged outdoor usage, opting for specialized outdoor or weather-resistant tape would be more suitable to ensure enhanced durability and longevity.

- Q: How do I prevent packaging tape from yellowing over time?

- To prevent packaging tape from yellowing over time, it is essential to store it in a cool, dry, and dark place. Exposure to sunlight and humidity can accelerate the yellowing process. Additionally, using high-quality packaging tape made from materials resistant to discoloration can help maintain its original appearance for a longer period.

- Q: Is packaging tape easy to cut with scissors?

- Yes, packaging tape is generally easy to cut with scissors. The tape is designed to be easily cut with regular household scissors, making it convenient for various packaging needs. The combination of its thickness and adhesive properties allows for clean and precise cuts, ensuring that the tape can be easily managed and removed when necessary.

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. Packaging tape is designed to securely seal various types of packaging materials, including plastic clamshell packaging. It provides a strong adhesive bond that holds the clamshell packaging together and prevents it from opening during shipping or handling. Additionally, packaging tape is durable and tear-resistant, ensuring that the clamshell packaging remains sealed and protected throughout the entire distribution process.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. It provides a secure and reliable seal, helping to protect the contents during transit or storage.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Indeed, plastic pet carriers can be effectively sealed using packaging tape. This tape is specifically created to securely seal packages and boxes, offering a powerful adhesive bond. With proper application, it can successfully seal the entrances of plastic pet carriers, guaranteeing the safety of your beloved pet. Nevertheless, it is crucial to ensure an even and secure application of the tape to avoid any potential gaps or openings through which your pet could escape. Furthermore, it is advisable to periodically inspect the tape's integrity and reapply it if needed.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is generally designed to be easily removable without causing damage to surfaces. However, the ease of removal can vary depending on several factors such as the type and quality of the tape, the surface it is applied to, and the length of time it has been in place. Most packaging tapes are designed to adhere firmly to surfaces during transit or storage, ensuring that the package remains sealed and secure. However, they are also designed to be peeled off easily when needed, without leaving behind residue or causing damage. In most cases, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is typically formulated to have a good balance between adhesion and removability. This allows for easy removal without requiring excessive force or leaving behind sticky residue. However, there can be instances where the tape may be more difficult to remove, especially if it has been in place for an extended period or exposed to extreme temperature conditions. In such cases, it may be helpful to use heat (such as a hairdryer) to soften the adhesive, making it easier to peel off. It is worth noting that the ease of tape removal can also depend on the surface it is applied to. Smooth, non-porous surfaces like glass or metal are generally easier to clean without any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to avoid any potential damage. In conclusion, while packaging tape is generally easy to remove without damaging surfaces, it is important to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: What are the tapes for packing tape?

- Size, core, stationery, glue, wet water, leather tape, double sided tape series

- Q: Can packaging tape be used for sealing packages with perishable items?

- Using packaging tape to seal packages with perishable items is not recommended. Although it may create a temporary seal, it is not intended to withstand the specific difficulties that accompany packaging perishable goods. Items that can spoil, such as food or flowers, necessitate specialized packaging materials that offer insulation, temperature control, and protection against moisture or air leakage. These materials are purposely designed to safeguard perishable items throughout transportation and storage. Consequently, it is advisable to utilize suitable packaging materials like insulated bags, coolers, or specialized packaging solutions to seal packages containing perishable items, guaranteeing their freshness and quality.

Send your message to us

Tesa PVC Packaging Tape - Masking Tape Temperature Resistance 90 SGS & ISO9001

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords