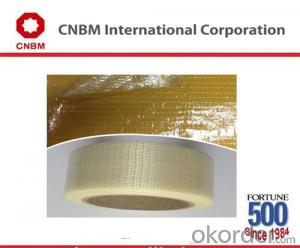

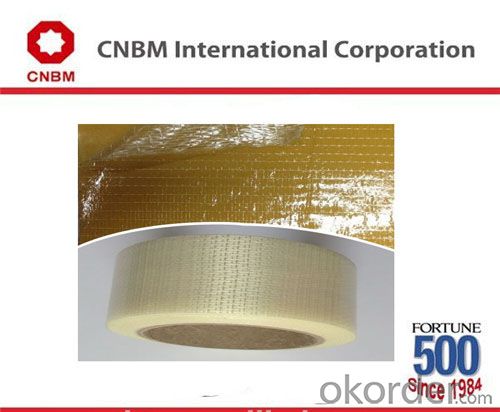

Cheap Packaging Tape Waterproof Self-Fusing Fiberglass Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

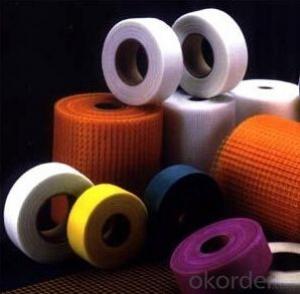

fiberglass self adhesive mesh tape

Adhesive: rubber based

color: transparen and others

thickness: 150-220mic

jumbo roll: 1.02m*1000m

Application:

used to guarantee maximum package security for heavy tabbing/seaming in the metal

fabricating industry.

Packaging & Delivery

| Packaging Details: | roll/shrink; 4 rolls/shrink; 6 rolls/shrink 24rolls/carton;36rolls/carton;48rolls/carton;72rolls/carton Promotional Filament Fiberglass Tape |

| Delivery Detail: | 15-30days after deposit received,Filament Fiberglass tape |

Our Services:

1. We have good and professional team

2. We accept any drawings or your samples to develop new product

3. Any small problems will be solved at the most prompt time

4. We always offer relative technical support, quick response, all your inquire will replied within 24 hours

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: 2014, how can I sell the tape better?

- Fourth, the background of your company must say company influence and company history,Fifth, the market prospects and profit margins, regardless of the price of your products is how much of that is not a problem, and if you have a small list of hands, you can put the list to be introduced to customers, these are my experience to sell, can only give you a reference, are different for each personal selling, to try to know,

- Q: What are the advantages of using packaging tape over other sealing methods?

- There are several advantages of using packaging tape over other sealing methods. Firstly, packaging tape provides a strong and secure seal that can withstand the rigors of shipping and handling. It is designed to adhere to various surfaces, including cardboard, plastic, and metal, ensuring that the package remains intact throughout its journey. Secondly, packaging tape is easy to use and can be quickly applied to seal a package. Unlike other sealing methods such as glue or staples, tape does not require any additional tools or equipment. This saves time and allows for efficient packaging processes. Furthermore, packaging tape offers versatility in terms of size and strength. It is available in different widths and thicknesses, allowing for customization based on the specific needs of the package. Whether you are sealing a small envelope or a large box, there is a packaging tape option that suits your requirements. Another advantage of packaging tape is its cost-effectiveness. Compared to other sealing methods, tape is generally more affordable. It offers a cost-efficient solution for businesses and individuals who frequently ship or package items. In addition, packaging tape is tamper-evident, providing an added layer of security. Once the tape is applied, any attempt to tamper with the package will be evident due to the broken or damaged tape seal. This helps to deter theft and provides peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable. It can be peeled off without leaving any residue or damaging the packaging materials. This is particularly important for packages that may require resealing or for recipients who may want to reuse the packaging. Overall, the advantages of using packaging tape over other sealing methods include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Yes, packaging tape can be used for sealing plastic flower pots. Packaging tape is a versatile adhesive tape that is commonly used for sealing boxes and packages. Its strong adhesive properties make it suitable for securing plastic flower pots and preventing any leaks or spills. However, it is important to ensure that the surface of the plastic flower pot is clean and dry before applying the tape, as any dirt or moisture may affect its adhesion. Additionally, it is worth noting that there are specific tapes designed for sealing or repairing plastic materials, which may offer better performance and durability when used on plastic flower pots.

- Q: Can packaging tape be used for sealing plastic containers?

- Yes, packaging tape can be used for sealing plastic containers. It is a commonly used method to secure and seal plastic containers, ensuring their contents remain intact and protected.

- Q: What kind of material is used in this kind of tape? What are its features? How are they made? And so on!The more detailed you write, the better!

- Look, there's no poison. Look at the sticky stuff above. What's that?

- Q: Can packaging tape be used for sealing packages with heavy items?

- Yes, packaging tape can be used for sealing packages with heavy items. Packaging tape is specifically designed to provide strong adhesion and durability, making it suitable for securing packages containing heavy items. It is made from a strong material like polypropylene or acrylic, which ensures that it can withstand the weight and pressure of heavy items without easily tearing or coming loose. Additionally, packaging tape often has a strong adhesive backing that bonds well with various surfaces, ensuring a secure seal. However, it is important to choose the appropriate width and thickness of packaging tape to ensure proper sealing for heavy packages.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: What are the best practices for storing packaging tape rolls?

- The best practices for storing packaging tape rolls include: 1. Keep the tape rolls in a cool and dry environment: It is important to store packaging tape rolls away from direct sunlight and humidity. Extreme temperatures can cause the tape to become less effective and lose its adhesive properties. 2. Store the rolls upright: Storing the rolls upright helps maintain their shape and prevents them from getting squished or damaged. This also makes it easier to access and use the tape when needed. 3. Use a tape dispenser: Investing in a tape dispenser is a great practice for storing packaging tape rolls. Dispensers not only keep the rolls organized but also protect the tape from dust, dirt, and accidental damage. 4. Seal the rolls properly: Ensure that the tape rolls are securely sealed after use. This prevents dust and debris from accumulating on the adhesive side and maintains the tape's effectiveness for future use. 5. Keep an inventory of tape rolls: It is useful to keep track of how many tape rolls you have in stock and their respective sizes. This helps in planning and restocking when needed, avoiding any inconvenience or delays during packaging. 6. Avoid storing near chemicals or sharp objects: Packaging tape rolls should be kept away from any chemicals, solvents, or sharp objects that could potentially damage the tape or compromise its adhesive properties. By following these best practices, you can ensure that your packaging tape rolls remain in good condition and are readily available for use whenever needed.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Yes, packaging tape can be used for sealing construction materials or tools, but it may not provide as strong or durable of a seal as other specialized tapes designed specifically for construction purposes.

- Q: I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

- I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

Send your message to us

Cheap Packaging Tape Waterproof Self-Fusing Fiberglass Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords