UV Resistant PVC Electrical Tape with 100 Micron Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With 100 Mircon Thickness

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With 100 Mircon Thickness

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With 100 Mircon Thickness

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With 100 Mircon Thickness

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

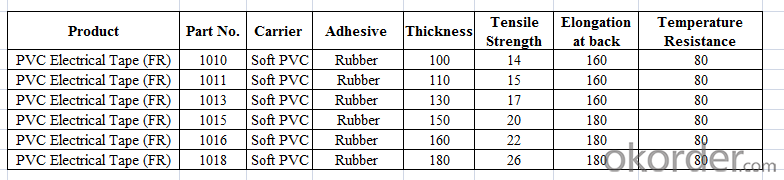

Technical Data of PVC Electrical Tape With 100 Mircon Thickness

Product Show of PVC Electrical Tape With 100 Mircon Thickness

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Does packaging tape have a specific weight capacity?

- Yes, packaging tape does have a specific weight capacity. The weight capacity of packaging tape depends on its thickness, width, and quality. Generally, packaging tapes are designed to securely seal boxes and packages, and their weight capacity is determined by their adhesive strength and durability. Most standard packaging tapes have a weight capacity of around 20 to 30 pounds. However, heavy-duty packaging tapes are available that can handle weights of up to 50 pounds or more. It is important to consider the weight of the package or box being sealed and choose a packaging tape that can handle the specific weight capacity to ensure a secure and reliable seal.

- Q: How do I prevent packaging tape from wrinkling?

- Here are some steps you can take to prevent packaging tape from wrinkling: 1. Utilize a tape dispenser: Using a tape dispenser aids in achieving a smooth application of the tape, reducing the likelihood of wrinkling. It also grants better control during taping, making it easier to keep the tape straight and taut. 2. Apply the tape tightly: When applying the tape, pull it firmly as you adhere it. This prevents any slack or loose areas that may cause wrinkling. Be cautious not to stretch the tape excessively, as this could diminish its adhesive properties. 3. Opt for the appropriate tape type: Different types of packaging tape possess varying adhesive properties and thicknesses. Selecting a high-quality tape specifically designed for packaging can minimize wrinkling. Additionally, consider using tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, ensure that the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or adhere improperly. Thoroughly clean the surface and allow it to dry before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Refrain from using the tape in extremely cold or hot environments. If possible, store the tape in an area with controlled temperature before usage. 6. Apply pressure: After applying the tape, use your hand or a roller to exert pressure on it, ensuring proper adhesion. This helps smooth out any potential wrinkles or bubbles and ensures a secure attachment of the tape. By following these suggestions, you can significantly diminish the likelihood of packaging tape wrinkling, resulting in a more orderly and secure package.

- Q: How do I remove packaging tape without damaging the surface?

- To remove packaging tape without damaging the surface, you can try using a hairdryer to gently heat the tape, which will make it easier to peel off. Alternatively, you can use a small amount of rubbing alcohol or vinegar to dissolve the adhesive before carefully peeling it off. It's important to be patient and take your time to prevent any potential damage to the surface.

- Q: Does packaging tape come in different eco-friendly options?

- Yes, packaging tape is available in different eco-friendly options. Many companies now offer packaging tape made from recycled and biodegradable materials, such as paper or plant-based adhesives. These eco-friendly alternatives help reduce the environmental impact of packaging materials.

- Q: Does packaging tape have a specific shelf life?

- Yes, packaging tape does have a specific shelf life. The shelf life of packaging tape typically depends on the type and quality of the tape. However, most packaging tapes have a shelf life of around 1 to 2 years if stored properly in a cool, dry place. It is always recommended to check the manufacturer's guidelines for specific information on the shelf life of a particular packaging tape.

- Q: How do I prevent packaging tape from sticking to itself?

- To prevent packaging tape from sticking to itself, you can try folding over a small portion of tape at the end, creating a tab that will make it easier to peel off when needed. Additionally, you can use a dispenser or a cutting tool to cleanly cut the tape, minimizing the chances of it sticking to itself.

- Q: What are the common sizes of packaging tape?

- The common sizes of packaging tape typically range from 1.88 inches to 3 inches in width, while the length can vary depending on the brand and type of tape.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: What is the profit margin of the transparent tape for packaging?

- Now, many of the tapes are closed and the profits are too transparent

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages containing jewelry or valuables. It provides a secure and reliable seal, ensuring that the contents of the package are protected during transit.

Send your message to us

UV Resistant PVC Electrical Tape with 100 Micron Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords