Custom Business Packaging Tape - PVC Electrical Insulation Tape Waterproof Colored

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

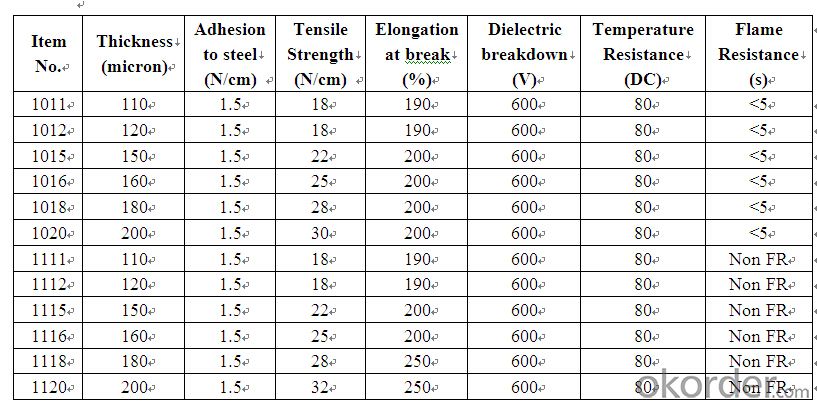

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Can packaging tape be used for sealing musical instruments or equipment?

- Packaging tape is not recommended for sealing musical instruments or equipment. It may not provide adequate protection or support, and could potentially damage the instrument or equipment. It is best to use specialized products designed specifically for sealing and protecting musical instruments or equipment.

- Q: Is packaging tape safe to use on delicate items?

- The safety of using packaging tape on delicate items varies depending on the type of tape and how it is applied. Certain packaging tapes are specifically made for delicate items, minimizing the risk of damage through features like low tack adhesive or gentle release properties. These tapes, commonly known as "low-tack" or "gentle" tapes, are often transparent. When using packaging tape on delicate items, it is crucial to apply it carefully and securely, avoiding excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure it does not cause harm or leave residue. Moreover, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape. This extra layer of cushioning and protection can be beneficial. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most suitable packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: Can packaging tape be used for sealing packages with heavy items?

- Yes, packaging tape can be used for sealing packages with heavy items. However, it is important to ensure that the tape is strong and durable enough to withstand the weight and provide proper sealing. It is recommended to use heavy-duty packaging tape specifically designed for sealing heavy packages to ensure secure packaging.

- Q: Can packaging tape be used for sealing recreational or outdoor gear?

- Yes, packaging tape can be used for sealing recreational or outdoor gear. It provides a strong and durable bond, making it suitable for securing and sealing various types of gear such as tents, sleeping bags, or backpacks. However, it's important to consider the specific requirements and conditions of the gear being sealed, as there may be more specialized options available for certain items.

- Q: Does packaging tape come in different textures?

- Yes, packaging tape does come in different textures. While the most common type of packaging tape is smooth and glossy, there are also textured variations available. Some examples of textured packaging tape include rubberized tapes, which have a soft and grippy texture, and paper-based tapes, which have a rougher texture similar to masking tape. These textured tapes are often used for specific purposes, such as providing extra grip or adhering to difficult surfaces. However, it's important to note that textured packaging tapes may have different adhesive properties and may not be suitable for all applications.

- Q: Can packaging tape be used for sealing plastic folders?

- Yes, packaging tape can be used for sealing plastic folders.

- Q: What are the common brands of packaging tape?

- Scotch, Duck, 3M, Gorilla, and Uline are among the commonly known brands of packaging tape. These brands have gained recognition for their resilient nature, strong adhesion, and user-friendly characteristics. They offer a diverse range of choices, including clear, tan, and colored tapes, as well as various widths and lengths to cater to different packaging requirements. Furthermore, these brands frequently offer alternatives for different packaging materials such as cardboard boxes, plastic bags, and bubble wrap. It is crucial to opt for a reputable brand while selecting packaging tape to guarantee the dependable and secure sealing of packages.

- Q: Can packaging tape be used for sealing electrical or wiring components?

- No, packaging tape should not be used for sealing electrical or wiring components. It does not provide the necessary insulation or protection required for electrical components. It is recommended to use appropriate electrical tape or other approved methods to seal and protect electrical or wiring components.

- Q: What are the different types of packaging tape available?

- There are several different types of packaging tape available, each designed for specific purposes and applications. Here are some common types: 1. Clear packaging tape: This is the most commonly used type of packaging tape. It is transparent and provides a strong adhesive bond for sealing boxes and packages. Clear tape is versatile and suitable for a wide range of applications. 2. Brown packaging tape: Also known as "brown tape" or "packing tape," this type of tape is made from brown or tan-colored material, usually reinforced with fiberglass. It offers excellent strength and durability for securing heavy or bulky packages. 3. Masking tape: While not specifically designed for packaging, masking tape can be used for light-duty sealing or labeling purposes. It is easily removable and leaves no residue, making it ideal for temporary applications. 4. Duct tape: Often recognized for its strength and versatility, duct tape is not primarily designed for packaging but can be used in certain situations. It has a strong adhesive bond and is known for its ability to stick to a wide range of surfaces, including uneven or rough ones. 5. Filament tape: This type of tape is reinforced with fiberglass filaments, providing exceptional strength and resistance. Filament tape is commonly used for bundling or reinforcing heavy or irregularly shaped items. 6. Double-sided tape: Unlike other types of packaging tape, double-sided tape has adhesive on both sides and is used for various applications, such as bonding two surfaces together or mounting objects. 7. Kraft paper tape: Made from a renewable resource, kraft paper tape is an eco-friendly alternative to plastic tapes. It is water-activated and requires moistening before application. Kraft paper tape provides a strong seal and is often used for sealing cartons or packages containing valuable or fragile items. 8. Colored packaging tape: This type of tape is available in various colors and is commonly used for color-coding packages, labeling, or adding aesthetic appeal to packages. These are just some of the different types of packaging tape available in the market. Each type has its own unique characteristics and is suitable for specific packaging needs. When choosing the appropriate tape, it is important to consider factors such as the weight and nature of the package, the environment it will be exposed to, and any specific requirements or regulations that may apply.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is generally designed to be easily removable without causing damage to surfaces. However, the ease of removal can vary depending on several factors such as the type and quality of the tape, the surface it is applied to, and the length of time it has been in place. Most packaging tapes are designed to adhere firmly to surfaces during transit or storage, ensuring that the package remains sealed and secure. However, they are also designed to be peeled off easily when needed, without leaving behind residue or causing damage. In most cases, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is typically formulated to have a good balance between adhesion and removability. This allows for easy removal without requiring excessive force or leaving behind sticky residue. However, there can be instances where the tape may be more difficult to remove, especially if it has been in place for an extended period or exposed to extreme temperature conditions. In such cases, it may be helpful to use heat (such as a hairdryer) to soften the adhesive, making it easier to peel off. It is worth noting that the ease of tape removal can also depend on the surface it is applied to. Smooth, non-porous surfaces like glass or metal are generally easier to clean without any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to avoid any potential damage. In conclusion, while packaging tape is generally easy to remove without damaging surfaces, it is important to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

Send your message to us

Custom Business Packaging Tape - PVC Electrical Insulation Tape Waterproof Colored

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches