Custome Packaging Tape Uline - BOPP Bag Sealing Tape for Various Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

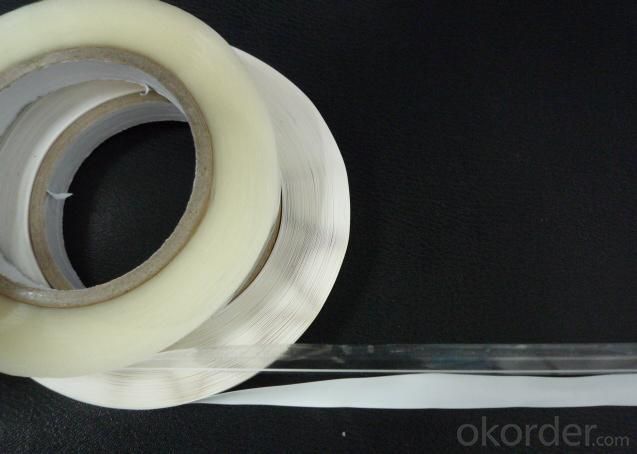

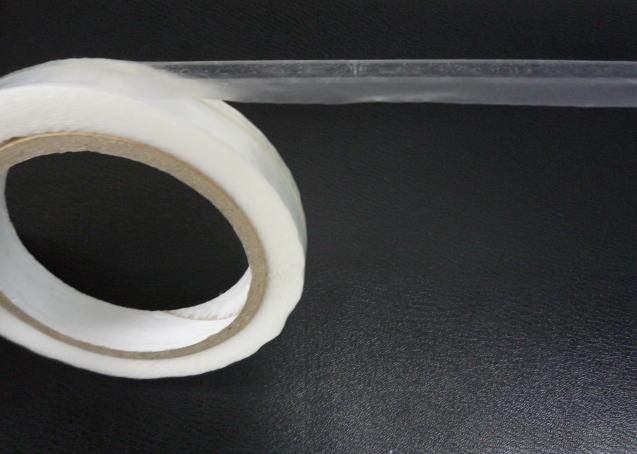

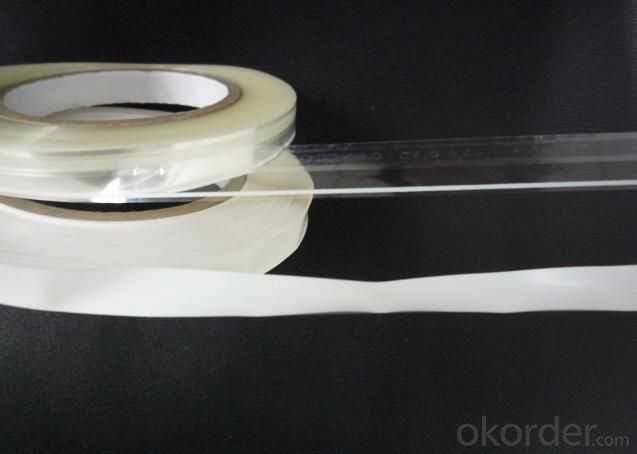

General Information Of Packing Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Item No BG-15P

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/7mm (middle glue)

Packing Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Core I.D.: 3” (76mm?1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

Service Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

Handing and Storage OfBOPP Bag Sealing Tape Used For Sealing In Various Industries

Handling procedures:Caution with edge of sheet. After using this sheet, wash hands.

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Stability and Reactivity Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

Transport Information Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Not a hazardous material for DOT shipping.

UN:None

Packaging sign:According to the buyer

Packaging Category:No information found/According to the buyer.

Shipping Marks: According to the buyer

Remarks Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: 10%; Width: 3mm; Length: Cut Roll & Log Roll 0.3m, Jumbo Roll 0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Indeed, plastic toolboxes can be effectively sealed using packaging tape. Specifically crafted to securely seal boxes and packages, packaging tape exhibits versatility by being suitable for various materials, including plastic. It delivers a robust and long-lasting seal capable of enduring regular handling and transportation. Nevertheless, for extended storage or heavy-duty purposes, it is advisable to opt for a more robust and specialized tape, like duct tape or strapping tape, as they provide enhanced durability and adhesion.

- Q: Can packaging tape be used for sealing furniture or home goods?

- Yes, packaging tape can be used for sealing furniture or home goods. Packaging tape is designed to provide a secure and strong seal, making it suitable for various purposes including sealing boxes and packages. When used on furniture or home goods, packaging tape can help keep the item protected during transportation or storage. It is important to ensure that the tape is applied properly and that it does not damage the surface or leave any residue. Additionally, depending on the weight and size of the item, it might be more appropriate to use specialized tapes or techniques for sealing furniture or home goods to ensure maximum protection.

- Q: Does packaging tape come in different allergen-free options?

- Yes, packaging tape is available in various allergen-free options. Many manufacturers offer packaging tapes that are specifically designed to be hypoallergenic and suitable for individuals with allergies or sensitivities. These tapes are typically free from common allergens such as latex, gluten, and certain chemical irritants. It is important to check the product description or contact the manufacturer to ensure that the packaging tape meets your specific allergen-free requirements.

- Q: How does packaging tape perform when exposed to sunlight?

- Packaging tape generally does not perform well when exposed to sunlight for extended periods of time. Sunlight contains ultraviolet (UV) rays which can cause the tape to deteriorate and lose its adhesive properties. Over time, the tape may become brittle, yellow, and start to peel off. The heat generated by the sunlight can also affect the tape's performance, causing it to melt or deform. Therefore, it is recommended to store packages with packaging tape in a cool, dark place to maintain its effectiveness and prevent any potential damage caused by sunlight exposure.

- Q: Can packaging tape be used for sealing glass or delicate items?

- Packaging tape is indeed suitable for sealing glass or delicate items; nevertheless, exercising caution and selecting the appropriate tape is of utmost importance. It is advisable to opt for a tape specifically designed for these materials when sealing glass or delicate items. Clear or transparent packaging tape is often a favorable choice as it securely seals without hindering visibility. Moreover, it is crucial to meticulously and evenly apply the tape to prevent any harm to the fragile surface. In conclusion, while packaging tape can be utilized for sealing glass or delicate items, it is essential to carefully choose the tape type and apply it with caution to guarantee the safety of the sealed items.

- Q: Does packaging tape come in different colors for organization purposes?

- Indeed, packaging tape is available in a range of colors to aid in organization. Numerous companies provide packaging tape in diverse hues like red, blue, green, yellow, and black. These distinct colors can be utilized to classify and arrange assorted package types or to distinguish between shipments bound for various locations. They prove particularly advantageous in warehouses or shipping departments where numerous packages necessitate effortless identification and sorting. Furthermore, colored packaging tape can serve decorative functions, such as embellishing gift wrapping or crafting visually captivating packaging for retail merchandise.

- Q: Can packaging tape be used for sealing pet food or treats?

- Yes, packaging tape can be used for sealing pet food or treats. It provides a strong and secure seal to keep the contents fresh and protected. However, it is important to ensure that the tape used is safe for pets, meaning it should be non-toxic and not contain any harmful substances that could potentially be ingested by the animals. It is recommended to use pet-safe packaging tape specifically designed for sealing pet food or treats, as it meets the necessary safety requirements and regulations.

- Q: I opened a shop in Taobao, to package the goods every day, is always to use the tape, I heard the tape is toxic, toxic if so how protection, what precautions, backup tape to keep it? Thank you ~ ~

- The adhesive used in the adhesive tape is very low in toxicity and has no side effects on the human body.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, make sure to use a high-quality tape that is specifically designed for packaging. Additionally, ensure that the surface of the package is clean and dry before applying the tape. Avoid using excessive force while pulling the tape, instead apply it smoothly and evenly. If you're still experiencing tearing, you can try using a tape dispenser or moistening the tape slightly to make it more pliable.

- Q: Can packaging tape be used for sealing packages with perishable items?

- Packaging tape is not ideal for sealing packages with perishable items. While it may provide a temporary seal, it is not designed to withstand the unique challenges that come with packaging perishable goods. Perishable items, such as food or flowers, require specialized packaging materials that can provide insulation, maintain temperature control, and prevent moisture or air leakage. These materials are designed specifically to protect perishable items during transportation and storage. Therefore, it is recommended to use appropriate packaging materials like insulated bags, coolers, or specialized packaging solutions when sealing packages containing perishable items to ensure their freshness and quality.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | produce single sided tapes,double sided tapes, masking tape, Opp tape |

| Product Price Range | High; Average |

Send your message to us

Custome Packaging Tape Uline - BOPP Bag Sealing Tape for Various Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords