Aluminum Foil Facing PVC Cable Ties for HVAC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Air Conditioning Tie Description

Air Conditioning Tie is designed for Air conditioning and used for HVAC system. Air conditioning tie: general and domestic brand air-conditioning manufacturer for cable tie. We can support you with different color like grey and whited or bule.

2.Main Features of Air conditioning tie

our Air conditioning tie with good and environmental quality of the products for the customer design research and development of different types, different colors and different quality of air conditioning products.

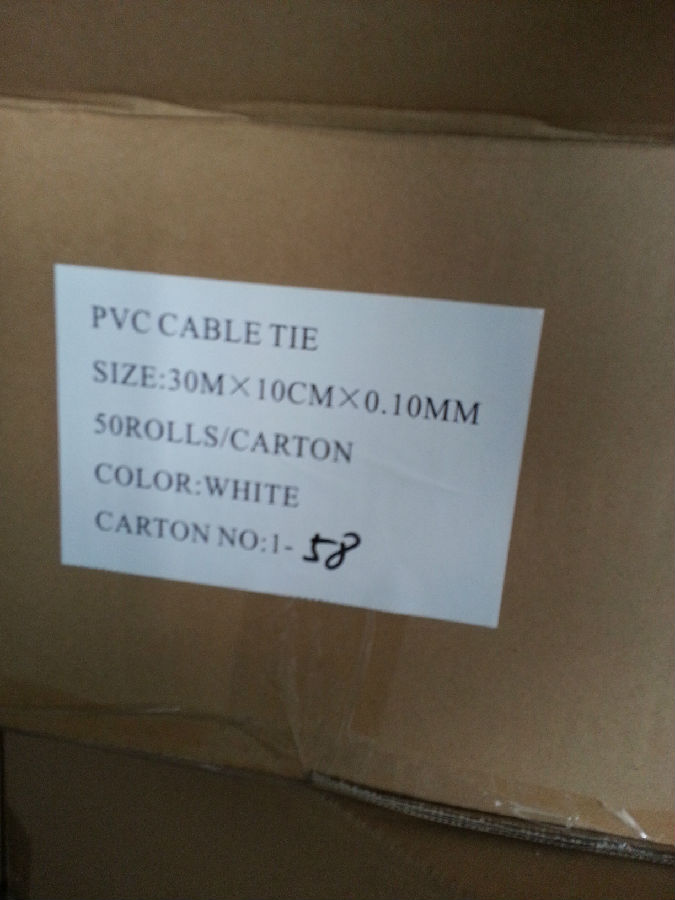

3.Air Conditioning Cable Tie Images

4.Air Conditioning Cable Tie Specification:

0.2 mm * 50 mm * 20 m (thickness * width * length)

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks about the proper way to store aluminum foil to keep it facing the right way for easy use.

- <p>To store aluminum foil facing the right way, first use up one side completely. Then, fold the remaining foil in half with the shiny side facing out. Place the folded foil back into the box or container, shiny side up. When you need to use it next, the shiny side will be facing you, making it easy to tear off. To keep it flat and wrinkle-free, you can place a piece of cardboard inside the box, or roll it around a clean, empty paper towel tube.</p>

- Q: Is it safe and effective to use aluminum foil as a facing material for making soup?

- <p>Using aluminum foil directly to make soup is not recommended. Aluminum foil is not designed for cooking food as it can react with acidic or alkaline ingredients, potentially releasing harmful substances into the food. It is also not heat resistant and can melt or warp when exposed to high temperatures. For safe and effective soup making, use materials specifically designed for cooking, such as stainless steel, enameled cast iron, or non-stick pots. These materials are safe for cooking and can withstand high temperatures without compromising the quality or safety of your soup.</p>

- Q: What are the potential health advantages of using food packaging that does not contain aluminum?

- <p>Yes, there are health benefits associated with using aluminum-free food packaging. Aluminum has been linked to potential health risks, including Alzheimer's disease and neurological disorders. By avoiding aluminum in food packaging, there's a reduced risk of exposure to this metal, which can leach into food, especially when heated. This can help minimize the intake of aluminum, potentially lowering the risk of related health issues. Aluminum-free packaging also reduces the environmental impact and is often more sustainable, contributing to overall health by promoting a cleaner environment.</p>

- Q: Is it safe to use recycled aluminum foil for cooking or baking purposes?

- <p>Recycled aluminum foil facing is not recommended for cooking or baking. While aluminum foil itself is safe for cooking and can be used to cover dishes or line baking sheets, recycled foil may have impurities or contaminants from previous uses. It may also be thinner and less durable, leading to potential tearing or puncturing, which can result in food contamination. For safety and food quality, it's best to use new, high-quality aluminum foil for cooking and baking.</p>

- Q: What are the chemical characteristics of the side of aluminum foil that faces outwards?

- <p>The chemical properties of the aluminum foil facing outward are primarily determined by its elemental composition, which is aluminum (Al). Aluminum is a lightweight, soft, and malleable metal with a silvery-white appearance. It is highly reactive and readily forms a thin, protective oxide layer (aluminum oxide) when exposed to air, which prevents further oxidation. This oxide layer is what gives aluminum foil its resistance to corrosion and its shiny appearance. Aluminum is also a good conductor of heat and electricity. The facing side of the aluminum foil may have slight differences in properties due to the manufacturing process, but fundamentally, it remains chemically similar to the rest of the aluminum foil.</p>

- Q: What are the potential health hazards linked to the use of aluminum foil facing?

- <p>The use of aluminum foil facing in construction or insulation can potentially pose health risks. Inhalation of aluminum dust can lead to respiratory issues, and long-term exposure may contribute to neurological problems. There's also a concern about the leaching of aluminum into food when using aluminum foil for cooking or food wrapping, which some studies suggest could be linked to Alzheimer's disease, although this link is not definitively proven. It's important to handle aluminum foil facing with care, ensuring proper ventilation and protective gear during installation to minimize health risks.</p>

- Q: This question asks for methods to clean oil stains from the aluminum foil facing of a surface.

- <p>To remove oil stains from aluminum foil facing, start by scraping off any excess oil with a plastic scraper or a butter knife. Then, mix a solution of warm water and dish soap. Apply the solution to the stained area and let it sit for a few minutes. Use a soft cloth or sponge to gently scrub the area. Rinse with warm water and dry thoroughly. For stubborn stains, you can use a mixture of baking soda and water to create a paste, apply it to the stain, let it sit for 15 minutes, then scrub and rinse. Always test cleaning methods on a small, inconspicuous area first to ensure no damage occurs.</p>

- Q: Is there a concern that aluminum from aluminum foil can seep into food during cooking or storage?

- <p>There is minimal risk of aluminum leaching from aluminum foil into food. Aluminum foil is generally safe for cooking and food storage when used properly. The risk increases with acidic or alkaline foods and high temperatures, but under normal cooking conditions, the amount of aluminum that could leach is negligible. However, it's best to avoid wrapping food in aluminum foil for long periods or at very high temperatures to minimize any potential exposure.</p>

- Q: This question asks for methods to prevent food from sticking to the aluminum foil surface during cooking.

- <p>To prevent food from sticking to the surface of aluminum foil when cooking, you can lightly coat the foil with a thin layer of cooking oil or non-stick spray before placing the food on it. This creates a barrier between the food and the foil. Additionally, ensure the foil is not torn or damaged, as this can cause food to stick. Using a heavier gauge foil can also help reduce sticking. Finally, avoid overcrowding the food on the foil, as this can cause it to stick due to uneven cooking and steam build-up.</p>

- Q: This question asks for the proper cleaning method for aluminum foil facing after it has been used.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a plastic scraper or the edge of a credit card. Avoid using metal scrapers as they can scratch the surface. Wipe the surface with a damp cloth and mild dish soap to remove any grease or grime. Rinse with warm water and dry thoroughly. For stubborn stains, you can use a mixture of baking soda and water to create a paste, apply it to the stain, let it sit for a few minutes, then scrub gently and rinse. Always check the manufacturer's instructions for any specific care requirements.</p>

Send your message to us

Aluminum Foil Facing PVC Cable Ties for HVAC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords