Aluminum Foil Facing PVC Cable Ties for Airconditioning

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Air Conditioning Tie Description

Air Conditioning Tie is designed for Air conditioning and used for HVAC system. Air conditioning tie: general and domestic brand air-conditioning manufacturer for cable tie. We can support you with different color like grey and whited or bule.

2.Main Features of Air conditioning tie

our Air conditioning tie with good and environmental quality of the products for the customer design research and development of different types, different colors and different quality of air conditioning products.

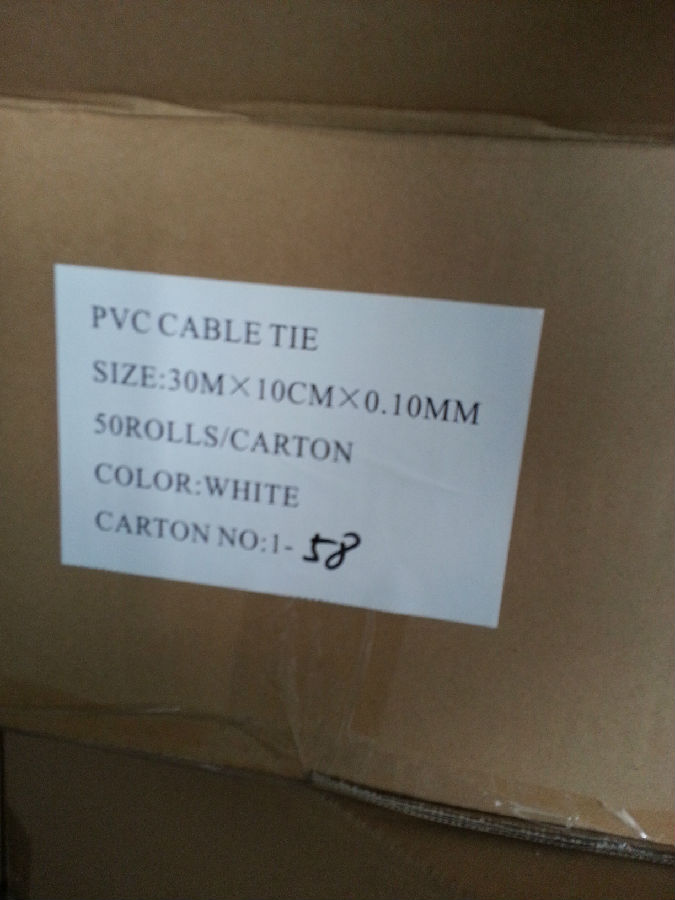

3.Air Conditioning Cable Tie Images

4.Air Conditioning Cable Tie Specification:

0.2 mm * 50 mm * 20 m (thickness * width * length)

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it safe to use aluminum foil facing to wrap food for the purpose of freezing?

- <p>Yes, you can use aluminum foil facing to wrap food for freezing. Aluminum foil is a good conductor of heat and can help food freeze quickly, preserving its freshness. It also protects the food from freezer burn and helps maintain its moisture. However, ensure that the foil is food-grade and avoid using it in direct contact with acidic or high-sodium foods, as these can cause a reaction with the aluminum. For best results, wrap the food tightly and securely to prevent air exposure, which can lead to freezer burn.</p>

- Q: This question asks for instructions on how to use aluminum foil as a wrapping material for food.

- <p>To use aluminum foil facing to wrap food, first ensure the foil is clean and free of tears. Cut a piece of foil large enough to fully cover the food item. Place the food in the center of the foil. Bring up the sides of the foil and fold them over the food, sealing the edges tightly to prevent air and moisture from entering. For more secure wrapping, double fold the edges or use a crimping technique. For items like fish or meat, you can also create a sealed pouch by folding the foil over the food, then folding the edges inward and crimping to close. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: This question asks for the correct method of wrapping food in aluminum foil, ensuring the shiny side faces outward.

- <p>To properly wrap food with aluminum foil, first ensure the shiny side of the foil faces outward. This side is non-stick and prevents food from sticking to the foil. Place the food in the center of a piece of foil large enough to cover it completely. Bring the edges of the foil together over the food, then fold and crimp the edges to seal tightly, creating a sealed pouch. This will help retain moisture and heat, and keep the food from sticking to the foil.</p>

- Q: This question asks for the steps to prepare aluminum foil for cooking, specifically how to set it up.

- <p>To prepare aluminum foil facing for cooking, first, cut a piece of aluminum foil larger than the cooking surface. Clean the foil to remove any dust or debris. Lightly grease the foil with cooking spray or oil to prevent food from sticking. Fold the edges of the foil up to create a shallow tray, ensuring the sides are high enough to contain any juices. Place the foil on the cooking surface, and you're ready to cook. Always handle the foil with utensils when hot to avoid burns.</p>

- Q: This question asks about the optimal methods for placing food in a microwave using aluminum foil, specifically focusing on the orientation of the foil's facing.

- <p>The best way to store food in a microwave using aluminum foil is to avoid using it altogether. Aluminum foil is not recommended for use in microwaves because it can cause sparks and potentially start a fire. Instead, use microwave-safe containers made of glass, ceramic, or plastic. If you must use aluminum foil, ensure it does not touch the microwave's walls or ceiling and that it is not in direct contact with the food. However, for safety and efficiency, it's best to use appropriate microwave-safe materials.</p>

- Q: Is it possible to use aluminum foil as a cooking utensil for stir-frying or sauteing food?

- <p>While aluminum foil can be used in some cooking applications, it is not recommended for stir-frying or sauteing due to its low melting point and potential for tearing. Aluminum foil can melt at high temperatures, which are often used in stir-frying and sauteing, leading to a fire hazard or uneven cooking. Additionally, the foil may tear or puncture easily, releasing aluminum particles into the food, which is not safe. Instead, use proper cookware like non-stick pans or stainless steel for these cooking methods.</p>

- Q: Is it safe to store food in a container where the aluminum foil is in direct contact with the food?

- <p>Storing food in a container lined with aluminum foil facing the food is generally safe as long as the foil is food-grade and the food is not acidic or high in salt. Aluminum foil is non-toxic and does not react with most foods. However, it's important to avoid using it with acidic foods like tomatoes or citrus fruits, as this can cause the foil to corrode and release aluminum. Also, avoid using it with high-salt foods as this can lead to a chemical reaction. Always ensure the foil is clean and undamaged to prevent any potential contamination.</p>

- Q: What are the considerations or safety measures to be aware of when using aluminum foil with a nonstick coating?

- <p>When using aluminum foil with a nonstick coating, it's important to avoid exposing it to high heat as the nonstick layer can degrade and release harmful fumes. Do not use it in broilers, on grills, or in the oven at temperatures exceeding 400掳F (204掳C). Additionally, refrain from cutting or puncturing the foil, as this can damage the nonstick surface. Avoid using metal utensils that might scratch the coating. Always follow the manufacturer's guidelines for safe use and temperature limits.</p>

- Q: This question asks for the method to wrap a hot pan using aluminum foil, with specific instructions on how the foil should face.

- <p>To wrap a hot pan with aluminum foil, first ensure the pan is stable and on a heat-resistant surface. Take a large piece of aluminum foil, about twice the size of the pan. Hold one corner of the foil and drape it over the pan, allowing the shiny side to face the pan. Gently press the foil against the pan, working your way around the edges to cover the entire surface. Ensure the foil is snug but not too tight to avoid tearing. The shiny side facing the pan will help reflect heat and protect the pan's surface. Be cautious while handling the hot pan and aluminum foil to avoid burns.</p>

- Q: Is it possible to recycle aluminum foil with a plastic facing in various countries?

- <p>Recycling practices for aluminum foil with plastic facing vary by country. In some regions, such as parts of Europe and North America, recycling facilities may accept and separate aluminum foil from its plastic lining. However, in other countries, this type of material might not be recyclable due to the difficulty in separating the aluminum from the plastic. It's essential to check local recycling guidelines, as the ability to recycle aluminum foil with plastic facing largely depends on the infrastructure and capabilities of local recycling centers.</p>

Send your message to us

Aluminum Foil Facing PVC Cable Ties for Airconditioning

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords