PUTZMEISTER Spectacle Plate Tungsten Carbide DN230

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

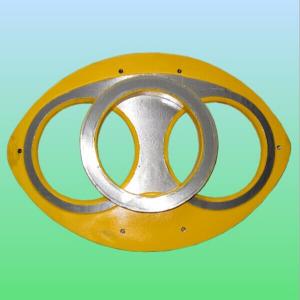

Product Name: Tungsten Carbide Spectacle Plate DN230

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Putzmeister concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

3. Package

Every 60pcs PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 according to customers request?

A4: Yes, we can produce PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Concrete pump spare parts may exhibit signs of wear and tear, which should not be overlooked. Some indicators include: 1. Surface damage: Cracks, dents, or scratches on pipes and hoses can signify wear and tear, particularly if they are extensive or deep. 2. Corrosion: Metal components like couplings or clamps may display signs of corrosion such as rusting or pitting, which can weaken the part and affect its functionality. 3. Leaks: Notable leaks in seals or gaskets can suggest wear and tear. Material degradation or improper installation can cause leaks, impacting the pump's efficiency and performance. 4. Decreased performance: Wear and tear in concrete pump spare parts can result in reduced overall performance. For instance, worn-out wear plates can diminish pumping capacity or increase energy consumption. 5. Heightened noise or vibrations: If noise levels or vibrations intensify while operating the concrete pump, it may indicate wear and tear in the spare parts. Imbalances, misalignments, or loose components can negatively affect the pump's performance and lifespan. 6. Excessive wear on moving parts: Moving parts like pistons or cylinders may exhibit excessive wear and tear, such as scoring or grooving on the surface. This can impede the smooth operation of the pump and potentially cause further damage if left unaddressed. Regular inspection and maintenance of concrete pump spare parts are vital to promptly identify and address any signs of wear and tear. Timely replacement or repair of worn-out components can prevent further damage, ensuring the concrete pump operates efficiently and safely.

- Q: What is the function of a concrete pump hopper agitator shaft bearing?

- The function of a concrete pump hopper agitator shaft bearing is to provide support and facilitate smooth rotation of the agitator shaft, ensuring effective mixing of the concrete in the hopper.

- Q: Can I get spare parts for concrete pump hydraulic cylinders and valves?

- Absolutely, spare parts for concrete pump hydraulic cylinders and valves are readily available. There is a wide range of companies and suppliers dedicated to supplying spare parts specifically for construction machinery, such as hydraulic cylinders and valves for concrete pumps. These spare parts can be conveniently obtained online or through nearby distributors. To ensure compatibility and proper operation of the spare parts, it is crucial to provide precise details about the make and model of your concrete pump. Furthermore, it is recommended to select reputable suppliers who offer authentic, top-notch spare parts for optimal performance and longevity.

- Q: What are the signs of a clogged or damaged hydraulic filter?

- Some signs of a clogged or damaged hydraulic filter may include decreased hydraulic system performance, increased noise or vibration, higher operating temperatures, and contamination of the hydraulic fluid.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: What is the function of a concrete pump control box?

- The concrete pump control box is a vital component of a concrete pump system, responsible for managing and controlling the operation of the pump to ensure a safe and efficient pumping process. By utilizing the control box, the operator can initiate, halt, and adjust the pumping speed of the concrete pump. Equipped with various control switches, knobs, and buttons, the control box facilitates control over different aspects of the pumping process. One of the key roles of the control box is to monitor the pressure and flow of the pumped concrete. This data is essential in guaranteeing that the concrete is pumped at the desired rate and consistency. Furthermore, the control box promptly notifies the operator of any irregularities or problems in the pumping system, such as clogs or blockages. Moreover, the control box may incorporate features like emergency stop buttons and safety interlocks to ensure the safety of both the operator and the equipment. Indicators and alarms may also be included to provide visual and audible cues regarding the pump's status and any potential issues that may arise. To summarize, the concrete pump control box's purpose is to equip the operator with the necessary controls and information to operate the concrete pump safely and efficiently. It ensures appropriate monitoring, control, and safety of the pumping process, ultimately leading to successful concrete placement.

- Q: Can concrete pump spare parts be inspected for dimensional accuracy before installation?

- Certainly, before installation, it is possible to examine concrete pump spare parts to ensure their dimensional accuracy. It is crucial to verify that the spare parts meet the necessary specifications and dimensions for proper functioning and compatibility with the concrete pump system. One can perform this inspection using a range of techniques, including visual examination, precise instrument measurements, and comparing dimensions to the manufacturer's specifications. This procedure aids in detecting any disparities or deviations in the spare parts' dimensions, enabling adjustments or replacement if needed. By inspecting spare parts for dimensional accuracy prior to installation, one can guarantee the seamless operation and durability of the concrete pump system.

- Q: How often should concrete pump electric motors be inspected and maintained?

- To ensure the optimal performance and longevity of concrete pump electric motors, it is crucial to regularly inspect and maintain them. It is advisable to have them checked at least once a year or after every 500-1000 operating hours, depending on which comes first. Furthermore, it is important to follow the manufacturer's guidelines and recommendations for regular maintenance. This may involve examining electrical connections for signs of damage or loose connections, cleaning dust and debris, lubricating moving components, and replacing worn-out parts. By adhering to a consistent inspection and maintenance schedule, one can avoid potential breakdowns, extend the motor's lifespan, and ensure efficient operation of the concrete pump.

- Q: How does a concrete pump hopper grate prevent clogs?

- Preventing clogs in the concrete pump system is a crucial function of the hopper grate. Acting as a filter, it permits only the necessary aggregate size to pass through, while capturing any excess debris or large particles that could cause blockages. Strategically placed openings or grids in the grate catch these unwanted materials. When pouring the concrete mixture into the hopper, the grate serves as a barrier. It allows only the appropriate material size to pass through, while obstructing any larger or undesirable debris. This ensures a smooth flow of concrete through the pump system, preventing any disruptions or jams during construction. Furthermore, the grate is typically constructed from durable materials like steel or high-density polyethylene. These materials are resistant to damage and wear, allowing the grate to withstand the high-pressure environment and continuous operation without deformation. Regular maintenance and cleaning of the hopper grate are also essential to prevent clogs. By inspecting and removing any accumulated debris or build-up on a regular basis, operators can ensure that the grate remains clear and fully functional, thereby preventing potential clogging issues. In conclusion, the concrete pump hopper grate acts as a filter to prevent clogs, allowing only the necessary aggregate size to pass through while capturing larger particles and debris. Its design and durable material ensure a smooth flow of concrete, minimizing the risk of blockages and maintaining construction efficiency.

- Q: What is the purpose of a concrete pump piston?

- The concrete pump piston serves to apply the essential pressure needed to propel the concrete mixture from the hopper and into the delivery pipeline. Its main responsibility is to generate the force necessary to propel the concrete throughout the system, effectively transporting it to the desired location. This is accomplished through the reciprocating movement of the piston, which creates suction on one side and pressure on the other, allowing the concrete to advance. In summary, the concrete pump piston plays a vital role in enabling the smooth and uninterrupted flow of concrete, making it an indispensable element in construction endeavors that demand accurate and timely concrete placement.

Send your message to us

PUTZMEISTER Spectacle Plate Tungsten Carbide DN230

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords