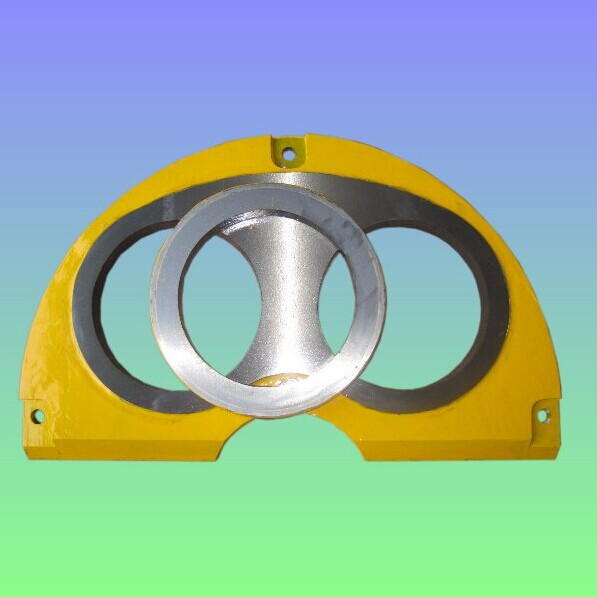

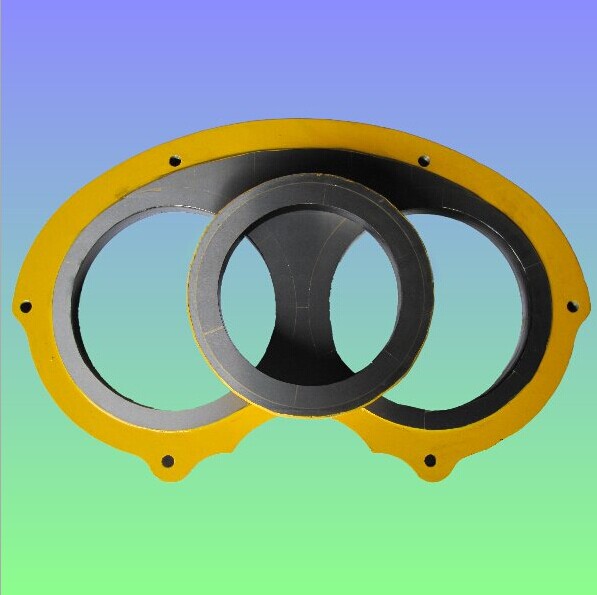

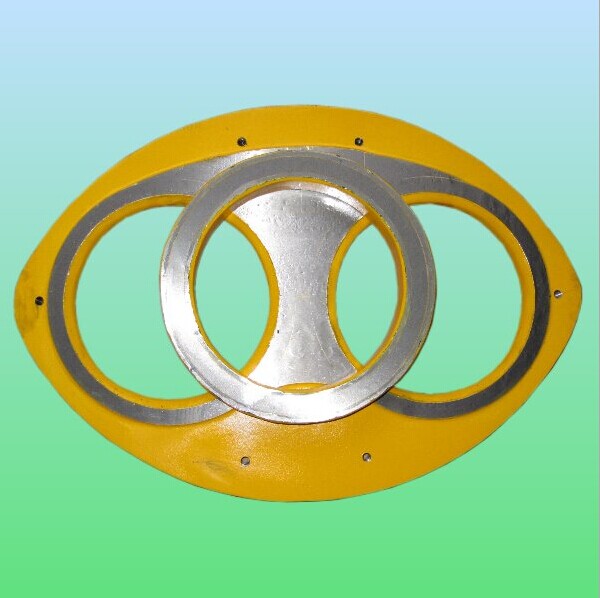

Tungsten Carbide Zoomlion Spectacle Plate DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Tungsten Carbide Zoomlion Spectacle Plate DN230

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade.

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Zoomlion concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our Tungsten Carbide Zoomlion Spectacle Plate DN230 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs Tungsten Carbide Zoomlion Spectacle Plate DN230 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Tungsten Carbide Zoomlion Spectacle Plate DN230 according to customers request?

A4: Yes, we can produce Tungsten Carbide Zoomlion Spectacle Plate DN230 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: How often should hopper agitator shaft seals be replaced in a concrete pump?

- Hopper agitator shaft seals in a concrete pump should be replaced as per the manufacturer's recommendations. However, as a general guideline, it is advisable to inspect and replace them annually or whenever signs of wear, leakage, or reduced performance are observed. Regular maintenance and proper lubrication can also help prolong the lifespan of these seals.

- Q: How can a faulty boom affect the concrete placement process?

- A faulty boom can significantly affect the concrete placement process. It can lead to uneven distribution of concrete, resulting in inconsistent concrete strength and quality. It may also cause the concrete to be placed in unintended areas or at incorrect heights, affecting the overall structural integrity of the project. Additionally, a faulty boom can pose a safety risk to workers and equipment involved in the concrete placement process.

- Q: How often should I replace concrete pump spare parts?

- The frequency of replacing spare parts for concrete pumps is determined by several factors, including the quality of the parts, how frequently they are used, and regular maintenance. It is generally recommended to regularly inspect and maintain the spare parts to detect any signs of wear or damage. As a precautionary measure, it is advisable to replace parts that display significant wear or are no longer functioning optimally. However, it is essential to adhere to the manufacturer's guidelines and recommendations for the specific model of concrete pump being used. Additionally, seeking advice from experienced professionals or technicians in the field can offer valuable insights into the expected lifespan of different spare parts and when replacements may be required.

- Q: Are there any specific guidelines for the disposal of packaging materials of concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of packaging materials of concrete pump spare parts. It is generally recommended to follow the local waste management regulations and guidelines provided by the respective authorities. Firstly, it is important to separate the different types of packaging materials such as cardboard boxes, plastic wraps, foam inserts, and any other materials used for packaging the concrete pump spare parts. This will enable efficient recycling or proper disposal of each material. Cardboard boxes can typically be recycled by flattening them and placing them in the designated recycling bins. Plastic wraps should also be separated and disposed of in specific recycling bins for plastics. Foam inserts, which are commonly used for protecting the spare parts, may not be recyclable in all areas and should be checked for specific recycling instructions. If recycling is not possible, foam inserts can be disposed of in regular waste bins. It is important to ensure that all packaging materials are free from any residual concrete or other hazardous substances before disposal. Any contamination should be properly cleaned or removed to prevent environmental pollution. If the packaging materials cannot be recycled or disposed of through regular waste management methods, it is recommended to contact local recycling centers or waste management facilities to inquire about specific disposal options for these materials. They may provide guidance or accept these materials for specialized processing or disposal. Overall, it is crucial to prioritize responsible waste management practices and comply with the specific guidelines provided by local authorities to ensure the proper disposal of packaging materials of concrete pump spare parts.

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- The pumping process can be significantly impacted by a faulty cylinder in the concrete pump. The cylinder's role is crucial in the concrete pumping system as it generates the necessary pressure to push the concrete through the pipes and hoses. A decrease in pumping efficiency is one of the main issues caused by a faulty cylinder. If the cylinder is worn out or damaged, it may not generate sufficient pressure to effectively push the concrete. This can lead to a decrease in the pumping rate and overall productivity of the concrete pumping operation. Moreover, a faulty cylinder can cause irregular and inconsistent flow of concrete. This can result in blockages or clogs in the pipes, disrupting the pumping process. Removing these blockages can be time-consuming and costly, as it may require disassembling the pumping system to access and clear the blocked area. Additionally, leaks can occur in the pumping system due to a faulty cylinder. These leaks not only waste concrete but also reduce the overall pressure in the system, impacting the ability to pump the concrete to the desired location. Furthermore, leaks can create a messy worksite, posing safety risks for workers and potentially damaging surrounding structures. Furthermore, the risk of equipment failure is increased by a faulty cylinder. If the cylinder malfunctions or fails completely, it can cause the entire pumping system to shut down. This can result in significant downtime and delays in the concrete pouring process, leading to additional costs and potential penalties. In conclusion, a faulty concrete pump cylinder can have a significant impact on the pumping process by reducing efficiency, causing irregular flow, promoting leaks, and increasing the risk of equipment failure. To ensure smooth and efficient concrete pumping operations, it is essential to regularly maintain, inspect, and replace the cylinder in a timely manner.

- Q: What is the purpose of a concrete pump control panel?

- The purpose of a concrete pump control panel is to provide operators with a centralized interface to control various functions and parameters of the concrete pump. This control panel allows operators to start and stop the pump, control the speed and direction of the pump, and monitor and adjust the flow and pressure of the concrete being pumped. It also provides safety features such as emergency stop buttons and alarms to protect both the operators and the equipment. Additionally, the control panel may include diagnostic features that display real-time data and alerts for maintenance and troubleshooting purposes. Overall, the purpose of a concrete pump control panel is to enhance efficiency, accuracy, and safety in the operation of the concrete pumping process.

- Q: How often should carbide wear plates be replaced in a concrete pump?

- The frequency of replacing carbide wear plates in a concrete pump depends on various factors such as the quality of the carbide, the amount of usage, and the conditions in which the pump operates. Generally, carbide wear plates may need replacement every 6 to 12 months, but regular inspection and monitoring of their condition is essential to determine the actual replacement interval.

- Q: How to judge the concrete pipeline blockage?

- Listen to the ear, there is rustling sound as normal, there is a piercing sound for the blockage

- Q: How does a concrete pump hopper grate prevent clogs?

- A concrete pump hopper grate prevents clogs by acting as a filtering mechanism. It allows only small-sized aggregates to pass through, while blocking larger debris or chunks from entering the pump system. This ensures a smooth flow of concrete, preventing any obstructions or blockages that could potentially cause damage to the pump or hinder the pumping process.

- Q: What is the function of a concrete pump remote control antenna?

- The primary role of a concrete pump remote control antenna is to establish a wireless connection between the remote control device and the concrete pump. This connection enables the operator to remotely manage various functions of the concrete pump, including initiating and terminating the pump, adjusting concrete speed and flow, and controlling boom movements. The antenna receives signals transmitted by the remote control device and transmits them to the concrete pump, enabling the operator to safely control the pump from a distance. By providing the operator with improved visibility of the pump and its surroundings, while maintaining complete operational control, this technology contributes to enhanced efficiency, accuracy, and safety at construction sites.

Send your message to us

Tungsten Carbide Zoomlion Spectacle Plate DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords