Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

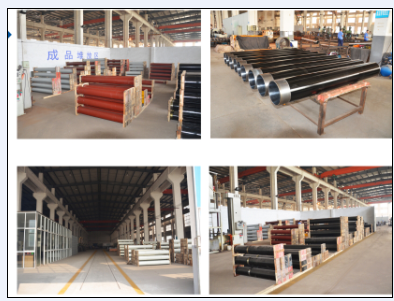

Product Description:

The Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM can only be used in Schwing concrete pumps and Schwing truck pumps construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The Cylinder is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN250*2325 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM according to customers request?

A4: Yes, we can produce Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Concrete pump spare parts may exhibit signs of wear and tear, which should not be overlooked. Some indicators include: 1. Surface damage: Cracks, dents, or scratches on pipes and hoses can signify wear and tear, particularly if they are extensive or deep. 2. Corrosion: Metal components like couplings or clamps may display signs of corrosion such as rusting or pitting, which can weaken the part and affect its functionality. 3. Leaks: Notable leaks in seals or gaskets can suggest wear and tear. Material degradation or improper installation can cause leaks, impacting the pump's efficiency and performance. 4. Decreased performance: Wear and tear in concrete pump spare parts can result in reduced overall performance. For instance, worn-out wear plates can diminish pumping capacity or increase energy consumption. 5. Heightened noise or vibrations: If noise levels or vibrations intensify while operating the concrete pump, it may indicate wear and tear in the spare parts. Imbalances, misalignments, or loose components can negatively affect the pump's performance and lifespan. 6. Excessive wear on moving parts: Moving parts like pistons or cylinders may exhibit excessive wear and tear, such as scoring or grooving on the surface. This can impede the smooth operation of the pump and potentially cause further damage if left unaddressed. Regular inspection and maintenance of concrete pump spare parts are vital to promptly identify and address any signs of wear and tear. Timely replacement or repair of worn-out components can prevent further damage, ensuring the concrete pump operates efficiently and safely.

- Q: What is the farthest pumping distance of concrete pump truck?

- Ground pump or air pump, the current delivery distance of the pump is 56, the ground pump can transport 300 meters

- Q: Are there any specific tools or equipment required for the installation of concrete pump spare parts?

- Yes, there are specific tools and equipment required for the installation of concrete pump spare parts. Some of these tools include: 1. Wrenches and sockets: These are used to loosen and tighten bolts and nuts during the installation process. 2. Hydraulic jacks: Hydraulic jacks are necessary for lifting heavy parts of the concrete pump to provide easy access for installation. 3. Crane or hoist: In cases where the parts are extremely heavy, a crane or hoist may be required to lift and position them correctly. 4. Torque wrench: This tool is essential for tightening bolts to the correct torque specifications, ensuring a secure installation. 5. Grease gun: Lubrication is important for smooth operation of moving parts, so a grease gun is used to apply grease to specific components during installation. 6. Measuring tools: Measuring tapes or rulers are necessary to ensure accurate positioning and alignment of the spare parts. 7. Safety equipment: Safety goggles, gloves, and other protective gear should be worn during the installation process to prevent injuries. It is important to note that the specific tools and equipment required may vary depending on the type and complexity of the concrete pump and its spare parts. It is always recommended to consult the manufacturer's instructions or seek professional assistance to ensure proper installation.

- Q: What is the function of a concrete pump control lever?

- The function of a concrete pump control lever is to control the flow and direction of the concrete being pumped. It allows the operator to start and stop the pump, adjust the speed of the pump, and control the placement and placement speed of the concrete. The control lever also enables the operator to switch between different pumping modes, such as pumping vertically or horizontally, and adjust the pressure of the concrete being pumped. Overall, the control lever is essential in ensuring accurate and efficient concrete pumping operations.

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- Concrete pump remote control antennas should be inspected regularly, preferably on a monthly basis, to ensure they are in good working condition. However, the frequency of replacement depends on several factors such as usage, environmental conditions, and wear and tear. It is recommended to replace the antennas if they are damaged, show signs of malfunction, or if there is a noticeable decrease in signal strength.

- Q: Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Indeed, procuring spare parts for concrete pumps equipped with various valve systems, such as S-valve or gate valve, is entirely feasible. Manufacturers and suppliers of concrete pumps generally offer an extensive selection of spare parts, which encompass valves. These spare parts can be procured either directly from the manufacturer or via authorized distributors. To ensure compatibility, it is vital to furnish precise information regarding the concrete pump model, valve type, and any other pertinent details when placing an order for spare parts. Moreover, there exist specialized firms that exclusively concentrate on providing spare parts for concrete pumps, irrespective of the valve system employed. These entities often possess a comprehensive inventory of spare parts and can offer assistance in identifying and sourcing the necessary components for your specific concrete pump.

- Q: What is the purpose of a concrete pump control panel?

- The purpose of a concrete pump control panel is to provide operators with a centralized interface to control various functions and parameters of the concrete pump. This control panel allows operators to start and stop the pump, control the speed and direction of the pump, and monitor and adjust the flow and pressure of the concrete being pumped. It also provides safety features such as emergency stop buttons and alarms to protect both the operators and the equipment. Additionally, the control panel may include diagnostic features that display real-time data and alerts for maintenance and troubleshooting purposes. Overall, the purpose of a concrete pump control panel is to enhance efficiency, accuracy, and safety in the operation of the concrete pumping process.

- Q: What are the different types of concrete pump clamps?

- There are several different types of concrete pump clamps, including snap clamps, bolt clamps, wedge clamps, and quick release clamps. These clamps are used to secure pipes and hoses in place and ensure a tight and secure connection during concrete pumping operations.

- Q: How can I determine if the concrete pump cylinder needs replacement?

- To determine if the concrete pump cylinder needs replacement, you should inspect it for any visible signs of wear or damage. Look for cracks, leaks, or excessive corrosion on the cylinder. Additionally, monitor the pump's performance and check if there are any irregularities or issues during operation, such as decreased pumping efficiency or increased noise. It is also recommended to consult with a professional concrete pump technician or manufacturer for a thorough inspection and assessment of the cylinder's condition.

- Q: Can concrete pump spare parts be coated with corrosion inhibitors for long-term storage?

- Concrete pump spare parts have the capability to be coated with corrosion inhibitors in order to ensure long-term storage. Corrosion inhibitors, which are chemicals, can be applied onto metal surfaces to either prevent or minimize the corrosion process. By administering a coating of corrosion inhibitor onto concrete pump spare parts, a protective layer can be formed, preventing any contact between moisture, oxygen, and the metal. Consequently, the chances of corrosion are significantly reduced. This becomes particularly crucial when considering long-term storage, as the spare parts might encounter harsh environmental conditions or be stored in damp areas. Ultimately, the corrosion inhibitor coating serves to extend the lifespan of the spare parts and guarantee their preservation until they are required for use.

Send your message to us

Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords