PUMPING CYLINDER(PM) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

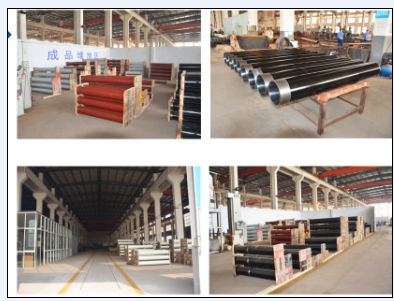

Product Description:

The Concrete Pump Delivery Cylinder DN200*1600 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN200*1600 is a concrete pumping for combined use with other concrete pumps in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder DN200*1600 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN200*1600

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN200*1600 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN200*1600 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN200*1600 ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN200*1600 according to customers request?

A4: Yes, we can produce Cylinders DN200*1600 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: Are there any safety considerations when using concrete pump spare parts?

- Concrete pump spare parts should be used with caution and with a focus on safety. High-quality parts that are compatible with the specific make and model of the pump are crucial. Using substandard or incorrect parts can lead to equipment failure, posing a danger to the operator and those nearby. Regular maintenance and inspection of the spare parts are also essential for safety. Checking for signs of wear or damage on a regular basis can help prevent accidents and equipment failure. It is vital to follow the manufacturer's guidelines for maintenance and replacement intervals. Adhering to safety procedures and protocols is a must when using concrete pump spare parts. This includes wearing appropriate personal protective equipment, such as safety goggles, gloves, and steel-toed boots. It is equally important to ensure that all operators receive proper training on equipment usage and understand the potential hazards involved. Safe operating practices are paramount when working with concrete pump spare parts. Maintaining a safe distance from the work area, ensuring the stability and security of the pump, and avoiding overloading or exceeding the recommended operating capacity are all crucial. By taking these safety considerations into account and following proper procedures, the risks associated with using concrete pump spare parts can be minimized. This ensures the safety of operators and workers on construction sites.

- Q: How often should concrete pump control panels be inspected and replaced?

- Regular inspections should be conducted on concrete pump control panels to ensure proper functioning and detect any potential problems or malfunctions. The frequency of inspections may vary based on factors such as pump type, operating conditions, and manufacturer recommendations. However, a general rule is to thoroughly inspect the panels at least once every six months or after every 500 hours of operation, whichever comes first. Trained professionals should perform these inspections, examining control panel components like buttons, switches, indicators, and wiring for signs of wear or damage. They should also test all functions and safety features to verify the panel's functionality. When it comes to replacement, it is crucial to adhere to the manufacturer's guidelines and recommendations. Typically, control panels have a lifespan of several years, but this can vary depending on factors like panel quality, frequency of use, and maintenance practices. If significant issues or failures are identified during inspections, prompt replacement of the control panel is important to ensure safe and efficient operation of the concrete pump. Ultimately, regular inspections and timely replacement of control panels are vital to minimize the risk of equipment failure, maintain safety on construction sites, and preserve the productivity and longevity of the concrete pump.

- Q: Are there any specific maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific maintenance procedures to ensure effective functioning and longevity. It is crucial to regularly maintain them. Here are some key maintenance procedures for concrete pump spare parts: 1. Lubrication: Minimize friction and wear by regularly lubricating moving parts like pistons, cylinders, and valves. This helps maintain smooth operation and prevent premature failure. 2. Cleaning: Regularly clean spare parts to remove debris, dirt, or concrete buildup. Accumulated material can hinder performance and cause damage. Use appropriate cleaning agents and tools for thorough cleaning. 3. Inspection: Routinely inspect spare parts for signs of wear, damage, or deterioration. Check for cracks, leaks, loose connections, or abnormal functioning. Promptly detect issues for timely repairs or replacements. 4. Replacement: Immediately replace worn-out or damaged spare parts. Delaying replacements can lead to further damage and costly repairs. Follow the manufacturer's recommendations for part lifespan and replacement. 5. Calibration: Correctly calibrate spare parts to maintain optimum performance. Adjust pressure settings, flow rates, and other parameters according to manufacturer's guidelines. Regular calibration ensures accurate and efficient concrete pumping. 6. Storage: Properly store spare parts to prevent damage from environmental factors. Keep them in a clean, dry place away from direct sunlight or extreme temperatures. Follow any specific storage instructions from the manufacturer. 7. Training: Train operators and maintenance personnel on proper handling, maintenance, and repair of spare parts. This ensures correct procedures are followed, minimizing damage risk and maximizing equipment lifespan. Following these maintenance procedures will keep concrete pump spare parts in optimal condition, enhancing performance, reliability, and longevity.

- Q: What is the purpose of a concrete pump hydraulic accumulator bladder?

- The purpose of a concrete pump hydraulic accumulator bladder is to store and release hydraulic energy, resulting in smoother and more efficient operation of the concrete pump.

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Yes, there are specific maintenance practices for concrete pump spare parts. Regular inspections, cleaning, and lubrication of the parts are essential to ensure their proper functioning and longevity. It is also important to follow manufacturer's guidelines and recommendations for maintenance and replacement of worn-out parts. Proper storage and handling of spare parts can also contribute to their durability and effectiveness.

- Q: Can I get spare parts for both concrete pumps with and without boom control systems?

- Yes, you can typically get spare parts for both concrete pumps with and without boom control systems. Many manufacturers and suppliers of concrete pumps offer a wide range of spare parts to meet the needs of different types of pumps. Whether it's for a pump with a boom control system or one without, you should be able to find the necessary spare parts from reputable suppliers. It is recommended to contact the manufacturer or supplier directly to inquire about the availability and compatibility of spare parts for your specific concrete pump model.

- Q: How can the concrete pump be installed and used?

- Operation should be carried out before the examination, to confirm the normal electrical equipment and instrumentation, each part of the switch button, the handle in the correct position, the mechanical part of the fastening point is firm and reliable, and the chain belt tightness to meet the requirements, the normal operation of the transmission parts

- Q: How often should concrete pump booms be inspected and maintained?

- To ensure the safe and efficient operation of concrete pump booms, it is important to inspect and maintain them regularly. The frequency of these inspections and maintenance tasks will depend on how often and under what conditions the boom is used. Generally, it is recommended to inspect and maintain the boom at least once a month or after every 250 pumping hours, whichever comes first. During these inspections, it is crucial to carefully examine the boom for any signs of wear and tear, damage, or malfunctioning parts. The hydraulic system, including the hoses, cylinders, and valves, should be thoroughly inspected and tested for leaks, blockages, or malfunctions. Additionally, the structural integrity of the boom, such as the main boom, articulation points, and outriggers, should be checked for cracks, deformations, or signs of stress. Regular maintenance of the concrete pump boom should include cleaning and lubricating all movable parts, checking and adjusting the tension of the cables, belts, and chains, and replacing any worn-out or damaged components. It is also important to inspect and test the electrical and control systems to ensure proper functioning. In addition to regular inspections and maintenance, it is crucial to follow the manufacturer's guidelines and recommendations for specific maintenance intervals and procedures. Depending on the level of usage, working conditions, and any changes in performance or operation, it may be necessary to conduct more frequent inspections and maintenance. By conducting regular inspections and maintenance, concrete pump boom owners can reduce the risk of accidents, extend the lifespan of the equipment, and ensure optimal performance. It is always advisable to consult with the manufacturer or a qualified professional to determine the most suitable inspection and maintenance schedule for a specific concrete pump boom.

- Q: How can a malfunctioning control box affect the pump's operation?

- The operation of a pump can be negatively affected by a control box that malfunctions. Initially, it can lead to an imprecise or inconsistent control of the pump's functions. This implies that the pump may not initiate or halt at the desired moments or operate at the correct velocity, resulting in ineffective or insufficient pumping. Furthermore, a control box that malfunctions can cause electrical problems, resulting in power fluctuations or even power surges. These electrical complications can harm the pump's motor or other components, leading to premature deterioration or complete malfunction. Moreover, a malfunctioning control box can also disrupt the communication between the pump and other systems. This can impact the pump's capacity to receive or transmit signals, resulting in a lack of synchronization with other equipment or systems that depend on the pump's operation. This lack of synchronization can result in system failures or interruptions in the overall process or operation that the pump supports. In conclusion, a malfunctioning control box can have adverse effects on the operation of a pump including imprecise control, electrical problems, and disruption of communication with other systems. It is essential to regularly inspect and maintain control boxes to prevent these malfunctions and ensure the reliable and efficient operation of pumps.

- Q: How can a damaged concrete pump piston affect the pumping efficiency?

- A damaged concrete pump piston can significantly affect the pumping efficiency in various ways. Firstly, a damaged piston can lead to decreased power and force exerted by the pump, resulting in reduced pumping capacity. The piston is responsible for creating the necessary pressure to push the concrete mixture through the pumping system. If it is damaged, it may not be able to generate sufficient pressure, leading to slower and less efficient pumping. Secondly, a damaged piston can cause leaks within the pump system. The piston is a critical component that seals the concrete and prevents it from leaking back into the hopper. If it is damaged or worn out, it may not create a tight seal, resulting in leakage. This not only leads to a loss of material but also reduces the efficiency of the pumping process as the pump has to work harder to compensate for the loss. Furthermore, a damaged piston can also cause blockages and clogs in the pumping system. The piston's movement creates suction, which pulls the concrete mixture into the pump. If the piston is damaged, it may not create enough suction, causing the mixture to flow unevenly or get stuck in the system. This can cause delays and interruptions in the pumping process, reducing overall efficiency. In conclusion, a damaged concrete pump piston can impact pumping efficiency by reducing power and force, causing leaks, and leading to blockages. Regular maintenance and timely repair or replacement of damaged pistons are essential to ensure optimal pumping performance and efficiency.

Send your message to us

PUMPING CYLINDER(PM) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords