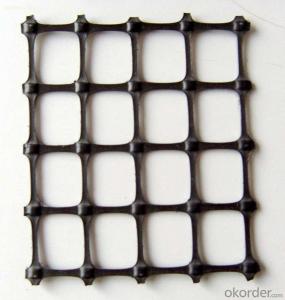

Protection Geogrids applied in all kinds of roads,airports to enhance the roadbed

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Porducts Description

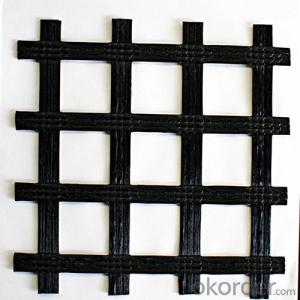

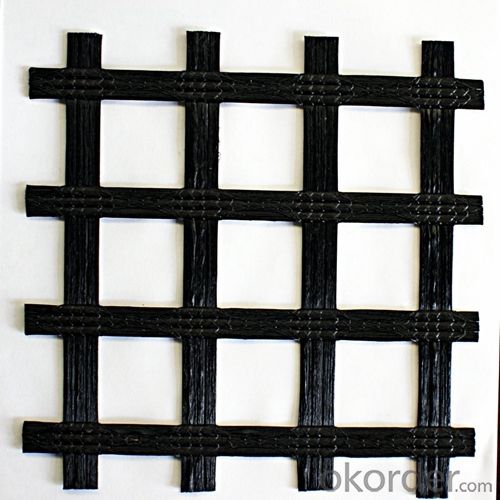

PET geogrid

15X15,20X20,25X25,30X30,35X35,40X40,50X50,60X60.

70X70,80X80,90X90,100X100,110X110KN

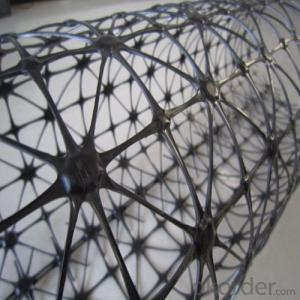

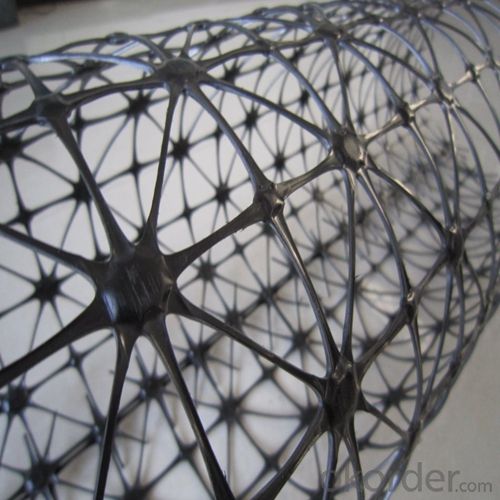

steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Slopes and subgrades with rails are a serious problem in railroad construction. Under high pressure the layers slide and deform consequently causing rail deformation, which requires closing railroad segments for a long time. Geogrid application allows carrying out comlex repair operations of the necessary road segment in shortest time (which is very essential in transportation).

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

fiberglass geogrid/glass fiber geogrid with CE certificateIntroduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: 300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q: What are the different factors that affect the performance of geotextiles?

- There are several factors that can affect the performance of geotextiles. These include the type and quality of the materials used, the design and construction of the geotextile, the installation and maintenance practices, the environmental conditions such as temperature and moisture, and the load and stress applied to the geotextile. Additionally, factors such as chemical exposure, biological activity, and aging can also impact the performance of geotextiles.

- Q: What are the specifications for geotextiles in pond liner projects?

- The specifications for geotextiles in pond liner projects typically include factors such as weight, tensile strength, permeability, and puncture resistance. The geotextile should be heavy enough to provide sufficient protection against punctures and tears, while also allowing for water to pass through and prevent buildup on the liner. It should have high tensile strength to withstand the stresses of installation and long-term use. Additionally, the geotextile should meet industry standards and regulations for quality and durability in pond liner applications.

- Q: Can geotextiles be used in pond liners?

- Yes, geotextiles can be used in pond liners. Geotextiles are often used as a protective layer in pond liners to provide additional strength, durability, and resistance to punctures or tears. They help prevent the migration of soil particles and provide stability to the liner, making them a suitable choice for pond construction.

- Q: Can geotextiles be used in foundation drainage systems?

- Yes, geotextiles can be used in foundation drainage systems. Geotextiles are commonly used as a filter and separator in drainage systems to prevent soil migration and clogging of drainage pipes. They help to improve the efficiency and longevity of foundation drainage systems by allowing water to flow freely while keeping the soil particles in place.

- Q: Where is the geotextile in the municipal works?

- Conservation, consideration, there is more green and more Chinese geotextile material manufacturers

- Q: Are geotextiles suitable for use in geotextile-reinforced soil walls?

- Yes, geotextiles are suitable for use in geotextile-reinforced soil walls. Geotextiles are designed to provide reinforcement, filtration, and separation functions in various geotechnical applications, including soil walls. They help to enhance the stability and strength of the soil structure, prevent soil erosion, and improve drainage. Geotextiles also offer durability and resistance to biological degradation, making them a reliable choice for geotextile-reinforced soil walls.

- Q: What are the key considerations for geotextile installation in cold climates?

- Some key considerations for geotextile installation in cold climates include selecting a geotextile material that is designed for cold weather conditions, ensuring proper site preparation and ground stabilization, protecting the geotextile from frost heave or ice damage, and taking into account the potential for snow accumulation and removal on the geotextile surface. Additionally, considering the impact of freeze-thaw cycles and designing proper drainage systems are crucial for successful geotextile installation in cold climates.

- Q: What does geotextile 200g mean? A total of so many shops, or how many square meters shop so much ah

- Geotextile 200g is a geotextile specification 200g / m2

- Q: What are the applications of geotextiles?

- Geotextiles have a wide range of applications in civil engineering and environmental projects. They are commonly used in road construction, where they provide stability, erosion control, and reinforcement. Geotextiles are also utilized in landfills to separate and protect soil layers, preventing contamination. Additionally, they are employed in coastal engineering to mitigate erosion and stabilize shorelines. Geotextiles are also used in drainage systems, agriculture, and landscaping to control erosion, filter water, and promote vegetation growth.

Send your message to us

Protection Geogrids applied in all kinds of roads,airports to enhance the roadbed

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords