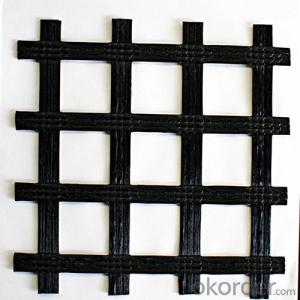

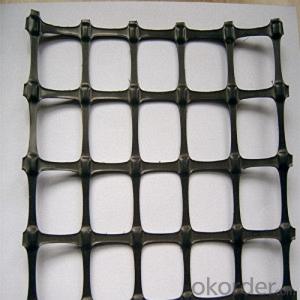

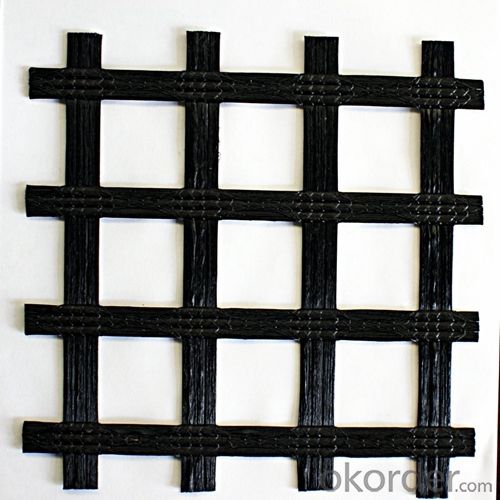

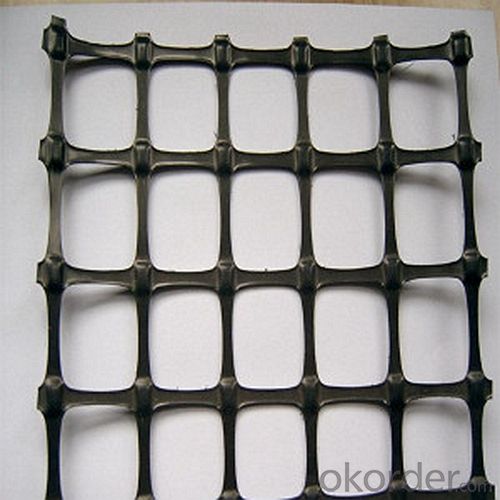

Geotextile Paper Fiberglass Geogrid for Roadbed Reinforcement in Highway, Railway, and Municipal Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

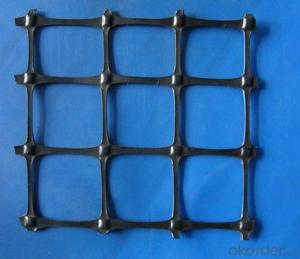

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Model Number:

EGA50-50, EGA80-80, EGA100-100

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Fiberglass Geogrid Application

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering applications for their ability to provide stability, filtration, and separation. When placed correctly, geotextiles can enhance the strength and durability of bridge abutments by distributing load, preventing soil erosion, and improving overall stability.

- Q: Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q: Can geotextiles be used in mine tailings dam construction?

- Yes, geotextiles can be used in mine tailings dam construction. Geotextiles are commonly used as a geosynthetic material in various civil engineering applications, including dam construction. In the case of mine tailings dam construction, geotextiles can provide reinforcement, filtration, and drainage properties to enhance the stability and performance of the dam. They can help prevent soil erosion, control water flow, and improve the overall integrity of the structure.

- Q: Can geotextiles be used for reinforcement in embankment construction?

- Yes, geotextiles can be used for reinforcement in embankment construction. Geotextiles are often used to improve the stability and strength of embankments by distributing loads and reducing the risk of soil erosion. They provide additional support to the soil, preventing settlement and enhancing the overall performance of the embankment.

- Q: Geotextile vertical and horizontal stretching the gap is too much how to adjust

- Geotextile longitudinal and horizontal tensile strength of the gap adjustment, mainly in the carding, laying the net, drawing three links to control, sort out the ratio of Daofu regulation, shop layer, shop curtain speed ratio, Sticks, input and output differences, and so are the cause of a huge gap, the other fiber curl, and so is the key. For the above adjustment, you will find the law. In order to geotextile stretch the vertical and horizontal adjustment equal.

- Q: How do geotextiles affect soil moisture retention?

- Geotextiles can significantly impact soil moisture retention by acting as a barrier between the soil and the external environment. They help in reducing excessive evaporation from the soil surface, thus minimizing water loss. Additionally, geotextiles prevent the erosion of soil particles, maintaining soil structure and facilitating better water infiltration. This ultimately improves soil moisture retention by creating a more favorable and stable environment for plants to grow.

- Q: Can geotextiles be used in agricultural applications?

- Yes, geotextiles can be used in agricultural applications. They are commonly used to control soil erosion, improve soil stability, and enhance drainage in agricultural fields. Geotextiles can also be used for weed control, separating different soil layers, and protecting plants from pests and harsh weather conditions.

- Q: Can geotextiles be used in bridge abutment reinforcement?

- Yes, geotextiles can be used in bridge abutment reinforcement. Geotextiles are commonly used in civil engineering projects, including bridge construction, to improve soil stability, prevent erosion, and provide additional reinforcement. They can be installed behind the abutment walls or embankments to distribute loads, reduce settlement, and increase the overall stability and durability of the structure.

- Q: What are the different geotextile weight classes and their applications?

- Geotextiles are categorized into different weight classes based on their mass per unit area. These weight classes range from lightweight to heavyweight. Lightweight geotextiles, usually less than 200 grams per square meter (gsm), are commonly used in erosion control applications, such as slope stabilization and vegetation support. They provide filtration and separation functions while allowing water to pass through. Medium-weight geotextiles, typically ranging from 200 to 400 gsm, are often employed in applications like road stabilization, embankment reinforcement, and subgrade separation. They offer a balance between strength and permeability, ensuring proper drainage and preventing soil movement. Heavyweight geotextiles, exceeding 400 gsm, are primarily used in applications requiring high strength and durability. These include shoreline protection, coastal engineering, and land reclamation projects. They provide robust reinforcement and act as a barrier against erosion and wave action. The choice of geotextile weight class depends on the specific engineering requirements of the project, such as soil conditions, anticipated loads, and desired drainage characteristics.

- Q: How are geotextiles secured in place?

- Geotextiles are typically secured in place using various methods such as anchoring pins, stakes, or other mechanical devices that are driven into the ground. Additionally, they can also be secured using soil cover, rocks, or other heavy materials to prevent them from shifting or moving.

Send your message to us

Geotextile Paper Fiberglass Geogrid for Roadbed Reinforcement in Highway, Railway, and Municipal Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords