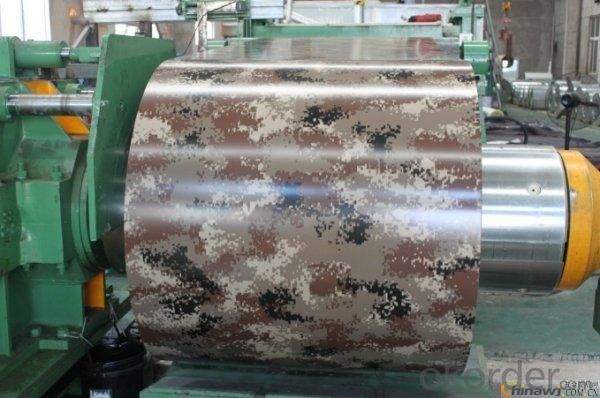

Printing Steel for Decoration JIS 3312 CGCC ASTM A653

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Printing steel plate is the product based on the metal sheet, of which surface is finally installed of the plastic film(PVC,PE) in addition to being firstly covered with the coating and printed ink in. The coated layer of printing steel olate consists of chemical and filming layer, primer coated layer, pattern printed lay and surface coated layer.The top and back coating shall generally be the application of the weatherproof paint, as well can be application of the paint with special capabilities.

Main Features

Long term usage

Corrosion resistant

Images

Specification

Base Material: HDGI ALUZINC CR

Grade: SGCC,DX51D,ASTMA653

Thickness: 0.3-0.8 TMT

Width 600-1450mm

Zinc Coating: 60-185g/m2

Paint: PE,PVDF,SMP,HDP

Coil ID:

508/610 recommend 508

Coil Weight: 4-8mt

T BENDING: 0-3T

PENCIL HARDNESS: ≥2H

IMPACT: ≥9J

MEK: ≥100

SALT SPRAY: ≥720hr

FAQ

Standard export packing, 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk, galvanized metal and waterproof paper around circumference and bore protection

- Q: What are the different types of steel coil packaging techniques?

- There are several types of steel coil packaging techniques, including banding, strapping, shrink wrapping, and palletizing. Banding involves securing the coil with metal bands, while strapping uses plastic or steel straps. Shrink wrapping involves wrapping the coil with plastic film and applying heat to shrink it tightly. Palletizing involves stacking the coils on a pallet and securing them with stretch wrap or straps. These techniques help protect the coils during transportation and storage.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It needs to be RED hot, the hotter the better. Yes you can use a camp fire if you put the file directly in the hottest part of the coals, but it'll take about 5-10 minutes to heat. Charcoal briquettes would probably work better as a heat source. You can use something like a blow dryer to intensify the coals, that might help. You'll also need a bench vice, and the biggest pair of pliers you can find, for leverage. Bending steel's not easy even when it's hot. You could also use a bit of steel pipe that'll fit over the end of the file. Stick the file in the vise when red-hot, slip the pipe over the free end, and use the pipe to bend it. OR, you could use the old-fashioned method of just holding it with pliers in one hand, and hitting it with a 5lb sledge hammer with the other. use something solid as an anvil, like a large steel pipe. you mighe be able to get away with using a small log, but you'll have to work twice as hard. Safety glasses are MANDITORY for this type of thing. Do not attempt without eye protection at all times. Ear plugs are also a very good idea.

- Q: How are steel coils used in the manufacturing of packaging materials?

- Steel coils are used in the manufacturing of packaging materials as they provide strength and stability to the packaging structure. They are commonly used as a core material for packaging tubes, enabling them to withstand heavy loads and prevent deformation. Additionally, steel coils are utilized in the production of steel straps, which are widely used for securing packages and pallets, ensuring safe transportation and storage of goods.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- Traditionally woks do take a long to heat up but the trick is that they hold the heat for a long time, so either stainless steel for convenience or cast iron for tradition. Don't use anything non stick, chinese cooking uses a lot of oil, the non-stick will just be unhealthy when it starts to burn off. The cast iron will be good because it'll heat up and keep its heat, in chinese homes that have the wok, the wok usually gets heated up throughout a few hours, you need it to be really hot all the way through all over the pan to do chinese cooking. also traditionally woks are built into home or are big and positiioned over a fire not to be moved too much, the point is to keep stiring and stiring and stiring until your food is cooked.

- Q: I'm kind of confused as to how the difference between a stainless steel and blued steel firearm is sometimes only $20 or so. Isn't stainless steel fairly more expensive to manufacture than plain carbon steel? Are some stainless steel firearms simply stainless steel finished with carbon steel underneath?

- No, there are no rifles produced that are carbon steel underneath with a stainless steel finish. Typically, gun prices are set by whatever people will pay for the finished product, NOT based on what the material costs actually are. Even if the stainless were CHEAPER to produce, manufacturers could still charge a premium on those products because it offers an advantage to the user (less maintenance). Stainless is seen as an upgrade because of the maintenance and the good looks, so it's like an upgrade option on a sports car, even if it doesn't improve actual performance, it improves the marketability for the product, so it increases the product price. For rifle barrels, many manufactures do NOT charge a high mark up for stainless steel because even though YES is is harder to machine, they don't have to blue the part, which is an extra processing step, and extra materials cost. So when a stainless steel blank is made, it is machined, washed, and finished, but a chrome-moly barrel much be machined, washed, prep'd, hot blued, and finished.

- Q: is it much difference between 1095 and 1080,,,1065,,,1060 or even 1045 steel?please help and thanks!

- Carbon Steel Swords

- Q: I'm analysing horse stirrups and would like to know the disadvantages to stainless steel? - thanks

- For horse stirrups the main disadvantage to stainless steel is the manufacturing cost. Stainless steels tend to work harden, and are subject to their own peculiar forms of corrosion, but I see little implication to either of these factors when used as a stirrup iron or a safety latch. Stainless steel is also subject to self welding, or galling, this would be of no concern for the irons, but could result in the pivot of the safety latch freezing (I have never known anyone to ride with the safety latch closed, however).

- Q: What are the common thickness tolerances for steel coils?

- The common thickness tolerances for steel coils usually range from +/- 0.001 to +/- 0.005 inches, depending on the specific industry standards and customer requirements.

- Q: How are steel coils used in the production of metal bridges?

- Steel coils are used in the production of metal bridges as they are rolled into the desired shape and size to form the structural components of the bridge, such as beams, girders, and support structures. These coils provide the necessary strength and durability to withstand the weight and stress of the bridge, ensuring its long-term stability and safety.

- Q: What are the common coil coating materials?

- The common coil coating materials include polyester, polyurethane, polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP).

Send your message to us

Printing Steel for Decoration JIS 3312 CGCC ASTM A653

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords