prepainted steel coil JIS G 3312

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

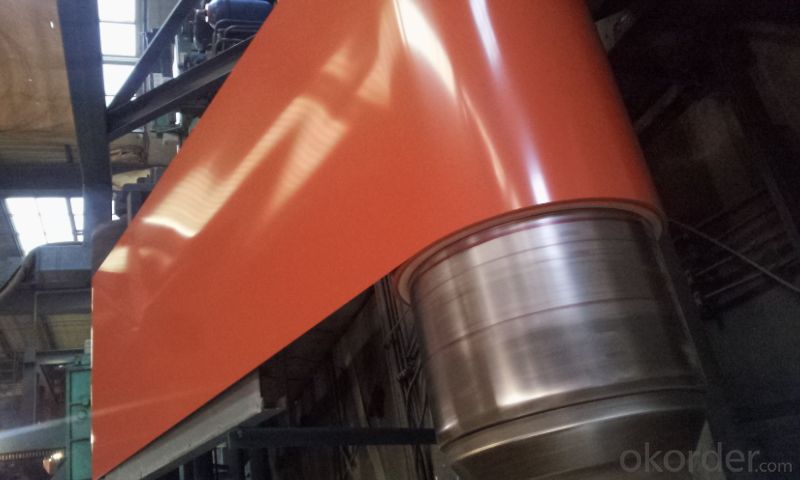

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

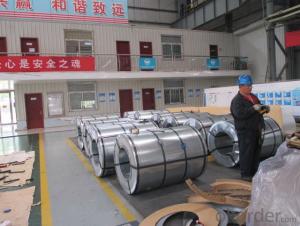

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: What are the factors that affect the electrical conductivity of steel strips?

- The factors that affect the electrical conductivity of steel strips include the composition of the steel, impurities present, temperature, and the presence of any protective coatings.

- Q: How are steel strips used in the manufacturing of agricultural machinery?

- Steel strips are commonly used in the manufacturing of agricultural machinery for various purposes such as reinforcement, structural support, and forming essential components like blades, frames, and chassis. The high tensile strength and durability of steel strips make them ideal for withstanding the demanding conditions and heavy loads experienced in agricultural operations. Additionally, steel strips can be easily shaped and welded, allowing manufacturers to customize and assemble the machinery efficiently.

- Q: How are steel strips used in the production of automotive fasteners?

- Automotive fasteners rely heavily on steel strips, an essential component for their production. These strips are typically crafted from top-notch steel, known for its exceptional strength, durability, and resistance to corrosion. The primary purpose of steel strips in automotive fastener production is to shape the fastener bodies themselves. After being cut into specific widths and lengths, the strips undergo various processes such as stamping, bending, and rolling to achieve the desired fastener design. This meticulous approach ensures that the fasteners possess the necessary structural integrity to effectively perform their intended function. Furthermore, steel strips are also utilized to create threads on the fasteners. Through rolling or cold-forming, these strips fashion threads with precise dimensions and profiles. These threads play a pivotal role in securely fastening components together, enabling easy insertion and tightening of the fastener. In addition, steel strips often undergo coating or treatment to enhance their performance in automotive applications. For instance, they can be coated with materials like zinc, chrome, or other corrosion-resistant substances to safeguard the fasteners against rust and other forms of deterioration. This becomes particularly crucial in the automotive industry, where vehicles face exposure to various environmental factors such as moisture, salt, and chemicals. To summarize, steel strips hold immense significance in the realm of automotive fastener production. They contribute to forming fastener bodies, creating threads, and providing corrosion resistance. By employing high-quality steel strips, automotive fasteners can meet the industry's rigorous requirements in terms of strength, durability, and longevity.

- Q: What is the difference between galvanized and zinc-coated steel strips?

- Galvanized steel strips and zinc-coated steel strips are frequently used interchangeably, but there exists a subtle distinction between the two. Both types of steel strips possess a zinc layer that safeguards the underlying steel against corrosion. Galvanized steel strips feature a pure zinc layer, which is achieved through either a hot-dip galvanizing process or electroplating. This generates a thick and long-lasting zinc layer that offers exceptional resistance against corrosion. Galvanized steel strips find widespread use in outdoor settings or environments with high humidity or exposure to corrosive elements. In contrast, zinc-coated steel strips are coated with a zinc alloy layer, typically a combination of zinc and other elements like aluminum or magnesium. This alloy coating provides improved resistance against corrosion compared to pure zinc, making it suitable for more demanding applications. Zinc-coated steel strips are commonly employed in industries such as automotive, construction, and manufacturing, where durability and corrosion resistance are paramount. To summarize, although both galvanized and zinc-coated steel strips provide corrosion protection, the distinction lies in the composition of the coating. Galvanized steel strips possess a pure zinc coating, while zinc-coated steel strips have a zinc alloy coating. The choice between the two depends on the specific application and the desired level of corrosion resistance.

- Q: How are steel strips used in the manufacturing of air conditioning systems?

- Air conditioning systems utilize steel strips in various ways during the manufacturing process. To begin with, they are commonly employed in constructing the system's outer casing, which provides a robust and long-lasting structure. Steel strips are renowned for their exceptional strength and resistance to corrosion, making them an ideal material for this purpose. Furthermore, steel strips are utilized to fabricate the different components and parts within the air conditioning system. These can encompass heat exchangers, condenser coils, evaporator coils, and fan blades, among others. Steel strips are shaped, cut, and formed into desired shapes and sizes to create these components. They are chosen due to their ability to withstand high temperatures, pressure, and exposure to refrigerants, ensuring the system's longevity and efficiency. Additionally, steel strips also find application in the manufacturing of air conditioning ductwork. Ductwork is an integral part of the system that facilitates the distribution of conditioned air throughout a building. Steel strips are employed in creating the ducts, guaranteeing their rigidity and stability. This aids in maintaining airflow and preventing any leaks or inefficiencies within the system. In conclusion, steel strips perform a vital role in the manufacturing of air conditioning systems. They are employed in constructing the outer casing, fabricating various components, and manufacturing ductwork. The utilization of steel strips ensures the durability, efficiency, and longevity of the air conditioning system, making them an indispensable material in this industry.

- Q: How are steel strips tested for flatness?

- Various techniques are employed to test the flatness of steel strips. One commonly used method is the optical flatness measurement method, which involves positioning a light source beneath the strip and a camera above it. When the light passes through the strip, any deviations in flatness cause the light to scatter or reflect differently, which is then captured by the camera. This captured image is subsequently analyzed using specialized software to measure the variations in flatness across the strip. Another method utilized is the straight edge method, where a straight edge is placed along the strip's length. Any gaps or light visible between the strip and the straight edge indicate areas of non-flatness. This method is relatively simple and can be conducted manually. Laser sensors are also employed to measure flatness. These sensors emit a laser beam that scans across the strip's surface. As the laser beam encounters irregularities or deviations in flatness, it reflects back differently. The sensor detects these reflections and converts them into measurements of flatness. In addition, some manufacturers employ the roller leveler method. This method involves passing the steel strip through a series of rollers that apply pressure to flatten it. The amount of pressure applied and the resulting changes in strip thickness are measured to determine flatness. Overall, these diverse testing methods enable manufacturers to ensure the flatness of steel strips, a critical requirement in industries such as automotive, aerospace, and construction where precise flatness is essential.

- Q: Are steel strips suitable for making electrical transformers?

- Yes, steel strips are suitable for making electrical transformers. Steel is commonly used in transformer construction due to its high magnetic permeability and low electrical resistance. Steel strips provide a compact and efficient design for the transformer core, allowing for the effective transfer of electrical energy between the primary and secondary windings. Additionally, steel strips are durable and provide good mechanical strength, ensuring the longevity of the transformer. Therefore, steel strips are a suitable choice for making electrical transformers.

- Q: How are steel strips used in the production of kitchen utensils?

- Kitchen utensils utilize steel strips in various ways during production. Firstly, these strips serve as the primary material for the utensils. Steel is renowned for its robustness and endurance, making it an exceptional choice for utensils that must endure frequent usage and exposure to heat and moisture. The strips undergo cutting, shaping, and forming processes to create diverse utensil shapes, such as spoons, forks, and spatulas. Furthermore, steel strips find application in manufacturing the handles of kitchen utensils. These strips are bent, molded, and affixed to the main body of the utensil to provide users with a comfortable and sturdy grip. To enhance grip and prevent slipping, the steel handles are often coated with materials like rubber or plastic. Additionally, steel strips are utilized for producing cutting utensils like knives. These strips are sharpened to form the blade, which is then attached to a handle. The steel used for knife blades undergoes hardening and tempering processes to ensure sharpness and longevity. To sum up, steel strips play a vital role in the production of kitchen utensils. They provide the necessary strength and durability for utensils to withstand daily use and can be shaped into various designs. Whether used as the base material, for handles, or for blades, steel strips are an indispensable component in the manufacturing process of kitchen utensils.

- Q: Can steel strips be used for making precision components?

- Yes, steel strips can be used for making precision components. Steel strips provide excellent strength, durability, and dimensional stability, making them suitable for manufacturing precision components that require tight tolerances and high precision. Additionally, steel strips can be easily machined, formed, and heat-treated to achieve the desired specifications, making them a versatile choice for precision component production.

- Q: Can steel strips be used for making precision machined parts?

- Indeed, precision machined parts can be crafted using steel strips. The durability and strength of steel strips make them highly sought after in diverse industries. By machining them with exact dimensions and tolerances, precision components can be efficiently produced. With their exceptional mechanical properties, like high tensile strength and hardness, steel strips guarantee the dependability and longevity of machined parts. Moreover, the availability of various grades and finishes enables customization to meet specific demands. Ultimately, steel strips emerge as a trustworthy option for manufacturing precision machined parts.

Send your message to us

prepainted steel coil JIS G 3312

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords