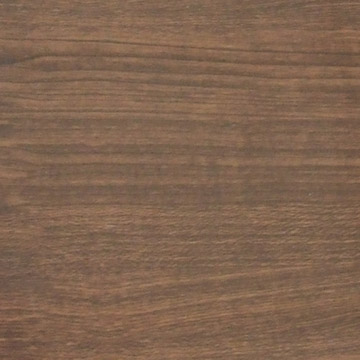

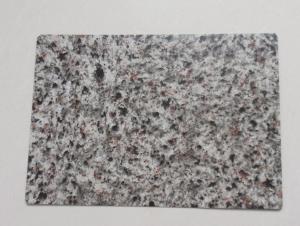

Pre-painted Galvanized Steel Coil-JIS G 3312-wooden pattern6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: What are the different types of steel coil packaging machines?

- There exists a variety of steel coil packaging machines in the market, each serving a specific purpose. These machines are designed to package steel coils efficiently and effectively for storage, transportation, or distribution. Some of the available types of steel coil packaging machines are as follows: 1. Fully automated steel coil packaging machine: This machine is equipped with advanced technology and can handle large-scale packaging requirements. It wraps the steel coils with a protective layer of film or paper and can also apply strapping or stretch film to secure the coils during transportation. 2. Semi-automated steel coil packaging machine: This machine requires some manual intervention for loading and unloading the steel coils. It is suitable for medium to high-volume packaging needs and strikes a good balance between automation and cost-effectiveness. The machine typically employs a combination of wrapping, strapping, and shrinking techniques to package the coils. 3. Steel coil packaging machine with a vertical design: This machine is specifically designed for packaging vertical steel coils. It wraps the coils with a layer of film or paper and then applies strapping or stretch film to secure them. The vertical design facilitates easy loading and unloading of the coils. 4. Steel coil packaging machine with a horizontal design: This machine is ideal for packaging horizontal steel coils. It wraps the coils with a protective layer of film or paper and then applies strapping or stretch film to secure them. The horizontal design ensures convenient loading and unloading of the coils. 5. Customized steel coil packaging machine: Certain manufacturers offer customized packaging solutions tailored to specific requirements. These machines can be adjusted to accommodate different coil sizes, shapes, and packaging materials. They are designed to provide utmost flexibility and efficiency in the packaging process. To summarize, the different types of steel coil packaging machines encompass fully automated, semi-automated, vertical, horizontal, and customized machines. The selection of a suitable machine depends on factors such as packaging volume, coil orientation, and specific requirements of the steel coils being packaged.

- Q: How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery primarily for the construction of structural components such as frames, supports, and rollers. The high tensile strength and durability of steel coils make them ideal for handling heavy loads and ensuring the stability and longevity of packaging machinery during operation.

- Q: I have one and wonder how much force this can take since it does seem like you can bend it(Sure it's impossible with hands), but I don't want to try that cause i don't want to break it. Many people say that it's really hard and can handle a hammer smash? is that true and can it even make it through more force. Cause steel is harder than iron and iron is pretty hard... So how much can i trust this locks security, i mean if i put at at a door would some thiefes be able to break it, if they had the right tools??

- any pair of larger bolt cutters would whack right thru that lock brother. use it, but put a backup lock on somewhere else too. thx for the pic!

- Q: Looking for a new entry door for my home If someone would explain the features and benefits of both fiberglass and steel doors I would greatly appreciate it!!

- price and weight. fiberglas is better but more $

- Q: Im in the process of replacing the gutters/down spouts on my house. The top of the house is four sided. The bottom level has a porch area with 3 sides, two smaller roofs in the back, and one small roof on the side with all stainless steel gutters. A two story house. Not sure of the demensions. They were made at a Steel Mill where the previous owner, worked.This guy wants to buy the stainless gutters but I need to know the market value of this steel and offer him a price. Can someone tell me what I can sell it for? Does it go by the pound? Foot? Can you give me an idea please? Theres a lot of it! I have no clue what to do! Thanks!

- i know it goes buy the pound but i do not know how mutch a pound.waite for some more answers someone must know.or call your local junk yard and ask them.

- Q: Is 440 steel relatively strong or weak?

- medium-strong....you probably mean Steel 44... right?

- Q: What are the different types of steel alloys used in coil production?

- There are various types of steel alloys used in coil production, including carbon steel, stainless steel, galvanized steel, and electrical steel. Each alloy has its own unique properties and composition, making them suitable for different applications in the manufacturing industry.

- Q: What is the shelf life of steel coils?

- Various factors, such as the type of steel, its specific application, and the storage conditions, can affect the shelf life of steel coils. Generally, steel coils have a lengthy shelf life due to their durability and resistance to corrosion. When stored correctly in a dry and controlled environment, steel coils can maintain their quality for many years. It is important to consider that certain types of steel, like galvanized steel, may have a shorter shelf life if the protective coating is compromised and corrosion occurs. Additionally, exposure to extreme weather conditions, high humidity, or chemicals can reduce the shelf life of steel coils. To ensure the longevity of steel coils, it is advisable to store them in a covered area to protect them from moisture and direct sunlight. Proper stacking and handling techniques should also be employed to prevent any damage that could lead to premature deterioration. In conclusion, the shelf life of steel coils can vary, but with appropriate storage and handling, they can remain in good condition for an extended period. This makes them a reliable and long-lasting material for various applications.

- Q: What are the different grades of steel used for manufacturing coils?

- The different grades of steel used for manufacturing coils include low carbon steel, medium carbon steel, high carbon steel, and stainless steel.

- Q: How are steel coils used in the manufacturing of construction bulldozers?

- Steel coils are used in the manufacturing of construction bulldozers as they provide the necessary strength and durability required for the heavy-duty components of the machine. These coils are typically shaped and welded to form the structural frame, blades, and bucket of the bulldozer, ensuring that it can withstand the rigorous demands of construction and earthmoving tasks.

Send your message to us

Pre-painted Galvanized Steel Coil-JIS G 3312-wooden pattern6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords