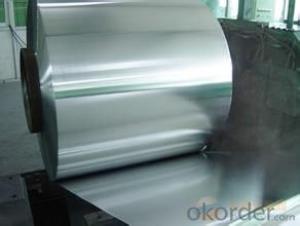

cold rolled steel coil / sheet / plate -SPCG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Images:

Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: Can you use regular welding rods when welding stainless steel?Thank you.

- Yes you can use regular welding rods for stainless steel. But you will not have the properties of the stainless. The weld joint will have a different color than the stainless if you grind/grain/finish the weld. It could also rust. The joint could be weaker. It is best to use a rod that comes as close to the base metal stainless as possible. (30 years welding - certified)

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core material for transformers and motors. The coils are wound around an iron core to create electromagnetic fields that enable efficient energy transfer and power generation within these appliances.

- Q: What is the difference between galvanized and galvalume steel coils?

- Both galvanized and galvalume steel coils have undergone a coating process to enhance their durability and resistance to corrosion. However, there are distinct differences between the two. Galvanized steel coils have a layer of zinc coating, which provides excellent corrosion resistance and protects the underlying steel from rust and other forms of deterioration. The zinc coating also acts as a barrier against moisture and prevents direct contact between the steel and the elements. Galvanized steel coils are commonly used in construction, automotive manufacturing, and agricultural equipment, where corrosion resistance is crucial. On the other hand, galvalume steel coils are coated with a combination of zinc and aluminum. This unique coating composition offers enhanced corrosion resistance compared to galvanized steel coils. The aluminum in the coating acts as a sacrificial anode, providing additional protection to the steel by sacrificially corroding instead. This sacrificial protection mechanism helps the underlying steel remain intact and prevents the spread of corrosion even if the coating is damaged. Galvalume steel coils are often used in environments with extreme weather conditions and high humidity, making them suitable for roofing, siding, and other outdoor applications. To summarize, the main difference between galvanized and galvalume steel coils lies in the composition of their coatings. Galvanized steel has a zinc coating, while galvalume steel has a combination of zinc and aluminum. Galvalume steel offers superior corrosion resistance due to the sacrificial protection provided by the aluminum in the coating. The choice between the two depends on the specific application and the level of corrosion resistance required.

- Q: When i was 15 i got caught steeling at Super A yes i know i cant believe it. They didnt call the cops or anything they released me to my aunt they took my name and adress and everythimg they said it wouldnt be on my record. But I'm not so sure. Will it be on my record if they didn't call the cops?i live in california. Is there any way i can check my record?

- Steeling? What's that? Did you take a piece of steel and weld it? I am confused?

- Q: Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. Steel coils are often processed into various shapes and forms, such as beams, columns, or plates, to provide structural support and strength in construction projects. The use of steel coils ensures durability, load-bearing capacity, and resistance to deformation, making them suitable for structural applications in buildings, bridges, and other infrastructure projects.

- Q: How are steel coils inspected for straightness using laser alignment?

- The straightness of steel coils is examined using laser alignment technology in a precise and automated manner. This technology offers a non-contact approach to measuring the straightness of steel coils with high accuracy and efficiency. To begin with, a conveyor system is utilized to move the steel coil through the inspection area. As the coil passes through, a laser alignment system is set up to emit a laser beam across the width of the coil. This laser beam acts as a reference line for measuring straightness. The laser alignment system consists of a laser emitter and a receiver unit. The emitter projects a perfectly straight and parallel laser beam for alignment purposes. On the opposite side of the coil, the receiver unit captures the laser beam and analyzes its position. As the coil progresses through the inspection area, the receiver unit determines the deviation of the laser beam from the desired straight line. This is accomplished by analyzing the position of the laser beam at multiple points along the width of the coil. The laser alignment system is connected to a computerized control system that processes the data obtained from the receiver unit. The control system performs intricate calculations to determine the straightness of the coil based on the position of the laser beam. Any variations or deviations from the desired straight line are recorded and thoroughly examined by the control system. The inspection data can be viewed in real-time, enabling operators to monitor the straightness of the steel coil during the inspection process. The use of laser alignment technology for steel coil inspection offers numerous benefits. It provides highly precise measurements, ensuring that even slight deviations from straightness are detected. Furthermore, the non-contact nature of laser alignment eliminates the need for physical contact with the coil, thus reducing the risk of damage or contamination. Additionally, the automated process saves time and enhances efficiency compared to manual inspection methods. In conclusion, laser alignment technology is a dependable and efficient method for inspecting the straightness of steel coils. It guarantees that only coils meeting the required straightness criteria are approved, thereby contributing to the quality control of steel manufacturing processes.

- Q: I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- If you want steelix is good as he can use fire and steel.

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are used in the manufacturing of metal structures as they are shaped and formed into various components such as beams, columns, and plates. These coils are unrolled and processed through machines that cut, shape, and weld them together to create the desired structure. The strength and durability of steel make it an ideal material for constructing buildings, bridges, and other metal structures.

- Q: How are steel coils used in the automotive stamping process?

- Steel coils are used in the automotive stamping process as they are unrolled and fed into stamping machines, where they are shaped and cut into various automotive parts such as body panels, chassis components, and engine parts.

- Q: What is the role of steel coils in the electrical industry?

- The role of steel coils in the electrical industry is significant as they serve multiple purposes in various applications. Steel coils are used as components in transformers, which are essential for power distribution and voltage regulation. These coils are responsible for transferring electrical energy from one circuit to another, allowing for efficient transmission of electricity across long distances. Additionally, steel coils are utilized in the production of electric motors and generators. They are wound around the stator and rotor to create magnetic fields, which enable the conversion of electrical energy into mechanical energy and vice versa. This process is crucial in various industries, including automotive, manufacturing, and renewable energy sectors. Steel coils also play a role in the production of electrical cables and wiring. They are used to provide strength, durability, and protection to the conductive copper or aluminum wires within the cables. These coils are responsible for maintaining the structural integrity of the cables, ensuring safe and efficient transmission of electricity. Furthermore, steel coils find application in electrical equipment such as solenoids and relays, where they help create magnetic fields to control the flow of electrical current. They are also used in various electrical appliances, including refrigerators, air conditioners, and televisions, where they act as essential components in the functioning of these devices. In summary, steel coils have a vital role in the electrical industry. They are used in transformers, motors, generators, cables, and various electrical equipment, contributing to the efficient distribution, conversion, and transmission of electrical energy.

Send your message to us

cold rolled steel coil / sheet / plate -SPCG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords