PREPAINTED STEEL COIL STANDARD JIS G 3312 CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

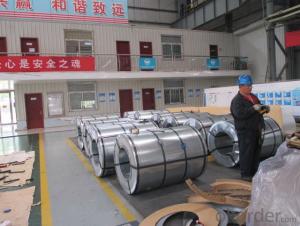

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package: Properly packed for ocean freight exportation in 20''container

Application:: home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: I noticed a friend's appliances are not magnetic, and mine are. Both are stainless steel. Are there two types of stainless steel or something? Thanks

- Some stainless steel are magnetic and some aren't. The real high grade stainless steels aren't magnetic.Stainless is just regular steel with varying degrees of nickel and chromium alloys mixed in the batch. The more nickel and chromium the less likely to be magnetic. A lot of stainless exhaust pipes and barbecue grills claim to be stainless, and yet they still rust and tend to be magnetic. They must use the bare minimum of nickel and chromium in the melted batch just to claim the title of stainless steel. Nickel and chromium are quite expensive and they are what gives the steel the anti-corrosion and extreme hardness characteristics along with loss of magnetism of the steel. If you have stainless steel that is magnetic , it is a good sign it is stainless steel that barely meets the criteria of true stainless steel.

- Q: Hi, I live in the Boston area and I'm trying to find a steel suppler that can provide mild steel for hobby welding. I can go through my job, but we only put in orders every couple of months so it's not very convenient. Also, the few suppliers I've found only sell in bulk. So if anyone knows where I can angle irons, flat bars, sheets, etc... by the piece it would greatly appreciated. Thanks

- They will sell any quantity of metal and even cut it to size - my experience has been that their prices are not wildly out of line for single pieces of full length stock compared to buying singles where you have to buy a minimum. They also may have sizes that ordinary places consider odd. I was looking for 5/8 square 16 gauge and was told it would have to be shipped in from Houston (to Dallas) by my nearest supplier and found it in stock at MetalSM. But check if you get something odd - the 5/8 cost more than 3/4 at both places and MetalSM actually gave me 3/4 but took it back even though I had cut it. Also check the regular steel suppliers in your area as well as retail welders metal supply places.

- Q: How does coil slitting work?

- Coil slitting is a process used in manufacturing industries to cut large coils of material, such as metal, into narrower strips of desired widths. The coil is unwound and passed through a set of circular blades that make precise cuts along the length of the coil. The blades can be adjusted to the desired width, and the process continues until the entire coil is slit into multiple smaller coils or strips.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. However, it is typically measured in millimeters or inches, ranging from a few tenths of a millimeter to several millimeters.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- Steel is usually stable in performance. One thing is that the environment should be dry, not rain, because the damp environment is easy to rust. As long as it's in a dry room, it's basically no problem.

- Q: What are the uses of galvanized steel coils?

- Galvanized steel coils have a wide range of uses in various industries due to their unique properties. Here are some common uses of galvanized steel coils: 1. Construction: Galvanized steel coils are widely used in the construction industry for various applications. They are used to manufacture roofing sheets, wall panels, and structural components. The galvanized coating helps to protect the steel from corrosion, extending its lifespan and ensuring durability in harsh weather conditions. 2. Automotive industry: Galvanized steel coils are used in the automotive industry for manufacturing different parts and components. These coils are used to manufacture body panels, chassis, and other structural parts of vehicles. The galvanized coating provides excellent corrosion resistance, which is crucial for the longevity of automobiles. 3. Appliances: Galvanized steel coils are used in the production of various household appliances, such as refrigerators, washing machines, and air conditioners. The coils are used to manufacture the outer panels and cabinets of these appliances, providing them with a strong and durable structure. 4. Agriculture: Galvanized steel coils find applications in the agriculture sector as well. They are used to manufacture agricultural equipment, such as grain storage silos, irrigation systems, and livestock enclosures. The galvanized coating protects the steel from rust and corrosion, ensuring the safety and longevity of these agricultural structures. 5. Industrial applications: Galvanized steel coils are widely used in various industrial applications. They are used for manufacturing ductwork, ventilation systems, and industrial piping. The galvanized coating helps to resist chemicals, moisture, and other environmental factors, making it an ideal choice for industrial environments. 6. Electrical industry: Galvanized steel coils are used in the electrical industry for manufacturing electrical enclosures, conduit pipes, and cable trays. The galvanized coating provides excellent protection against corrosion and ensures the safety and durability of electrical installations. 7. Furniture manufacturing: Galvanized steel coils are used in the furniture manufacturing industry for producing furniture frames, shelves, and cabinets. The galvanized coating adds strength and durability to these furniture pieces, making them long-lasting and resistant to corrosion. Overall, galvanized steel coils have a wide range of uses in various industries due to their excellent corrosion resistance, durability, and strength. They are a cost-effective and reliable choice for applications that require protection against rust and environmental factors.

- Q: What are the common methods of inspecting steel coils for quality control?

- The common methods of inspecting steel coils for quality control include visual inspection, dimensional measurement, surface inspection, and mechanical testing. Visual inspection involves checking for any visible defects or abnormalities such as cracks, dents, or scratches. Dimensional measurement ensures that the coils meet the specified size and thickness requirements. Surface inspection involves examining the surface finish, cleanliness, and coating integrity. Mechanical testing involves conducting various tests to assess the strength, hardness, and other mechanical properties of the steel coils. These methods collectively ensure that the steel coils meet the required quality standards.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- we may use the formula ΔL=α(Lo)(Tf-To) where Lf is the length of steel at temp. Tf Lo is length at To α is the coefficient of linear expansion of steel which is 11x10^-6/°C ΔL=0.78mm (the change in length) Lo=? ΔL=α(Lo)(Tf-To) Lo=ΔL/[α(Tf-To)] Lo=(0.78x10^-3m)/[(11x10^-6/°C)(35°C-2...? Lo=5.455m answer

- Q: Can steel coils be customized according to specific requirements?

- Yes, steel coils can be customized according to specific requirements. Manufacturers can alter the dimensions, thickness, width, and other specifications of steel coils to meet the specific needs of customers.

- Q: What are the major challenges faced by steel coil manufacturers?

- Some major challenges faced by steel coil manufacturers include fluctuations in raw material prices, increasing competition from international markets, the need to meet strict quality and safety standards, and the impact of global economic conditions on demand for steel products. Additionally, environmental regulations and sustainability concerns have also become important challenges for steel coil manufacturers.

Send your message to us

PREPAINTED STEEL COIL STANDARD JIS G 3312 CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords