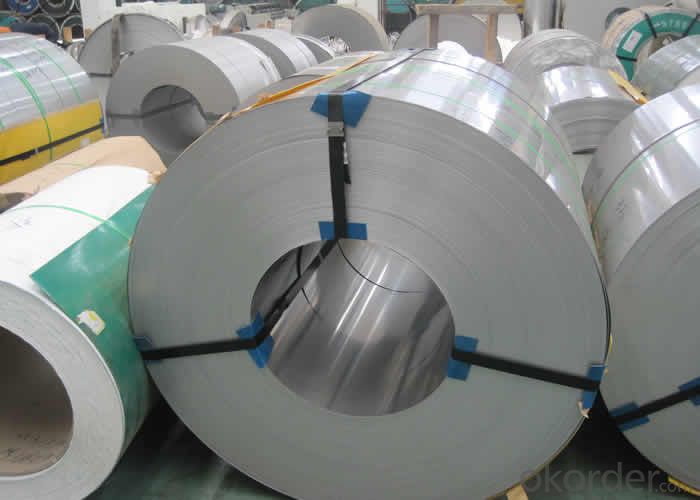

Prime Quality stainless steel coil with good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coils and Sheets

Features of Stainless Steel Coils and Sheets:

· Accurate dimension

· Suitable for heavy duty operation

· Minimum maintenance

Specifications of Stainless Steel Coils:

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.4mm-50mm

4. Width: 1000/1219/1500/1800mm

5. Length: min 1m

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Packing Information of Stainless Steel Coils and Sheets:

Please don’t worry that our products are packed, stored, transported according to the international regulation. We do care about the quality of our products; even some little details are paid attention to.

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

Plus, our storage racks are made of wood. Other kinds of metals are settled in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented.

Applications of Stainless Steel Coils and Sheets:

1.Automotive:Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers

4. Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

Technical notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: Can stainless steel sheets be cold rolled?

- Indeed, it is possible to cold roll stainless steel sheets. The cold rolling process involves passing a stainless steel sheet through a sequence of rollers at ambient temperature, leading to a decrease in thickness and an augmentation in both hardness and strength. By employing this technique, one can create stainless steel sheets with accurate measurements and impeccable surface textures. Cold rolling is widely utilized in the production of stainless steel sheets, catering to diverse sectors including automotive parts, kitchen devices, and architectural constructions.

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are highly suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, durability, and ability to withstand harsh and corrosive environments, making it an ideal material for such applications. It can effectively handle the challenges posed by wastewater treatment plants, including exposure to chemicals, moisture, and high temperatures, while maintaining its structural integrity and preventing contamination.

- Q: Welding defects analysis of 1.5mm stainless steel plate

- BurnthroughReasons: 1. The welding current is too large;The welding parts overheated;3 butt gap is too large;The welding arc is slow, long residence time.Hazard: 1. Poor surface qualityThe burn below often have pores slag pits.

- Q: Can stainless steel sheets be used in construction projects?

- Yes, stainless steel sheets can be used in construction projects. Stainless steel is a versatile and durable material that is commonly used in various construction applications. It is known for its corrosion resistance, which makes it suitable for outdoor and high-moisture environments. Stainless steel sheets are often used for roofing, wall cladding, structural components, and decorative features in buildings. They can also be used for interior applications such as countertops, backsplashes, and elevator panels. Additionally, stainless steel sheets are available in various finishes and textures, allowing for customization and aesthetic appeal in construction projects.

- Q: What are the different types of stainless steel sheet patterns available?

- There exists a variety of stainless steel sheet patterns, each possessing its own distinct design and characteristics. Some commonly encountered patterns include: 1. Smooth or plain: This pattern serves as the most elementary and widespread option, showcasing a sleek and uncomplicated surface without any discernible texture or design. 2. Satin or brushed: By subjecting the stainless steel sheet to the gentle abrasion of a fine grit abrasive, this pattern is achieved, resulting in a uniform and directional grain. It imparts a subtle and sophisticated appearance. 3. Quilted or diamond: With a raised diamond-shaped design on its surface, this pattern enhances traction and slip resistance. It finds frequent application in flooring, stairs, and industrial settings. 4. Linen: Resembling the texture of linen fabric, this pattern is achieved by etching a series of parallel lines onto the stainless steel sheet. It adds a distinctive visual appeal and is suitable for various uses, including interior design and architectural projects. 5. Perforated: Comprising a series of small holes or perforations punched into the stainless steel sheet, this pattern creates a visually captivating and functional design. It is commonly employed in situations requiring ventilation or filtration. 6. Tread or checker: Displaying a raised checkerboard design on the surface of the stainless steel sheet, this pattern offers a non-slip surface. It is often utilized in flooring, stairs, and transportation equipment. These examples merely scratch the surface of the diverse array of stainless steel sheet patterns available. Each pattern offers a unique combination of aesthetics and functionality, enabling versatile use across a wide range of applications.

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are generally resistant to pitting and crevice corrosion. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a passive oxide layer on the surface of the material, protecting it from corrosion. This oxide layer acts as a barrier, preventing the penetration of corrosive substances that could cause pitting and crevice corrosion. However, it is important to note that the resistance to pitting and crevice corrosion can vary depending on the specific grade of stainless steel and the environmental conditions in which it is exposed. Some grades of stainless steel, such as 316 or 317, have enhanced resistance to these types of corrosion. In addition, certain aggressive environments, such as those with high chloride concentrations or acidic conditions, can still pose a risk to stainless steel and may require the use of more corrosion-resistant grades or additional protective measures. Overall, stainless steel sheets are highly resistant to pitting and crevice corrosion, but the specific grade and environmental factors should be considered for optimal performance.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- Roll thickness 1 mm, width 1219 mm, length is unlimited (depending on volume weight). 304 stainless steel is a kind of the most commonly used, law-abiding.

- Q: Can stainless steel sheets be used for elevator doors?

- Elevator doors can indeed utilize stainless steel sheets. The use of stainless steel for elevator doors is quite prevalent due to its impressive attributes: its robustness, resistance to corrosion, and visually appealing nature. Stainless steel is able to withstand the daily wear and tear associated with elevator usage, remaining unscathed by scratches, dents, and stains. Moreover, stainless steel grants a sleek and contemporary appearance, rendering it a suitable material for elevator doors in various settings like commercial edifices, residential complexes, and hotels. Furthermore, stainless steel sheets can be tailored to fulfill specific design requisites, enabling a wide array of finishes, textures, and patterns to be employed, elevating the overall aesthetic of the elevator doors.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Elevator wall panels can indeed be constructed using stainless steel sheets. The utilization of stainless steel as a material for elevator interiors is highly favored due to its robustness, cleanliness, and aesthetic attractiveness. It imparts a sleek and contemporary appearance that enhances the overall look of the elevator. Furthermore, stainless steel is resistant to corrosion, staining, and scratching, rendering it suitable for high-traffic areas such as elevators. Moreover, it is effortless to clean and maintain, guaranteeing that the elevator walls remain in optimal condition for an extended period. What's more, stainless steel sheets can be tailored to meet specific design requirements and preferences, offering a plethora of finishes, patterns, and colors that can harmonize with the building or elevator's design. Ultimately, stainless steel sheets prove to be a superb option for elevator wall panels.

- Q: What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can differ depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability in comparison to carbon steel or aluminum. This is primarily because of its higher strength, hardness, and work-hardening characteristics. During machining, stainless steel tends to work-harden, resulting in increased cutting forces and tool wear. It also has lower thermal conductivity, which can lead to higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and hard-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to enhance the machinability of stainless steel. For example, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can display varying levels of machinability. Austenitic stainless steels, such as 304 and 316, are generally more challenging to machine compared to ferritic or martensitic stainless steels. This is because of their higher nickel and chromium content, which contribute to their excellent corrosion resistance but also make them harder to machine. Overall, although machining stainless steel sheets may present some difficulties, with the right tools, techniques, and expertise, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

Send your message to us

Prime Quality stainless steel coil with good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords