Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Coil Description

after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Good formability

• Good visual effect

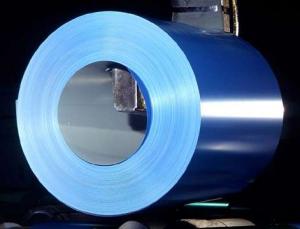

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. How long can we receive the product after purchase?

The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do steel coils contribute to sustainable construction?

- Steel coils contribute to sustainable construction in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions and resist corrosion, leading to longer-lasting structures. This durability reduces the need for frequent repairs and replacements, thereby reducing waste and conserving resources. Secondly, steel is a recyclable material, meaning that at the end of a building's life cycle, the steel used in its construction can be easily and efficiently recycled. This reduces the demand for new steel production, which is energy-intensive and releases greenhouse gases. By using steel coils made from recycled steel, the construction industry can significantly reduce its environmental impact. Additionally, steel coils are versatile and can be shaped and formed into various structural components, allowing for efficient use of materials and minimizing waste. The lightweight nature of steel coils also makes transportation and handling more cost-effective and environmentally friendly. Furthermore, using steel coils in construction can contribute to energy efficiency. Steel has excellent thermal conductivity, which means it can effectively transfer and distribute heat, enabling better insulation and reducing energy consumption for heating and cooling. Overall, steel coils play a vital role in sustainable construction by promoting durability, recyclability, efficient material usage, and energy efficiency.

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are commonly used in the oil and gas industry for various purposes such as manufacturing pipelines, storage tanks, and offshore platforms. These coils are formed into cylindrical shapes and serve as the main structural component for these applications, providing strength, durability, and resistance to extreme conditions. Additionally, steel coils are used in the production of equipment like heat exchangers, compressors, and drilling machinery, which are essential for the extraction, processing, and transportation of oil and gas.

- Q: I would like to know if steel is basically a very dense crystal, or if it is a different atomic structure

- Steel is made of billions, trillions of very small crystals. This is true of most metals. In order to see the crystal structure of steel, you usually need to cut a sample of it, grind and polish the cut face smooth, then etch the steel with a mixture of nitric acid and alcohol. Without polishing and etching the crystals aren't visible- it just looks like smooth solid metal. Also, in most cases the crystals are small enough that you need a microscope to see them clearly after etching.

- Q: How are steel coils processed for heat treatment?

- Steel coils are typically processed for heat treatment by first being uncoiled and then cleaned to remove any dirt or scale. The coils are then heated to a specific temperature, which is determined based on the desired properties of the steel. This temperature is maintained for a specific period of time to allow for the desired transformation of the steel's microstructure. After the heat treatment process is complete, the coils are cooled either slowly or rapidly, depending on the desired properties. This allows the steel to be hardened or softened as required. Finally, the coils are recoiled and prepared for further processing or shipment.

- Q: How are steel coils used in the production of railway tracks?

- Railway tracks rely heavily on steel coils, which are indispensable in their production. These coils, typically made from top-notch steel, are utilized to create the rails that constitute the bedrock of the tracks. The process commences with the unwinding of the steel coils, which are then fed into a sequence of machines that mold and fashion them into the desired rail profile. Initially, the steel coils are passed through a rolling mill, where they undergo gradual flattening and shaping, thereby transforming into elongated steel strips. This technique, known as hot rolling, involves heating the steel to high temperatures to enhance its pliability. The rolling mill exerts substantial pressure on the steel, progressively molding it into the desired rail shape. Once the steel coils have been rolled into the requisite form, they are subsequently severed into individual rail lengths. The length of these rails may vary depending on the specifications of the railway track being produced. The rail lengths then undergo further processing to eliminate any flaws and straighten them out. Following this initial shaping and processing, the rails undergo a series of supplementary treatments. These treatments may entail heat treatment to bolster their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready for installation on the railway track. They are laid out meticulously in a predetermined pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, enabling trains to travel smoothly and safely. In conclusion, steel coils are crucial components in the production of railway tracks. They are utilized to manufacture the rails that serve as the foundation of the tracks, guaranteeing durability, strength, and a smooth surface for trains to traverse. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide the raw material for producing various parts such as brackets, frames, and structural supports. These coils are processed through cutting, bending, and shaping techniques to create the necessary components that ensure the safe and efficient operation of elevators.

- Q: Already on my team is Empoleon lvl 82Heatran lvl 74Scizor lvl 34Magnezone lvl 38What other steel types should I choose?

- skarmory ferathorn lucario dialga metagross

- Q: What are the various surface finishes available for steel coils?

- Steel coils offer a range of surface finishes, each with its own properties and uses. Some commonly used finishes include: 1. Hot rolled: Steel is rolled at high temperatures, resulting in a rough surface. This finish is great for structural applications like construction materials and industrial machinery. 2. Cold rolled: Steel is rolled at room temperature, creating a smoother surface. It is commonly used in automotive and appliance manufacturing due to its superior finish and accuracy. 3. Galvanized: Steel is coated with zinc to protect against corrosion. Galvanized coils have a shiny appearance and are suitable for outdoor applications such as roofing and fences. 4. Electro-galvanized: Coated with a thinner layer of zinc through an electroplating process, these coils offer good corrosion resistance. They are commonly used in electrical appliances, automotive parts, and construction. 5. Pre-painted: Coated with paint or polymer film, pre-painted coils provide both corrosion protection and aesthetic appeal. They are extensively used in construction for roofing, cladding, and wall panels. 6. Stainless steel: Stainless steel coils have unique properties, including corrosion resistance, heat resistance, and chemical damage resistance. They are ideal for industries like food processing, medical equipment, and marine applications. These examples showcase the variety of surface finishes available for steel coils. The choice of finish depends on factors such as the intended use, desired appearance, and level of corrosion resistance required.

- Q: How are steel coils weighed?

- Steel coils are typically weighed using industrial weighing scales or load cells. These devices are capable of accurately measuring the weight of the coils, whether they are small or large in size. The coils are placed on the scale or load cells, and the weight is digitally displayed or recorded for further analysis or documentation.

- Q: Can steel coils be coated with barcodes?

- Yes, steel coils can be coated with barcodes. The barcode can be applied to the surface of the steel coil using various methods such as printing, engraving, or even attaching a barcode label. This allows for easy identification and tracking of the steel coils throughout the supply chain.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords