Pre-Painted Color Coated Steel Sheet Blue Color in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-Painted Galvanized/Aluzinc Steel Coil

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

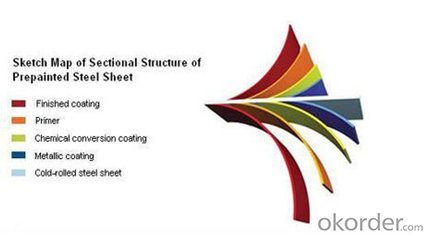

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,degrease , chemical treatment and

liquid dope with several layers of color ,then after fring and cooling ,finally become pre-painted galvanized/aluzinc steel

with good capable of decoration,molding,corrosion resistance,superior workability,

durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• Superior durability

• High manufacturing accuracy

• High strength

• Good capable of decoration

• Superior workability

• Good visual effect

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

Paint | Standard PE,PVDF,PU | Color | RAL Scale | Coil Weight | 3mt-7mt |

Packaging & Delivery

Packing: Export Standard Packing (full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips)

Delivery:30-45 Days

Size can be customized

Financial support with max 180 days unsance L/C

Prime quanlity, competitice price

Fast delivery time.

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

2) OUR SPECIFICATION OFPPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Thickness | Width | Length of plate | Inner diameter of coil | |

0.16-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Base plate | Available Coated Mass(g/m^2) |

Galvanized Steel | 30,80, 100, 120, 160, 180, 200, 275 |

Galvalume Steel | 30,50, 70, 150 ect. |

Available Painting OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 5+20microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

5.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of household goods?

- Household goods rely on steel coils for their manufacturing, utilizing them in various ways. One notable application is in the creation of appliances like refrigerators, washing machines, and ovens. These coils are skillfully molded and formed into different parts and components, fortifying the final product with durability and robustness. Moreover, furniture manufacturing frequently incorporates steel coils, specifically in constructing metal frames for chairs, tables, and bed frames. The coils can be bent, welded, or molded to desired specifications, providing a solid and dependable foundation for these essential household items. Additionally, steel coils find utility in the production of kitchen utensils and cookware. These coils can be expertly stamped or pressed into diverse shapes, including pots, pans, and cutlery. Consequently, this process generates long-lasting and heat-resistant products that are indispensable for everyday cooking and food preparation. In essence, steel coils assume a critical role in the manufacturing of household goods, imparting strength, durability, and adaptability to a wide array of products.

- Q: How do steel coils contribute to the HVACR equipment industry?

- Efficient heat transfer and effective functioning of HVACR systems are crucial roles played by steel coils in the HVACR equipment industry. These coils, made of high-quality steel, are integral components of air conditioners, heat pumps, refrigerators, and boilers. Facilitating heat transfer is one of the primary functions of steel coils in HVACR equipment. Designed to efficiently transfer heat between the refrigerant and the surrounding air or water, these coils utilize a large surface area and good thermal conductivity. As a result, HVACR equipment can effectively cool or heat a given space, ensuring optimal energy efficiency and reducing operating costs in residential and commercial applications. In addition to heat transfer, steel coils contribute to the overall durability and longevity of HVACR equipment. The use of corrosion-resistant steel in these coils helps prevent damage from moisture and other environmental factors. This reliability is particularly important as HVACR systems often face harsh conditions and must operate continuously to maintain comfortable indoor environments. Furthermore, steel coils offer versatility and customization options to meet specific HVACR requirements. Manufacturers can vary the size, shape, and configuration of the coils to fit available space and optimize performance. This flexibility enables efficient integration of steel coils into different HVACR equipment, ensuring they meet the specific heating and cooling needs of diverse environments. In conclusion, steel coils are indispensable in the HVACR equipment industry. They enable efficient heat transfer, enhance durability, and offer customization options, ensuring effective functioning and energy efficiency of HVACR systems. Manufacturers can provide reliable and long-lasting solutions for heating, ventilation, air conditioning, and refrigeration needs in residential and commercial settings by incorporating high-quality steel coils into their products.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of steps. First, the coils are unwound and fed into a machine that trims the edges to remove any irregularities or imperfections. This process ensures that the edges are smooth and straight. After trimming, the coils may undergo further conditioning, which involves heat treatment or surface coating to enhance their properties and durability. Overall, these processes are essential for producing high-quality steel coils that meet the desired specifications and standards.

- Q: and is that different from the components of steel

- Making steel is very energy intensive. Mining the raw ore requires a lot of machinery that uses fuel or electricity . Transporting the ore requires a lot of fuel. Refining not only uses a lot of electricity but coal is added to change the iron ore into steel.

- Q: Does a magnet stick to galvinied steel?

- It may have been galvanized steel but if it is now rusted, the galvanizing material has been consumed. galvanizing is a zinc layer that can be hazardous if welded. Rust is an electrochemical reaction and the zinc coating will rust away prior to the steel. if the steel is now rusting, the zinc is gone and should no longer be any more hazardous than any other welding job.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they provide structural support and help in the efficient transfer of electrical energy. They are commonly used in transformers, motors, and generators to create magnetic fields that enable the conversion and transmission of electrical power.

- Q: How do steel coils contribute to the manufacturing of electrical equipment?

- Due to their unique properties and versatility, steel coils play a crucial role in the manufacturing of electrical equipment. Transformer cores, essential components in electrical equipment, rely on steel coils for efficient energy transfer and reduced energy losses. The magnetic properties of steel make it an ideal material for transformer cores, allowing for the transformation of voltage levels and ensuring proper equipment functioning. In addition, steel coils are widely used in the production of motors and generators, which convert electrical energy into mechanical energy and vice versa. The coil shape of steel enables the creation of electromagnetic fields, necessary for the operation of motors and generators. Moreover, the strength and durability of steel coils enable them to withstand high temperatures and mechanical stresses commonly encountered in electrical equipment. Furthermore, steel coils are utilized in the construction of electrical conductors, including wires and cables, enabling the transmission of electricity from power sources to various electrical devices. Steel's high electrical conductivity ensures efficient power transmission, while also providing mechanical strength and protection against corrosion and wear. The coil shape of steel wires enhances their flexibility, making them suitable for various applications in electrical equipment manufacturing. Overall, steel coils make a significant contribution to the manufacturing of electrical equipment by providing the necessary magnetic properties for transformer cores, enabling the generation of electromagnetic fields in motors and generators, and facilitating efficient power transmission in electrical conductors. Their versatility, strength, and durability make them an indispensable component in the production of reliable and high-performance electrical equipment.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they provide the raw material for forming the enclosures' outer shells and structural components. The steel coils are processed and shaped through various techniques such as cutting, bending, and welding, to create the desired size and shape of the enclosure. The steel's strength and durability make it an ideal material choice for ensuring the enclosures can protect electrical equipment from environmental factors and provide safety for users.

- Q: I would like to build steel galvanization plant.

- How big of a kettle do you want to go with? A small 6-10 foot kettle would work fine for spinner work (small parts ran in baskets) but if you want to handle large beams and so forth you will need to have at least a 25 foot or longer kettle. You will need tanks for caustic,acid,rinsing,and preflux solutions. If you go with sulfuric acid it will have to be heated. The caustic and flux tanks need to be heated in any case.You will also need a bag house to control smoke coming off the kettle. First you should look into permits such to see if you can actually build this plant. Galvanizing is nasty work and the laws and regs are strict. Former Kettleman

- Q: What is the process of recoiling steel coils?

- The process of recoiling steel coils involves rewinding or unrolling large steel coils to create smaller, more manageable coils. This process is typically carried out in steel processing plants or coil service centers. The first step in the recoiling process is to identify the appropriate coil to be recoiled. This selection is based on factors such as coil size, weight, and quality. Once the coil is chosen, it is placed onto a recoiling machine, which is equipped with various mechanisms to facilitate the recoiling process. The recoiling machine consists of a mandrel or drum, around which the coil is wound or unwound. The coil is secured onto the mandrel, either by mechanical clamps or hydraulic pressure, to ensure it remains stable during the recoiling process. In the case of rewinding or recoiling a large coil into smaller coils, the machine starts by unwinding the original coil. This is done by rotating the mandrel in the opposite direction, causing the coil to gradually unroll. As the coil unwinds, it passes through various straightening and flattening mechanisms, which help to ensure the coils are produced with consistent dimensions and quality. Once the original coil is completely unwound, the machine starts the rewinding process. The smaller coils are created by winding the steel strip onto the mandrel in a controlled manner. The speed and tension of the rewinding process are carefully regulated to prevent any damage to the steel strip. During the recoiling process, various quality control measures are implemented to ensure the produced coils meet the desired specifications. These may include monitoring the thickness, width, and surface quality of the steel strip, as well as conducting periodic inspections to detect any defects or irregularities. Once the rewinding process is completed, the smaller coils are typically removed from the mandrel and prepared for further processing or shipment. This may involve applying protective coatings, labeling, or packaging the coils, depending on their intended use. In summary, the process of recoiling steel coils involves unwinding large coils, straightening and flattening the steel strip, and rewinding it onto a mandrel to create smaller, more manageable coils. This process requires specialized machinery and careful control to ensure the quality and consistency of the recoiled coils.

Send your message to us

Pre-Painted Color Coated Steel Sheet Blue Color in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords