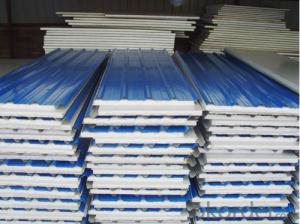

Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet For Different Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted steel coil

Specifications

1.Standard: ASTM,GB,JIS

2.Grade : DX51D+Z

3.Thickness: 0.18-1.5mm

4.Width:914-1250mm

5.Top paint:20mil,Black paint:7mil

6. Technical/Surface treatment: color coated/galvanized/galvalume

7..Useage: widely used in construction,home,appliance,decoration,wear resistant steel,etc.

Advantages:

1. more than 10 years experiences in steel b2usiness

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

Company :

CNBM is the specialized manufacturer of the prepainted steel coil ,

including the PPGI and PPGL . And our products have exported to Korea , Southeast Asia ,

Russia , Middle East ,South America ,South Africa ,Northern Europe and do on .

Product :

Commodity : | Prepainted steel coil /PPGI /PPGL |

Materials Grade: | SGCC ,CGCC ,DX51D+Z ,SGLCC |

Thickness : | 0.17-1.2mm |

Width : | 914mm,1219mm,1000mm,1220mm,1250mm ( can cut to strip above 30mm width ) |

Zinc coating : | 60-275g/sqm |

Surface Structure: | Galvanized Or Aluzinc |

Color : | RAL No. or Sample color |

Painting : | Top : 5micron primer +15-20microns polyester |

Coil Weight : | 2-6mts |

Payment term : | TT ,L/C AT SIGHT , USANCE L/C ,D/P |

Shipment : | 20 feet container or bulk ship |

Remark : | We accept the third-party inspection ,such as SGS , |

FAQ

1. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your MOQ?

25MT, it is for one container.

4.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: I work in a steel foundry 10-12 hours a day where we melt and pour stainless steel tubes. The pour temperature for some of them is very close to the boiling point of stainless steel (about 3800 degrees) because it has to be VERY liquid for the application we use it. Anyway, it does boil a little and we breath in the vapours which I can assure you ARE indeed vapourized stainless steel (it collects and cools on everything and makes a nice shiny coating). Ok, so to the question, does breathing vapourized stainless steel all day pose a health risk such as cancer? Anyone know? I'm just curious.

- I would imagine it's not good. I doubt cancer but I suppose it may be possible. Shouldn't you guys have respirator gear on? Where's OSHA when you need'em? ;)

- Q: Can steel coils be painted?

- Yes, steel coils can be painted. Painting steel coils helps to protect them from corrosion and enhance their appearance. The coils are typically cleaned, primed, and then painted using specialized coatings to ensure proper adhesion and durability.

- Q: What are the challenges faced in the recycling of steel coils?

- One of the main challenges in recycling steel coils is the process of separating the different materials that may be attached to the coils, such as plastic or paper. These contaminants need to be removed before the steel can be recycled efficiently. Additionally, the size and weight of steel coils can pose logistical challenges in terms of transportation and storage. Lastly, ensuring that the recycled steel meets the required quality standards and specifications is another challenge faced in the recycling process.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- Personally, okorder They are spot on for sizing, they do customs, and amazing quality like i have never seen before and I have been through a lot of plugs. Hope this helps :)

- Q: What are the common standards and specifications for steel coils?

- The common standards and specifications for steel coils include ASTM A36/A36M, ASTM A572/A572M, ASTM A1011/A1011M, and ASTM A653/A653M. These standards outline the requirements for the chemical composition, mechanical properties, dimensions, and other characteristics of steel coils used in various industries, such as construction, automotive, and manufacturing. Additionally, international standards like EN 10025 and JIS G3101 are also commonly followed in different regions.

- Q: How are steel coils used in the automotive industry?

- Steel coils are widely used in the automotive industry for various applications such as body panels, structural components, and engine parts. They are typically formed and shaped into desired forms through processes like stamping, bending, and welding. Steel coils provide strength, durability, and corrosion resistance to the vehicles, ensuring their safety and longevity.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- There are several different methods of cut-to-length shearing for steel coils, including rotary shearing, flying shear, stationary shear, and programmable logic controller (PLC) controlled shear. Each method has its own advantages and is used based on factors such as coil thickness, desired precision, and production speed requirements.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Manufacturers can produce steel coils in various dimensions and thicknesses to meet specific requirements and applications.

- Q: is it much difference between 1095 and 1080,,,1065,,,1060 or even 1045 steel?please help and thanks!

- In okorder /

- Q: How are steel coils used in the production of structural components?

- Steel coils are used in the production of structural components as they serve as the primary raw material for various manufacturing processes. These coils are typically processed through rolling mills, where they are heated, shaped, and transformed into different structural shapes, such as beams, columns, and plates. The high strength and durability of steel make it an ideal choice for constructing buildings, bridges, and other infrastructure, ensuring the structural integrity and longevity of these components.

Send your message to us

Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet For Different Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords