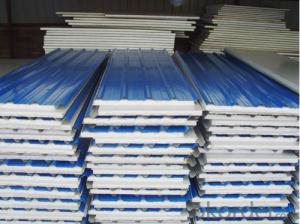

Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted steel coil

Specifications

1.Standard: ASTM,GB,JIS

2.Grade : DX51D+Z

3.Thickness: 0.18-1.5mm

4.Width:914-1250mm

5.Top paint:20mil,Black paint:7mil

6. Technical/Surface treatment: color coated/galvanized/galvalume

7..Useage: widely used in construction,home,appliance,decoration,wear resistant steel,etc.

Advantages:

1. more than 10 years experiences in steel b2usiness

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

Company :

Tianjin Liwei Iron&Steel Co.,Ltd is the specialized manufacturer of the prepainted steel coil ,

including the PPGI and PPGL . And our products have exported to Korea , Southeast Asia ,

Russia , Middle East ,South America ,South Africa ,Northern Europe and do on .

Product :

| Commodity : | Prepainted steel coil /PPGI /PPGL |

| Materials Grade: | SGCC ,CGCC ,DX51D+Z ,SGLCC |

| Thickness : | 0.17-1.2mm |

| Width : | 914mm,1219mm,1000mm,1220mm,1250mm ( can cut to strip above 30mm width ) |

| Zinc coating : | 60-275g/sqm |

| Surface Structure: | Galvanized Or Aluzinc |

| Color : | RAL No. or Sample color |

| Painting : | Top : 5micron primer +15-20microns polyester Back : 5-8microns primer epoxy |

| Coil Weight : | 2-6mts |

| Payment term : | TT ,L/C AT SIGHT , USANCE L/C ,D/P |

| Shipment : | 20 feet container or bulk ship |

| Remark : | We accept the third-party inspection ,such as SGS , INSPECTORATE ,CIQ |

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- Stick Welding Stainless Steel

- Q: What are the different methods of tempering steel coils?

- There are several different methods of tempering steel coils, each with its own advantages and disadvantages. Some of the most common methods include: 1. Air cooling: This is the simplest and most common method of tempering steel coils. The coils are heated to a specific temperature and then allowed to cool naturally in ambient air. This method is relatively quick and cost-effective, but it can result in uneven cooling and may not provide as precise control over the final properties of the steel. 2. Water quenching: In this method, the steel coils are heated and then rapidly cooled by immersing them in a bath of water. Water quenching provides a more rapid and controlled cooling rate than air cooling, resulting in greater hardness and strength. However, it can also lead to increased distortion and the formation of internal stresses in the steel. 3. Oil quenching: Similar to water quenching, oil quenching involves immersing the steel coils in a bath of oil to rapidly cool them. Oil quenching provides a slower and more uniform cooling rate compared to water quenching, resulting in reduced distortion and internal stresses. However, it also produces slightly lower hardness and strength compared to water quenching. 4. Salt bath quenching: This method involves immersing the steel coils in a heated bath of molten salt to rapidly cool them. Salt bath quenching provides an even and controlled cooling rate, resulting in improved hardness and strength compared to air or water quenching. However, it requires specialized equipment and may not be suitable for all types of steel. 5. Induction hardening: In this method, the steel coils are heated using an induction heating process and then rapidly cooled using either air, water, or oil quenching. Induction hardening allows for precise control over the heating and cooling process, resulting in specific hardness and strength properties in desired areas of the steel. However, it requires specialized equipment and is typically used for specific applications or parts of the steel coils. Overall, the choice of tempering method depends on various factors such as the desired properties of the steel coils, the type of steel being used, and the specific requirements of the end application.

- Q: How are steel coils protected from chemical damage?

- Steel coils are typically protected from chemical damage through various methods such as applying protective coatings or using barrier films. These protective measures act as a barrier between the steel surface and any potentially corrosive chemicals, preventing direct contact and minimizing the risk of chemical damage.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: it seems like the hardness of Stainless steel, i saw 410c stainless stell, i saw 440c stainless steel, what does it means anyway?

- It is the alloy number given by the American Iron and Steel Institute, or AISI. This is the trade organization of the U.S. steel industry, one of the oldest such organizations. 440C is also known under the UNS system as S44004 440C is a high carbon, plain chromium stainless steel. Or more specifically: 18% Cr, ~1.1% C, ~1.0% Mo, Si, and Mn 440c is mostly used in cutlery, bearings, and valve parts; because it has the best strength and hardness after basic heat treatment of any stainless steel. Relatively poor properties in other areas make it less suitable for other types of items. for example 440c becomes very brittle in sub zero temperatures. 410 is similar to 440, but it is a cheaper milder steel with less chromium and carbon, so it is less brittle, more easily worked and machined, but lacks final strength and hardness. it is often used in cheap stainless fasteners and bushings.

- Q: What are the advantages of using steel coils in the manufacturing industry?

- There are several advantages of using steel coils in the manufacturing industry. Firstly, steel coils provide excellent strength and durability, making them ideal for applications that require high load-bearing capacity. Secondly, steel coils are highly resistant to corrosion, making them suitable for outdoor or harsh environments. Additionally, steel coils offer consistent and uniform properties, ensuring reliable and precise manufacturing processes. Moreover, steel coils can be easily formed and shaped, allowing for versatile use in various industries. Lastly, steel coils are recyclable, making them an environmentally friendly choice.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials. Coating steel coils with heat-resistant materials provides protection against high temperatures and ensures the durability and longevity of the coils in various industrial applications.

- Q: Ok, so I'm obsessed with learning how to play the guitar (I preffer acoustic)... I'm a teenage girl that wants to play rock/pop/folk music... I want to learn first how to strum... then eventually how to pick...so what type of string is better? nylon or steel?

- Nylon Guitar Strings Vs Steel

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- I loved the new interpretation in Man of Steel Superman Returns got very poor reviews in the beginning, and as the hatred has worn off and fans have been the only ones voting, the score has moved up. As fond as I am of Christopher Reeves, his version was a touch campy. I much prefer the serious treatment.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are rolled and shaped into various structural components like beams, girders, and plates. These coils provide the necessary strength, durability, and flexibility required to support heavy loads and withstand the dynamic forces exerted on the bridge.

Send your message to us

Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords