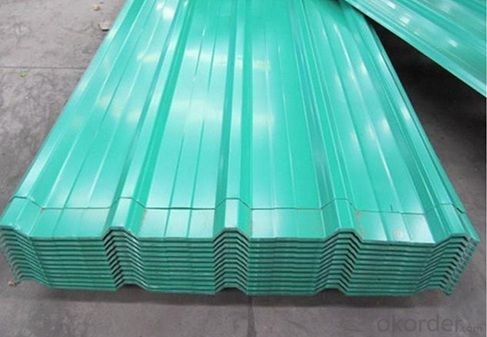

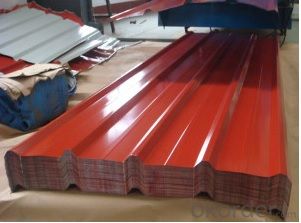

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the factors that affect the hardness of steel strips?

- The hardness of steel strips can be affected by various factors. 1. The carbon content in steel plays a significant role in determining its hardness. Higher carbon content generally results in increased hardness. 2. The hardness of steel strips can also be influenced by the presence of certain alloying elements like chromium, manganese, and molybdenum. These elements can form carbides and enhance the overall hardness of the material. 3. The hardness of steel strips is greatly influenced by the heat treatment process, which includes quenching and tempering. Quenching involves rapidly cooling the material, while tempering is a subsequent heating process that improves toughness and reduces brittleness. 4. The cooling rate during the manufacturing process can affect the hardness of steel strips. Faster cooling methods, like water quenching, can result in a harder material compared to slower cooling methods. 5. The size of the grains in the steel structure can impact its hardness. Smaller grain sizes generally lead to increased hardness due to a more uniform distribution of carbon and alloying elements. 6. Impurities like sulfur and phosphorous can have a negative impact on the hardness of steel strips. These impurities can form brittle compounds and reduce the overall hardness of the material. 7. Cold working processes such as rolling or drawing can increase the hardness of steel strips. This deformation process introduces dislocations, which in turn increase the strength and hardness. 8. The composition and microstructure of the steel, including the presence of phases like martensite, ferrite, and pearlite, can influence its hardness. These phases form during cooling and contribute to different levels of hardness. It is important to consider that the hardness of steel strips often involves a trade-off with other properties such as toughness and ductility. Therefore, finding the right balance between hardness and other desired characteristics is crucial for specific applications.

- Q: How are steel strips used in the production of power cables?

- Steel strips are used in the production of power cables to provide strength and reinforcement to the cables, ensuring their durability and ability to withstand mechanical stress during installation and operation.

- Q: How do steel strips contribute to fire resistance in various applications?

- The fire resistance of different applications is improved by the presence of steel strips, which contribute through structural integrity and fire containment. Steel possesses inherent fire resistance due to its high melting point and low thermal conductivity. When utilized as strips or reinforcements, steel has the ability to enhance the fire resistance of diverse materials and structures. Construction commonly employs steel strips in the form of fire-resistant coatings or as reinforcing elements within concrete structures. Fire-resistant coatings that contain steel strips create a barrier that shields the underlying material from heat and flames. These coatings possess the capability to delay the spread of fire, provide insulation, and prevent structural collapse. Concrete structures also benefit from the inclusion of steel strips in enhancing fire resistance. When embedded in concrete, steel reinforcement bars or strips increase the structure's strength and durability. In the event of a fire, the steel strips aid in maintaining the concrete's structural integrity, preventing it from crumbling or collapsing under high temperatures. Moreover, steel strips are frequently utilized in fire doors and fire-rated partitions. These strips offer additional strength and stability to the doors and partitions, rendering them more fire-resistant and hindering the spread of flames and smoke. Steel strips in fire doors can also function as thermal barriers, reducing heat transfer and safeguarding the surrounding areas. In industrial applications, steel strips are employed in the manufacture of fire-resistant cables. These cables are engineered to endure high temperatures and retain their functionality during fire emergencies. Steel strips within the cables provide mechanical strength and protection against heat, ensuring that critical electrical systems remain operational in environments prone to fire. In conclusion, steel strips fulfill a crucial role in enhancing fire resistance across various applications, providing structural support, containment, and insulation. Whether utilized in coatings, concrete reinforcement, fire doors, or fire-resistant cables, steel elevates the overall fire resistance of materials and structures, ultimately safeguarding lives and property in the event of a fire.

- Q: How are steel strips processed for formability?

- To enhance the formability of steel strips, various manufacturing techniques are employed. These techniques aim to improve the strips' ability to be shaped and formed into different products. The processes involved include annealing, tempering, and cold rolling. The initial step in improving the formability of steel strips is annealing. This process entails heating the strips to a specific temperature and gradually cooling them down. By doing so, internal stresses are relieved, and the steel becomes more malleable. This enables it to be bent or formed without cracking or breaking. Another crucial process that enhances formability is tempering. After annealing, the strips are reheated to a lower temperature and rapidly cooled. This further enhances the ductility and toughness of the steel, making it more resistant to cracking during forming operations. Cold rolling is the final stage in the formability processing of steel strips. This involves passing the strips through a series of rollers at room temperature, which reduces their thickness and enhances their surface finish. Cold rolling not only improves the formability of the steel but also enhances its mechanical properties, such as strength and hardness. Apart from these primary processes, secondary techniques can also be employed to further enhance formability. These may include surface treatments, such as the application of lubricants or coatings, to reduce friction and improve the material's ability to slide and deform during forming operations. In summary, the processing of steel strips for formability is a meticulously planned series of manufacturing techniques. Through annealing, tempering, cold rolling, and other secondary processes, steel strips become more malleable, ductile, and resistant to cracking. This facilitates efficient and successful forming operations.

- Q: How are steel strips coated with a protective oil film?

- Steel strips are coated with a protective oil film through a process called oiling or oil coating. This process involves the application of an oil-based substance onto the surface of the steel strips to provide a layer of protection against corrosion and other forms of damage. The oil coating can be applied using various methods, including immersion, brushing, spraying, or roll-coating. In immersion coating, the steel strips are submerged into a bath of oil, allowing the oil to penetrate the surface and form a protective film. Brushing involves manually applying the oil onto the surface using brushes or rollers, ensuring an even and consistent coating. Spraying is another method where the oil is atomized and sprayed onto the steel strips, covering the entire surface area. Roll-coating, as the name suggests, involves passing the steel strips through rollers that have been soaked in oil, effectively transferring the oil onto the surface. The type of oil used for coating can vary depending on the specific requirements and desired properties of the steel strips. Common oils used include mineral oils, synthetic oils, rust preventatives, and lubricants. These oils are chosen based on their ability to provide corrosion protection, lubrication, and other desired characteristics. Once the oil coating is applied, the steel strips may go through additional processes such as drying or curing to ensure the oil film adheres properly to the surface. This may involve passing the strips through ovens or using other methods to remove any excess oil or moisture and promote the bonding of the protective film. Overall, the process of coating steel strips with a protective oil film is crucial in enhancing their durability and preventing damage during storage, transportation, and subsequent processing. The oil film acts as a barrier against moisture, oxygen, and other elements that can lead to corrosion, rusting, or surface defects.

- Q: Are steel strips used in the production of kitchen utensils?

- Yes, steel strips are commonly used in the production of kitchen utensils due to their durability and corrosion resistance.

- Q: What is the cost of steel strips compared to other materials?

- The cost of steel strips can vary depending on factors such as the type of steel, thickness, and market conditions. However, generally speaking, steel strips tend to be more cost-effective compared to other materials commonly used in various industries.

- Q: What are the welding techniques used for steel strips?

- Some commonly used welding techniques for steel strips include butt welding, lap welding, and spot welding.

- Q: What is the price of steel strips?

- The price of steel strips can vary depending on factors such as the grade of steel, market demand, and supplier. It is best to contact specific manufacturers or suppliers to get accurate pricing information.

- Q: What are the environmental impacts of steel strip production?

- The production of steel strips has various effects on the environment. Firstly, when extracting iron ore, the main raw material for steel production, open-pit mining or underground mining are often used, causing deforestation, habitat destruction, and soil erosion. Additionally, the mining process requires large amounts of water, potentially depleting local water sources and causing water pollution due to the discharge of heavy metals and other contaminants. The next step in steel strip production involves converting iron ore into steel through a process called smelting. This process requires significant amounts of energy, usually obtained from fossil fuels, resulting in greenhouse gas emissions and contributing to climate change. The burning of fossil fuels also releases air pollutants like sulfur dioxide, nitrogen oxides, and particulate matter, which can negatively impact air quality, human health, and ecosystems. Furthermore, during the steel strip production process, various chemicals and additives are commonly used, including limestone, coke, and coal tar. If not managed properly, these substances can contaminate water and soil, posing risks to aquatic life and potentially entering the food chain. The disposal of waste generated during steel production, such as slag and scale, can also have environmental consequences. Slag, a byproduct of the smelting process, is often dumped in landfills, occupying valuable space and potentially releasing harmful substances into the surrounding soil and groundwater. Lastly, the transportation of iron ore, coal, and other materials required for steel strip production contributes to carbon emissions from the burning of fossil fuels in transportation vehicles. To address these environmental impacts, efforts are being made to enhance the efficiency of steel production processes, reduce energy consumption, and increase the use of renewable energy sources. Recycling steel is another crucial strategy to minimize the environmental footprint of steel strip production, as it reduces the need for extracting raw materials and energy-intensive smelting processes. Additionally, implementing appropriate waste management practices and treating wastewater from steel mills can help minimize pollution risks.

Send your message to us

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords