cold rolled steel coil DC03

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

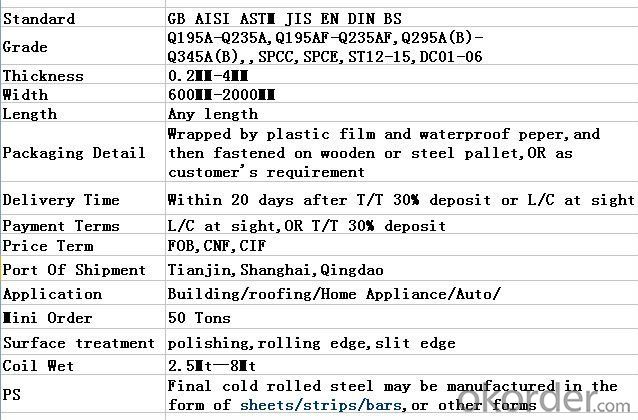

| Packaging Detail: | Wrapped by plastic film and waterproof peper,and then fastened on wooden or steel pallet,OR as customer's requirement |

| Delivery Detail: | Within 20 days after T/T 30% deposit or L/C at sight |

Specifications

Cold rolling / cold rolled sheet / cold rolled roils / cold rolled plate

Q195A-Q345A,,SPCC,SPCD,SPCE,ST12-15,DC01-06

- Q: What is the typical coefficient of thermal expansion of steel strips?

- The typical coefficient of thermal expansion of steel strips can vary depending on the specific type of steel and its composition. However, a general range for the coefficient of thermal expansion of steel is between 10 and 14 parts per million per degree Celsius (ppm/°C). This means that for every degree Celsius increase in temperature, the steel strip will expand by approximately 10-14 parts in length per million parts of its original length. It is important to note that this value can be influenced by factors such as the presence of alloying elements and the specific heat treatment applied to the steel. Therefore, it is advisable to consult the specific technical data or manufacturer's specifications to determine the precise coefficient of thermal expansion for a particular grade or alloy of steel strip.

- Q: Can steel strips be used in the manufacturing of bicycles?

- Yes, steel strips can be used in the manufacturing of bicycles. Steel is a commonly used material in bicycle frames due to its strength, durability, and affordability. Steel strips can be shaped and welded to form the frame, providing a sturdy structure for the bicycle.

- Q: What is the width tolerance of steel strips?

- The width tolerance of steel strips can vary depending on the specific requirements and specifications set by the manufacturer or customer. However, common width tolerances for steel strips typically range from +/- 0.005 to 0.020 inches.

- Q: How do steel strips handle wear and tear?

- Steel strips are highly durable and resistant to wear and tear. They can withstand heavy loads, abrasion, and impact without losing their structural integrity. Additionally, steel strips can be treated with various coatings or surface treatments to enhance their resistance to corrosion and other forms of deterioration. Overall, steel strips are known for their long lifespan and ability to handle wear and tear effectively.

- Q: Can steel strips be used in food processing or medical applications?

- Yes, steel strips can be used in food processing or medical applications. Steel strips are commonly used in the food processing industry for various purposes such as cutting, slicing, or packaging equipment. In medical applications, steel strips are used for manufacturing surgical instruments, implants, or medical devices due to their durability, corrosion resistance, and biocompatibility.

- Q: How are steel strips used in the production of metal shelving?

- Steel strips are used in the production of metal shelving to provide structural support and stability. These strips are typically shaped and formed into brackets or supports that reinforce the shelves, ensuring they can hold heavy loads without bending or collapsing. The strips may also be used to create the frame or framework of the shelving unit, providing a strong and durable structure.

- Q: How are steel strips processed for engraving?

- Steel strips are processed for engraving through a series of steps that involve preparation, engraving, and finishing. Firstly, the steel strips are cleaned and degreased to remove any dirt or oil, ensuring a smooth surface for engraving. This is typically done using solvents or chemical cleaners. Once the strips are clean, they are usually coated with a layer of photoresist material. This photoresist acts as a protective barrier against the engraving process. The steel strips are then exposed to UV light through a pattern or template, which hardens the photoresist in specific areas. Next, the strips undergo the actual engraving process. This can be done using different techniques, such as chemical etching or laser engraving. In chemical etching, the steel strips are immersed in an etching solution that selectively removes the unprotected areas of the photoresist, exposing the steel underneath. On the other hand, laser engraving uses a focused laser beam to directly remove the photoresist and etch the steel. After the engraving is complete, the remaining photoresist is typically stripped off using a chemical solution or mechanical methods. This reveals the engraved design on the steel strips. Depending on the desired finish, the strips may undergo further treatments like polishing or coating to enhance the appearance and durability of the engraving. Overall, the process of engraving steel strips involves cleaning, coating with photoresist, exposing to UV light, engraving, removing the photoresist, and applying finishing touches. This ensures precise and detailed engravings on the steel strips, making them suitable for various applications such as decorative items, industrial marking, or identification tags.

- Q: How are steel strips embossed or patterned?

- Steel strips can be embossed or patterned through a process called roll forming, where the steel strip is passed through a series of rolls containing engraved patterns or designs. The pressure exerted by the rolls on the steel strip creates the desired embossed or patterned effect.

- Q: What are the mechanical properties of steel strips?

- Steel strips are widely used in various industries due to their numerous important mechanical properties. One such property is their strength, as steel is known for its high tensile strength, enabling it to withstand heavy loads and forces without deforming or breaking. This strength is particularly crucial in applications where structural integrity is of utmost importance, such as in building construction, automotive manufacturing, and aerospace. Another significant mechanical property of steel strips is their hardness, which can be achieved through heat treatment. The level of hardness affects the steel's resistance to wear, abrasion, and indentation. Harder steel strips are often utilized in applications where durability and resistance to surface damage are critical, such as in cutting tools, metalworking machinery, and industrial equipment. Steel strips also exhibit excellent stiffness and elasticity, allowing them to maintain their shape and return to their original form even after being subjected to external forces. This property is particularly valuable in applications that require dimensional stability, such as in springs, fasteners, and precision components. Moreover, steel strips possess good ductility, meaning they can be easily shaped and formed without breaking. This characteristic allows for the creation of complex and intricate designs, making steel strips suitable for applications like sheet metal fabrication, stamping, and forming processes. Furthermore, steel strips demonstrate excellent fatigue resistance, enabling them to endure repeated loading and unloading cycles without experiencing failure. This property is crucial in applications subjected to cyclic stress, including machinery components, bridges, and structural frameworks. In addition to these properties, steel strips also possess good thermal conductivity, allowing them to efficiently transfer heat. This advantage is particularly beneficial in applications that require heat dissipation or temperature regulation, such as in heat exchangers, radiators, and electrical appliances. To conclude, the mechanical properties of steel strips, including their strength, hardness, stiffness, ductility, fatigue resistance, and thermal conductivity, make them a versatile and reliable material suitable for a wide range of applications in various industries.

- Q: How are steel strips used in the automotive supply chain?

- Steel strips are used in various ways in the automotive supply chain. They are commonly used for manufacturing components such as body panels, chassis parts, and reinforcements. These strips are often processed and shaped through techniques like stamping, bending, and welding to create specific automotive parts. Additionally, steel strips are utilized for strengthening and reinforcing structures, improving vehicle safety and durability. Overall, steel strips play a crucial role in the production and assembly of automobiles, helping to ensure their strength, stability, and performance.

Send your message to us

cold rolled steel coil DC03

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords