prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Corrugated sheet | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

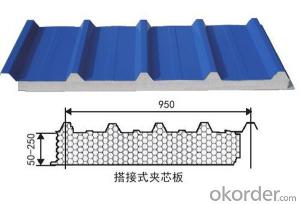

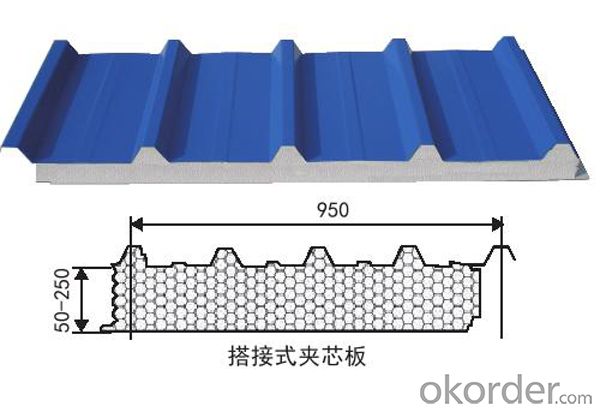

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: How do steel sheets perform in high-pressure environments?

- Steel sheets are highly resilient and perform exceptionally well in high-pressure environments. Due to their inherent strength and durability, steel sheets can withstand and effectively contain the immense pressure exerted on them. This makes them a preferred choice in applications such as pressure vessels, pipelines, and industrial machinery. The high-pressure environment puts significant stress on materials, but steel sheets have the ability to resist deformation and maintain their structural integrity under these conditions. Their exceptional tensile strength and ability to withstand compressive forces without buckling or breaking make them a reliable choice for withstanding high pressure. Furthermore, steel sheets are known for their excellent corrosion resistance. This is particularly important in high-pressure environments since it helps prevent any potential leaks or failures due to corrosion-induced weakening. Steel sheets can be further enhanced with coatings or treatments to provide additional protection against corrosion, making them even more suitable for such demanding applications. Steel sheets also offer a high degree of versatility and can be easily fabricated into various shapes and sizes to meet specific requirements. This adaptability allows for the customization of steel sheets to suit different high-pressure environments, ensuring an optimal performance in a range of industrial settings. In summary, steel sheets are highly reliable and perform exceptionally well in high-pressure environments. Their strength, durability, resistance to deformation, and corrosion resistance make them a preferred choice for applications where containment of high-pressure substances is essential.

- Q: What is the maximum temperature resistance of steel sheets?

- The maximum temperature resistance of steel sheets is dependent on the specific type of steel and its composition. Stainless steel, in general, exhibits good heat resistance and can endure temperatures up to approximately 1200 degrees Celsius (2200 degrees Fahrenheit) while maintaining its strength and structural integrity. Conversely, high carbon steels can tolerate temperatures up to around 900 degrees Celsius (1650 degrees Fahrenheit) before experiencing a decline in their mechanical properties. It should be noted that these temperature limits are approximate and subject to variation based on factors such as exposure duration, the presence of other elements or impurities in the steel, and the specific application of the steel sheets. Consequently, it is always prudent to refer to the manufacturer's specifications or conduct further research to ascertain the precise maximum temperature resistance of a specific type of steel sheet.

- Q: Are steel sheets suitable for data center infrastructure?

- Yes, steel sheets are suitable for data center infrastructure. Steel is a strong and durable material that can provide the necessary structural integrity and support for data center equipment and systems. It is commonly used for server racks, cabinets, enclosures, and other components within data centers. Steel sheets offer stability, protection, and easy customization options, making them a reliable choice for data center infrastructure.

- Q: What is the difference between a HRPO and HRSPO steel sheet?

- HRPO and HRSPO are both types of steel sheets, but they differ in their manufacturing process and resulting properties. HRPO stands for Hot Rolled Pickled and Oiled, while HRSPO stands for Hot Rolled Skin Passed and Oiled. The HRPO steel sheet is made by subjecting a hot rolled steel coil to a pickling process, which involves removing impurities and scale from the surface using an acid bath. After pickling, the steel sheet is then oiled to prevent corrosion during storage and transportation. This process results in a smooth and clean surface finish. On the other hand, the HRSPO steel sheet undergoes an additional skin pass process after pickling and oiling. During the skin pass process, the steel sheet is passed through a set of rolls to improve the surface finish and reduce its thickness. This process also imparts a certain level of cold work to the steel, enhancing its mechanical properties. In terms of properties, HRPO steel sheets exhibit good formability, weldability, and paintability due to their clean surface and lack of scale. They are commonly used in applications that require a smooth surface finish, such as appliances, automotive parts, and exposed architectural components. HRSPO steel sheets, with their improved surface finish and reduced thickness, offer even better formability and surface quality compared to HRPO sheets. They are often used in more demanding applications where precise dimensional control and surface aesthetics are crucial, such as automotive body panels, electrical enclosures, and furniture manufacturing. In summary, the main difference between HRPO and HRSPO steel sheets lies in the additional skin pass process that HRSPO undergoes, resulting in improved surface finish, reduced thickness, and enhanced mechanical properties. The choice between the two depends on the specific requirements of the application in terms of surface quality, dimensional control, and mechanical performance.

- Q: What is the maximum size available for steel sheets?

- The maximum dimensions of steel sheets can differ based on the type and grade of steel used and the manufacturing capabilities of the supplier. Generally, steel sheets can be produced in sizes ranging from small sheets measuring a few inches in width and length, to large sheets measuring several feet or even meters in width and length. The transportation and handling restrictions can also affect the maximum size of steel sheets available, as larger sheets might be harder to transport and manipulate. To determine the maximum size of steel sheets that fit your specific needs, it is advisable to consult with a steel supplier.

- Q: Can steel sheets be used in high-temperature environments?

- Yes, steel sheets can be used in high-temperature environments. Steel is known for its high strength and resistance to heat, making it a suitable material for applications that involve elevated temperatures. However, the specific type of steel and its composition should be considered to ensure it can withstand the desired temperature range without excessive deformation or deterioration.

- Q: Can the steel sheets be used for storage cabinets?

- Indeed, storage cabinets can be constructed using steel sheets. Steel, a robust and enduring material, is frequently employed in the fabrication of cabinets and alternative storage options. By manipulating steel sheets, one can effortlessly fashion them into the preferred dimensions and style for cabinets, resulting in a resilient and dependable storage solution. Furthermore, steel possesses resistance to corrosion, rendering it ideal for preserving a multitude of items and guaranteeing the cabinets' durability.

- Q: What are the common thicknesses for roofing steel sheets?

- Roofing steel sheets come in a variety of thicknesses, typically ranging from 0.4mm to 0.8mm. Nevertheless, the actual thickness required will be influenced by factors like the roofing system type, regional climate, and desired durability level. In regions prone to harsh weather, thicker steel sheets, like those around 0.8mm, are commonly employed, whereas thinner sheets may suffice for less challenging environments. Consulting with a roofing expert or manufacturer is crucial to ascertain the ideal thickness for a particular roofing undertaking.

- Q: Steel plate pile length, adjacent two steel plate pile joints should be staggered what position?

- Hello, due to site transportation restrictions and insufficient length of existing materials and other reasonsSome projects need to meet the design length by using the site connection method.

- Q: How do you calculate the square footage of a ton of steel?

- The weight of the steel plate is 7.85 tons / cubic meter.The area of 1 ton steel plate (thickness 0.5mm) is: steel plate weight / (steel plate weight * steel plate thickness) =1000/ (7.85*0.5) =254.78 square metersThe total number of steel sheets of 1 tons 1500mm*1800mm*0.5mm specification is 254.78/ (1.5*1.8) =94.36 sheets1500mm*1800mm*0.5mm specification steel plate, each weight is 1.5*1.8*7.85*0.5=10.6 kg

Send your message to us

prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords