AL prepainted roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Corrugated sheet | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

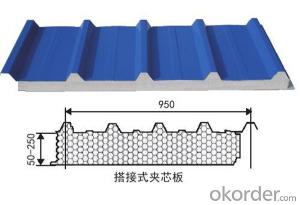

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: Are steel sheets resistant to termites?

- No, steel sheets are not resistant to termites.

- Q: Can steel sheets be used in marine applications?

- Steel sheets are suitable for marine applications, as they possess high strength and durability. This material is widely chosen due to its ability to endure the challenging conditions of saltwater, as well as its resistance to corrosion. In the construction of ships, offshore platforms, and other marine structures, steel sheets are frequently employed to ensure structural integrity. They can be easily customized to meet specific design requirements. Moreover, to enhance their corrosion resistance in saltwater environments, steel sheets can be coated with protective layers like anti-corrosion paints or galvanization. Overall, steel sheets are a dependable and frequently utilized material across various marine applications.

- Q: Are the steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications. Steel is a versatile and durable material that can withstand harsh weather conditions and provide long-term structural support. Steel sheets can be used in various agricultural applications such as constructing farm buildings, barns, sheds, and storage facilities. They can also be used for fencing, roofing, and siding purposes. Steel sheets offer excellent strength and resistance to pests, fire, and rot, making them ideal for protecting agricultural equipment and crops. Additionally, steel is recyclable, which makes it an environmentally-friendly choice for sustainable farming practices. Overall, steel sheets are a reliable and cost-effective solution for various agricultural applications.

- Q: What is the average cost of steel sheets per square foot?

- The average cost of steel sheets per square foot can vary widely depending on various factors such as the type of steel, thickness, size, and market conditions. However, as of 2021, the average cost of steel sheets ranges between $5 to $20 per square foot. It is important to note that this is a general estimate and prices may fluctuate based on location, supplier, and other market factors. Therefore, it is recommended to obtain quotes from multiple suppliers to get an accurate and up-to-date cost for steel sheets per square foot.

- Q: How are steel sheets protected during storage in warehouse facilities?

- Steel sheets are protected during storage in warehouse facilities through various methods to ensure their integrity and prevent damage. One common method is the use of protective coatings or finishes. Prior to storage, steel sheets are often coated with a layer of oil or wax to provide a barrier against moisture and rust. This coating acts as a protective shield, preventing oxidation and corrosion. In addition to coatings, steel sheets are usually stacked and stored in a way that minimizes the risk of physical damage. They are typically placed on pallets or racks, with proper spacing and support to prevent bending or warping. This ensures that the weight is evenly distributed and reduces the risk of deformation. Moreover, warehouse facilities employ various measures to control the environment and protect steel sheets from adverse conditions. For instance, temperature and humidity levels are closely monitored and regulated to prevent moisture buildup, as excessive humidity can accelerate corrosion. Adequate ventilation systems are installed to maintain a dry environment and prevent condensation. Furthermore, warehouse facilities often implement strict security measures to safeguard steel sheets from theft or unauthorized access. These measures may include surveillance cameras, access control systems, and security personnel to prevent any potential damage or loss. Overall, by using protective coatings, proper stacking techniques, controlling the environment, and implementing security measures, warehouse facilities ensure that steel sheets are well-protected during storage, preserving their quality and preventing any potential damage.

- Q: Can steel sheets be used for solar panel frames?

- Yes, steel sheets can be used for solar panel frames. Steel is a commonly used material for solar panel frames due to its strength, durability, and ability to withstand harsh weather conditions. It provides structural support and stability to the solar panels, allowing them to be securely mounted and protected.

- Q: Can steel sheets be used in packaging applications?

- Yes, steel sheets can be used in packaging applications. They are often used for packaging heavy and durable items, providing strength, durability, and protection during transportation and storage.

- Q: How do you store steel sheets to prevent damage?

- To prevent damage while storing steel sheets, it is important to keep them in a dry and well-ventilated area to avoid moisture buildup. Additionally, stacking them horizontally with proper support and using separators such as wooden pallets or rubber mats between each sheet can prevent scratches and dents. Regular inspection for any signs of corrosion or damage is also essential to address any issues promptly.

- Q: What is the average lifespan of steel sheets?

- The average lifespan of steel sheets can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, on average, steel sheets can last anywhere from 20 to 30 years or even longer with proper care and maintenance.

- Q: How do steel sheets perform in terms of noise reduction?

- Steel sheets have excellent noise reduction properties due to their high density and stiffness. They effectively absorb and dampen sound waves, resulting in reduced noise transmission and improved acoustic insulation.

Send your message to us

AL prepainted roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords