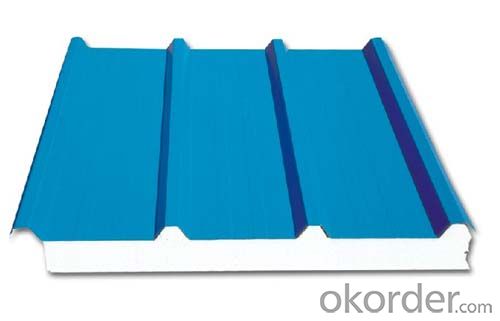

Prepainted steel roof sheet original manufacturer / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: |

| Model Number: | Corrugated sheet |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: How do steel sheets perform in terms of dimensional stability?

- Steel sheets are known for their excellent dimensional stability. This means that they are highly resistant to changes in size or shape when subjected to external forces or fluctuations in temperature. Steel is inherently strong and rigid, allowing it to maintain its shape and dimensions over extended periods of time. Additionally, steel sheets have low thermal expansion coefficients, meaning they expand and contract minimally with changes in temperature. This characteristic further enhances their dimensional stability, making them suitable for applications where precise dimensions and consistent performance are critical. Steel sheets are widely used in various industries, including construction, automotive, and manufacturing, due to their reliable dimensional stability.

- Q: How do steel sheets compare to other materials, such as aluminum or stainless steel?

- Steel sheets have distinct advantages over other materials like aluminum or stainless steel. Steel is known for its exceptional strength and durability, making it an ideal choice for applications that require high structural integrity. Compared to aluminum, steel sheets offer superior tensile strength and resistance to impact, making them more suitable for heavy-duty applications. Stainless steel, on the other hand, provides excellent corrosion resistance, but it may not match the strength of steel. Overall, steel sheets are a versatile material that strikes a balance between strength, durability, and cost-effectiveness, making them a popular choice in various industries.

- Q: What are the different sheet metal folding techniques for steel sheets?

- There are several sheet metal folding techniques that can be used for steel sheets. These techniques are commonly employed in various industries, such as automotive, aerospace, and construction, to create complex shapes and structures. Some of the most common sheet metal folding techniques for steel sheets include: 1. Box and Pan Folding: This technique involves bending the sheet metal along multiple parallel edges to create a box-like shape. It is commonly used to create enclosures, cabinets, and trays. 2. Hemming: Hemming is a technique used to fold the edges of a sheet metal component to increase its rigidity and eliminate sharp edges. It is often used in the automotive industry for creating panels and body parts. 3. Brake Press Folding: A brake press is a machine tool that utilizes a hydraulic or mechanical press to bend the sheet metal. It allows for precise and accurate folding by adjusting the angle and depth of the bend. Brake press folding is one of the most commonly used techniques in sheet metal fabrication. 4. Roll Forming: Roll forming is a continuous bending process where the sheet metal is passed through a series of rollers to gradually shape it into a desired profile. It is suitable for creating long and continuous shapes, such as tubes and channels. 5. Rotary Folding: In rotary folding, a rotating tool is used to fold the sheet metal along a curved or circular path. This technique is often used to create rounded edges, curves, and cylindrical shapes. 6. Folding Machines: Folding machines are specifically designed to fold sheet metal by applying pressure along a predetermined line. These machines can be programmed to perform various folding operations, including simple bends, complex shapes, and multiple folds. Each of these sheet metal folding techniques has its advantages and limitations, and the choice of technique depends on factors such as the complexity of the design, required precision, and production volume. Skilled craftsmen and specialized machinery are often employed to ensure accurate and efficient folding of steel sheets.

- Q: How long do steel sheets last?

- Steel sheets can last for many years, often surpassing the lifespan of other materials. The longevity of steel sheets depends on various factors such as the quality of the steel, the conditions it is exposed to, and how well it is maintained. In general, high-quality steel sheets that are properly installed and maintained can last for several decades or even longer. However, if steel sheets are exposed to harsh environments, such as extreme temperatures, humidity, or corrosive substances, their lifespan may be reduced. Regular inspections, cleaning, and maintenance can help extend the lifespan of steel sheets and ensure their durability over time.

- Q: What is a fixed length steel plate?

- Please check the standard: GB/T706-2008 hot-rolled steel fixed length is in accordance with customer requirements made of length, usually 6 meters, 9 meters look

- Q: What is the average price of steel sheets?

- The average price of steel sheets can vary depending on factors such as size, thickness, and quality. However, as of 2021, the average price range for steel sheets typically falls between $500 and $1,500 per ton.

- Q: Are steel sheets suitable for mining or construction equipment?

- Yes, steel sheets are highly suitable for mining or construction equipment due to their exceptional strength, durability, and resistance to wear and tear. Steel sheets can withstand heavy loads, harsh environments, and rough usage, making them an ideal choice for equipment used in these industries.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are highly resistant to chemical exposure due to their inherent corrosion resistance. The chemical composition and protective coatings on steel sheets make them capable of withstanding a wide range of chemical substances without significant degradation or damage.

- Q: What are the different sheet metal stamping techniques for steel sheets?

- There are several sheet metal stamping techniques for steel sheets, including blanking, piercing, bending, deep drawing, and embossing.

- Q: What are the different testing methods for steel sheets?

- There are several testing methods for steel sheets, including visual inspection, hardness testing, tensile testing, impact testing, bend testing, and ultrasonic testing. Visual inspection involves examining the surface for any visible defects or imperfections. Hardness testing measures the resistance of the steel to indentation, which can indicate its strength and durability. Tensile testing evaluates the steel's ability to withstand pulling forces, while impact testing measures its resistance to sudden shocks or impacts. Bend testing assesses the steel's flexibility and ability to withstand deformation. Ultrasonic testing uses sound waves to detect internal flaws or defects in the steel. These methods are commonly used to ensure the quality and reliability of steel sheets in various industries.

Send your message to us

Prepainted steel roof sheet original manufacturer / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords