Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

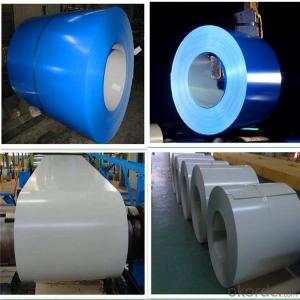

Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

Description of Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the main applications of special steel in the energy storage industry?

- Special steel is extensively used in the energy storage industry for various applications. It is primarily employed in the manufacturing of storage tanks and containers, ensuring the safe storage and transport of energy sources such as liquefied natural gas (LNG) or compressed hydrogen. Special steel is also utilized in the construction of battery casings and components, providing durability and protection for energy storage systems. Additionally, special steel is crucial in the fabrication of critical infrastructure, such as pipelines and transmission towers, which play a vital role in the efficient distribution of energy. Overall, special steel serves as a fundamental material in the energy storage industry, enabling the reliable and secure storage, transportation, and utilization of various energy sources.

- Q: What are the main advantages of using special steel in the marine industry?

- The main advantages of using special steel in the marine industry are its high strength and durability, corrosion resistance, and ability to withstand extreme conditions. Special steel provides the necessary structural integrity to withstand the harsh marine environment, including exposure to saltwater, waves, and impact forces. It also offers excellent resistance to corrosion, which is crucial for maintaining the integrity and longevity of marine structures. Moreover, special steel's ability to withstand extreme temperatures and pressures makes it suitable for various marine applications, such as shipbuilding, offshore structures, and marine equipment.

- Q: What are the main applications of special steel in the power distribution industry?

- Special steel is widely used in the power distribution industry for various applications. One of the main applications is in the construction of transmission towers and electrical pylons. Special steel is preferred for these structures due to its high strength, durability, and resistance to corrosion. It ensures the safe and reliable transmission of electricity over long distances. Special steel is also used in the manufacturing of electrical transformers and generators. The steel's magnetic properties make it suitable for creating efficient and reliable power generation and distribution equipment. Additionally, special steel is used in the production of electrical connectors and conductors, which are essential for ensuring the efficient flow of electricity through power distribution systems. Overall, the main applications of special steel in the power distribution industry include transmission towers, electrical pylons, transformers, generators, and electrical connectors. These applications play a crucial role in maintaining a robust and reliable power grid, ensuring uninterrupted electricity supply to consumers.

- Q: What are the different molding grades of special steel?

- The different molding grades of special steel include tool steel, stainless steel, high-speed steel, and alloy steel.

- Q: Can special steel be used in the renewable energy sector?

- Indeed, the renewable energy sector can effectively utilize special steel. This type of steel, also referred to as alloy steel, offers improved qualities such as exceptional strength, longevity, and resistance to corrosion, rendering it suitable for a diverse range of applications within renewable energy technologies. Within the realm of wind energy, special steel is employed for the production of wind turbine components. Wind turbine towers necessitate materials that are both robust and lightweight in order to withstand the dynamic loads and harsh environmental conditions they encounter. Special steel alloys, including high-strength low-alloy (HSLA) steel, provide the requisite strength-to-weight ratio, thereby ensuring the structural integrity of wind turbine towers. Furthermore, special steel proves advantageous in the field of solar energy. Concentrated solar power (CSP) plants rely on mirrors or lenses to concentrate sunlight, generating intense heat for the purpose of electricity generation. In the construction of these components, special steel alloys possessing high thermal conductivity and the ability to withstand high temperatures are employed. This ensures efficient energy capture and durability. In addition, special steel plays a crucial role in the manufacturing of equipment for hydroelectric power generation. Turbine components, such as blades, shafts, and runners, necessitate materials with exceptional strength and resistance to erosion and cavitation. Special steel alloys, including stainless steel and tool steel, exhibit these characteristics, guaranteeing the longevity and reliability of hydroelectric power systems. In summary, special steel finds widespread application within the renewable energy sector. Its qualities, such as high strength, durability, and resistance to corrosion, make it suitable for use in wind energy, solar energy, and hydroelectric power generation. Through the utilization of special steel, the renewable energy sector can enhance the performance, efficiency, and lifespan of various renewable energy technologies.

- Q: Can special steel be used in the plumbing industry?

- Yes, special steel can be used in the plumbing industry. Special steel, such as stainless steel or alloy steel, offers excellent corrosion resistance and durability, making it suitable for various plumbing applications. It is commonly used in pipes, fittings, valves, and other components that require resistance to chemicals, high pressure, and extreme temperatures.

- Q: How does special steel perform in electrical applications?

- Special steel, known as electrical steel, is purposely created and produced to meet the specific needs of electrical applications. It displays outstanding magnetic properties, rendering it highly suitable for utilization in electrical machines and devices. A primary feature of special steel is its diminished electrical resistivity, enabling efficient current flow and minimizing energy losses in electrical circuits. This reduced resistivity is achieved through precise control of the steel's composition and microstructure. Moreover, special steel possesses a high magnetic permeability, allowing for easy magnetization and demagnetization. This characteristic is crucial for the effective functioning of electrical machines such as transformers, motors, and generators. Additionally, special steel exhibits low coercivity, making it susceptible to magnetization or demagnetization with relatively low levels of magnetic field strength. This attribute proves advantageous in applications requiring rapid and precise magnetic switching, like electric transformers. Furthermore, special steel demonstrates minimal hysteresis loss, which pertains to the dissipation of energy as heat during magnetization and demagnetization cycles. This quality guarantees minimal energy losses in electrical devices, ultimately improving overall efficiency. To summarize, special steel excels in electrical applications due to its low electrical resistivity, high magnetic permeability, low coercivity, and low hysteresis loss. These properties establish it as an ideal choice for a wide range of electrical machines and devices, enhancing their efficiency and reliability.

- Q: What are the challenges in working with special steel?

- When it comes to working with special steel, there are several distinct challenges that set it apart from regular steel. Let's take a look at some of the main difficulties one might encounter in this field: 1. Expensive nature: Special steels often come with higher production costs due to their unique composition and properties. The raw materials used in their production may be scarce or require intricate manufacturing processes, resulting in increased expenses. 2. Limited availability: Special steels are not as readily accessible as regular steels, making it more arduous to source them. This limited availability can lead to longer lead times and potentially higher costs when attempting to obtain the necessary materials. 3. Machining complexity: Special steels can prove challenging to machine due to their elevated hardness or toughness. Their distinctive properties may cause excessive tool wear, resulting in increased machining time and costs. Overcoming these challenges may necessitate the use of specialized cutting tools and machining techniques. 4. Heat treatment requirements: Achieving the desired mechanical properties of special steels often demands precise and specific heat treatment processes. The complexity of heat treatment lies in the careful control of temperature, time, and cooling rates. Improper heat treatment can result in inconsistent material properties or even material failure. 5. Welding difficulties: In comparison to regular steels, certain special steels may exhibit poor weldability. They may be prone to cracking or require preheating and post-weld heat treatment to ensure proper joint integrity. This can introduce complexity and cost to welding processes. 6. Corrosion susceptibility: While special steels may possess excellent mechanical properties, they can sometimes be more vulnerable to corrosion when compared to regular steels. This necessitates additional measures to protect the steel from corrosion, such as applying protective coatings or utilizing corrosion-resistant alloys. 7. Knowledge and expertise requirements: Working with special steels typically demands a higher level of technical knowledge and expertise. The unique properties and characteristics of these materials necessitate a deep understanding of their behavior and effective handling. This may call for specialized training or collaboration with experts in the field. Despite these challenges, working with special steel also offers various benefits, including superior strength, durability, and performance in specific applications. By comprehending and addressing these challenges, engineers and manufacturers can leverage the unique properties of special steel to develop innovative and high-quality products.

- Q: Can special steel be used in the defense industry?

- Yes, special steel can be used in the defense industry. Special steel, such as high-strength steel or armor-grade steel, possesses unique properties that make it suitable for various defense applications. It can be used for manufacturing military vehicles, aircraft components, body armor, ballistic plates, and other defense equipment that require enhanced strength, durability, and resistance to extreme conditions. Special steel's ability to withstand impacts, provide protection against projectiles, and maintain structural integrity makes it an essential material in the defense industry.

- Q: What are the different high-pressure grades of special steel?

- There exist several distinct varieties of special steel that are designed to withstand high pressures, each possessing its own unique characteristics and uses. Some frequently employed high-pressure grades of special steel encompass the following: 1. 4130 steel: This particular grade of steel is renowned for its exceptional strength, toughness, and resistance to heat. It finds considerable application in the fabrication of high-pressure tubing and components for the oil and gas industry. 2. 4340 steel: Distinguished by its extraordinary strength and toughness, this grade of steel is commonly utilized in the production of critical components like high-pressure valves, gears, and other crucial parts in industries such as aerospace, defense, and automotive. 3. 316 stainless steel: Highly resistant to corrosion and boasting excellent high-temperature properties, this stainless steel grade is frequently employed in high-pressure scenarios like pipelines, heat exchangers, and pressure vessels within the chemical and petrochemical industries. 4. 17-4 PH stainless steel: Offering a combination of high strength, superb corrosion resistance, and good toughness, this stainless steel grade often finds application in high-pressure pump components, turbine blades, and other vital parts within industries like power generation and aerospace. 5. F22 steel: Classified as a low-alloy steel with remarkable high-temperature strength and exceptional resistance to creep, this grade of steel is commonly used in high-pressure and high-temperature environments such as boilers, pressure vessels, and piping systems found in power plants and refineries. The aforementioned examples represent just a small selection of the available high-pressure grades of special steel. The appropriate grade choice is contingent upon the specific requirements of the application, encompassing factors such as pressure, temperature, corrosion resistance, and mechanical properties.

Send your message to us

Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords