Wood pattern PPGI PPGL Prepainted steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

colour coated steel

painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.5mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price | Our Customers | Steel force, Stemcor, Duferco, Samsung , G&G,Hyosung,CNBM |

Packaging & Delivery

Packaging Detail: | standard export packing or customized |

Delivery Detail: | 15 days after prepayment |

Specifications:

galvanized steel coil:

1.Thickness:0.17mm-1.5mm

2.Zinc coated:40g-275g/2

3.Standard:dx51d+z,sgcc

We manufacture Galvanized Steel Coils,Pre-painted Galvanized Steel Coils , etc

Prepainted steel coil features:

1. Zinc coating :40-120g(as reauired)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

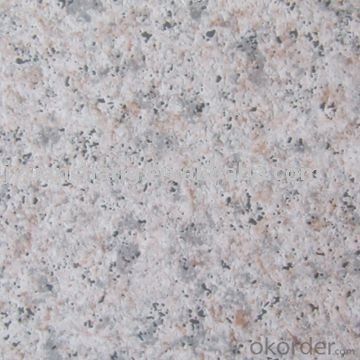

6. surface treatment:RAL color

Galvanized steel coil features:

1. Zinc coating :40-275g( as required)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment: cremated, oiled, skin passed

7. Spangle: regular,small, zero

8.Application: With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product name | steel coil,galvanized steel,galvanized steel coil |

Material | DX51D, SGCC, SPCC, CGCC, DX51D |

Normal thickness | 0.17-1.2mm |

Normal width | 900mm,914mm, 1000mm, 1200mm, 1220mm, 1250mm |

Coil weight | 3-12ns |

Certificate | BV & SGS |

Original | Shandong,China |

Payment terms | L/C or T/T |

Delivery time | within 15 ~ 25 days after 30% prepayment |

- Q: How are steel strips used in the production of agricultural implements?

- Steel strips are used in the production of agricultural implements as they provide strength and durability to the implements. These strips are commonly used for creating blades, tines, and other parts that need to withstand the harsh conditions of farming activities. Steel strips also allow for precise shaping and cutting, ensuring that the agricultural implements are efficient and effective in their intended use.

- Q: How are steel strips tested for edge condition?

- Steel strips are tested for edge condition by conducting visual inspections, measuring the edge burr, and checking for any cracks or deformations. Additionally, various mechanical tests such as bending, flattening, and hardness tests may be performed to ensure the desired edge quality of the steel strips.

- Q: How do steel strips contribute to product aesthetics in various applications?

- The utilization of steel strips in different applications can have a significant impact on the aesthetics of products. Firstly, the sleek and modern touch provided by steel strips can enhance the overall appearance of a product. The polished and sophisticated look achieved through the smooth and reflective surface of steel is visually appealing to customers. Secondly, the manipulation and formation of steel strips into various shapes and patterns allow for greater design flexibility. This versatility enables manufacturers to create unique and eye-catching designs that differentiate their products from competitors. Steel strips can be customized to meet specific aesthetic requirements, whether for decorative purposes or functional elements. Additionally, the aesthetics of a product can be further enhanced by coating or treating steel strips with different finishes. For instance, the application of colored finishes or protective coatings adds visual interest and durability. The range of available finishes allows designers to achieve different visual effects and textures, resulting in a distinctive and appealing appearance for products. Moreover, steel strips can be combined with other materials to create captivating contrasts or combinations in terms of colors, textures, and finishes. This integration leads to visually striking and harmonious designs that appeal to the senses and emotions of consumers. Lastly, the durability and longevity of steel strips are crucial factors in product aesthetics. By utilizing steel strips, manufacturers can ensure that their products maintain their appearance and functionality over time, contributing to a positive perception of the product's aesthetics. Overall, steel strips offer a multitude of aesthetic possibilities in various applications. Their sleek appearance, design versatility, customizable finishes, compatibility with other materials, and durability all contribute to enhancing the overall aesthetics of products.

- Q: How are steel strips embossed or patterned?

- Steel strips can be embossed or patterned through various techniques. One common method is through the use of embossing rolls or dies. These rolls or dies are engraved with specific patterns or designs, which are then pressed onto the steel strip under high pressure. This process creates raised or recessed areas on the surface of the strip, resulting in the desired pattern or design. Another technique used is called laser engraving. In this method, a laser beam is directed onto the steel strip, selectively removing material to create the desired pattern. This process allows for intricate and precise designs to be achieved. Additionally, steel strips can also be patterned using chemical etching. A resist material is applied to the surface of the strip, protecting certain areas from the etching solution. The strip is then immersed in the etching solution, which selectively removes material from the unprotected areas, resulting in the desired pattern. Overall, steel strips can be embossed or patterned using a variety of techniques such as embossing rolls or dies, laser engraving, and chemical etching. These methods offer flexibility in design options and can create visually appealing and functional patterns on steel strips.

- Q: How are steel strips tested for non-destructive evaluation?

- Various techniques are commonly employed to assess the quality and integrity of steel strips without causing damage. One widely used technique is ultrasonic testing (UT), which involves transmitting high-frequency sound waves into the strip and analyzing the reflected waves to identify any defects or inconsistencies. During UT, a transducer is placed on the strip's surface to emit ultrasonic waves that travel through the material. When these waves encounter changes in the strip, such as cracks, voids, or thickness variations, they reflect back. The reflected waves are then received by the transducer and converted into electrical signals. These signals are subsequently analyzed by a computer or an operator to determine the presence, location, and size of any defects. Another commonly employed method for evaluating steel strips is magnetic particle inspection (MPI). In this technique, the strip is magnetized, and magnetic particles are applied to its surface. If there are any surface or near-surface defects, like cracks or discontinuities, the magnetic particles are attracted to these areas, making the defects visible for inspection. Eddy current testing (ECT) is another non-destructive evaluation technique used for steel strips. It involves passing an alternating current through a coil, which generates a magnetic field. When the coil is placed near the strip, any variations in the electromagnetic field caused by defects or material changes induce eddy currents in the strip. These eddy currents generate their own magnetic field, which can be detected and analyzed to identify defects in the material. In addition, visual inspection is frequently conducted to assess the surface condition of steel strips. This entails carefully examining the strip for visible defects such as scratches, dents, or corrosion. In conclusion, non-destructive evaluation techniques such as ultrasonic testing, magnetic particle inspection, eddy current testing, and visual inspection are employed to test steel strips for defects or inconsistencies. These methods ensure the quality and reliability of the strips without causing any damage.

- Q: How are steel strips tempered?

- Steel strips are tempered by heating them to a specific temperature and then rapidly cooling them. This process helps to reduce the brittleness of the steel and improves its toughness and flexibility.

- Q: How do steel strips perform in terms of heat resistance?

- Steel strips generally have good heat resistance due to their high melting point and good thermal conductivity. They can withstand high temperatures without deformation or damage. However, the specific heat resistance of steel strips can vary depending on the type of steel and its composition.

- Q: Are steel strips suitable for the production of cutting tools?

- Yes, steel strips are suitable for the production of cutting tools. Steel strips are known for their high strength, durability, and excellent hardness properties, making them ideal for creating sharp and long-lasting cutting edges. Additionally, steel strips can be easily shaped, heat-treated, and finished to meet the specific requirements of different cutting applications. With their versatility and reliability, steel strips are a popular choice in the manufacturing of various cutting tools such as knives, saw blades, and shears.

- Q: How do steel strips contribute to product recyclability in various applications?

- Steel strips contribute to product recyclability in various applications by being easily and efficiently recycled themselves. They can be melted down and reused multiple times without losing their properties or quality. This not only reduces the need for virgin steel production, conserving natural resources, but also minimizes waste generation and energy consumption. Additionally, the versatility and strength of steel strips make them suitable for a wide range of applications, further enhancing their recyclability across industries.

- Q: How are steel strips used in the automotive supply chain?

- Steel strips are used in the automotive supply chain for a variety of purposes, including manufacturing various components of vehicles such as body panels, chassis, and suspension parts. These strips are often formed, cut, and welded to create the desired shapes and sizes required for specific automotive applications. Additionally, steel strips are also used in the production of automotive springs, exhaust systems, and other essential components, making them a crucial material in the automotive manufacturing process.

Send your message to us

Wood pattern PPGI PPGL Prepainted steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords