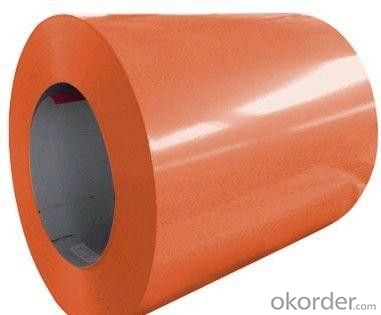

Prepainted steel coils, Hot-dipped Galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ppgl steel coil

Thickness: 0.15-0.6mm

Width:600-1250mm

Color:all Ral color

Hardness: Soft to full hard

Applications

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

1.PPGL Steel information

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Galvanized steel coils, |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-15days after signing contract |

Price | FOB&CNF&CIF price |

Payment terms | TT or L/C |

Monthly supply | 30000MT per month |

Application: | workshop, storeroom, roofing,kiosk... |

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils include conducting visual inspections to check for surface defects, such as scratches, dents, or discoloration. Measurements are taken to ensure the proper dimensions and thickness of the steel coil. Mechanical properties, such as tensile strength and yield strength, are also tested to ensure they meet the required standards. Additionally, tests may be performed to check for coatings, such as zinc or paint, to ensure they are applied correctly and adhere properly to the steel surface.

- Q: How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through a variety of methods. One common method is the application of a protective coating or film on the surface of the coils. This coating acts as a barrier, preventing direct contact between the steel surface and any potential sources of scratches or damage. The protective coating can be made of materials like polyethylene, PVC, or other types of plastic that are resistant to abrasion and impact. Additionally, steel coils are often wrapped or packaged using materials such as paper, cardboard, or plastic. This wrapping provides an extra layer of protection against scratches and damage during storage, transportation, and handling. The wrapping material acts as a cushion, absorbing any potential impacts or friction that could lead to scratches. Furthermore, steel coils may be stored and transported in specially designed containers or pallets that are equipped with features to minimize the risk of damage. For instance, these containers or pallets may have padded interiors, secure fastenings, or dividers that keep the coils in place and prevent them from rubbing against each other. In some cases, steel coils are also stored or transported in a controlled environment to minimize the risk of damage. This can include temperature-controlled warehouses or shipping containers that help to prevent the formation of moisture, which can lead to corrosion or other types of damage. Overall, a combination of protective coatings, wrapping materials, specialized containers, and controlled environments is employed to ensure that steel coils are adequately protected against scratches and damage throughout their lifecycle.

- Q: Can steel coils be coated with luminescent materials?

- Yes, steel coils can be coated with luminescent materials.

- Q: What is the lifespan of coated steel coils?

- The lifespan of coated steel coils can vary depending on various factors such as the type and quality of the coating, the environmental conditions it is exposed to, and the maintenance and care provided. Generally, high-quality coated steel coils can have a lifespan of 25 to 50 years or even more. However, it is important to note that this is just an estimate and the actual lifespan may vary. Regular inspections, proper installation, and timely maintenance can significantly extend the lifespan of coated steel coils. Additionally, factors such as exposure to harsh weather conditions, corrosive environments, and improper handling can potentially shorten the lifespan. It is recommended to consult with manufacturers or industry experts to determine the most suitable coating and expected lifespan for specific applications.

- Q: How are steel coils inspected for quality control?

- Steel coils are inspected for quality control through various methods. One common method is visual inspection, where trained professionals visually examine the coils for any surface defects, such as scratches, dents, or discoloration. Additionally, non-destructive testing techniques like ultrasonic testing are used to detect any internal defects, such as cracks or voids. Dimensional measurements are also taken to ensure the coils meet the required size and thickness specifications. These comprehensive inspections help ensure the overall quality and integrity of steel coils before they are used in various industries.

- Q: What are the main steel coil producing countries?

- The main steel coil producing countries are China, Japan, India, the United States, and Russia.

- Q: Can steel coils be rewound?

- Yes, steel coils can be rewound.

- Q: How are steel coils used in the production of industrial shelving?

- Steel coils are used in the production of industrial shelving by being transformed into steel sheets or strips, which are then cut, formed, and assembled to create the shelves. The coils provide the necessary raw material for manufacturing sturdy and durable shelving units that can support heavy loads in industrial settings.

- Q: Is there a chemical that can be applied (spraid, brushed, adhere) to a steel surface to decrease the heat conductive properties of the metal (so it doesn't heat up as quickly)?Thanks in advance!

- There is, but I don't know what it is made out of. It is probably some fireproof, foam material which acts like insulation. I doubt it is designed to resist abrasion however. Most things which adhere to metal surfaces are not flameproof, and those which do resist fire are not good insulators. For example, the ceramic coating of appliances like stoves and washing machines adhere very well and are fire resistant, but do not insulate. It was the failure of the steel insulation which caused the collapse of the world trade centers. The impact of the airplane tore away all the insulation on the supporting struts of the building and then the fire caused the steel to soften and break. Steel was once insulated by wrapping it in asbestos cloth and then applying plaster over this to form a shell. It did not actually adhere to the steel but it did insulate it, and was fireproof. However asbestos is a cancer hazard and a lot of old buildings are being stripped of their asbestos as a safety precaution. The asbestos can be replaced with fiberglass which is usually duct taped together.

- Q: What are the common welding defects in steel coils?

- During the welding process, various defects can occur in steel coils. These defects encompass: 1. Porosity: Gas entrapment during welding results in small holes or voids in the weld metal. This defect weakens the weld and increases its vulnerability to corrosion. 2. Insufficient fusion or incomplete penetration: Inadequate fusion between the base metal and weld metal or incomplete penetration of the joint leads to this defect. A weak or brittle weld is the consequence. 3. Cracks: Cracks can manifest in the weld metal or the heat-affected zone (HAZ) of the base metal. They are caused by factors like high stress levels, improper cooling, or insufficient preheating. Cracks significantly reduce the weld's strength and integrity. 4. Undercutting: Excessive melting of the base metal at the weld's toe creates a groove or depression known as undercutting. This defect weakens the weld and concentrates stress, potentially leading to failure. 5. Excessive spatter: The welding arc expels small droplets of molten metal, which can land on the steel coil's surface. Too much spatter results in a rough or uneven surface finish and necessitates additional cleaning or grinding. To minimize these welding defects in steel coils, it is vital to ensure proper weld preparation, including thorough cleaning to remove any contaminants from the steel's surface. Moreover, utilizing the correct welding parameters, such as appropriate heat input and travel speed, helps minimize defects. Regular inspection and quality control measures also aid in detecting and addressing defects before they escalate into more serious issues.

Send your message to us

Prepainted steel coils, Hot-dipped Galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords