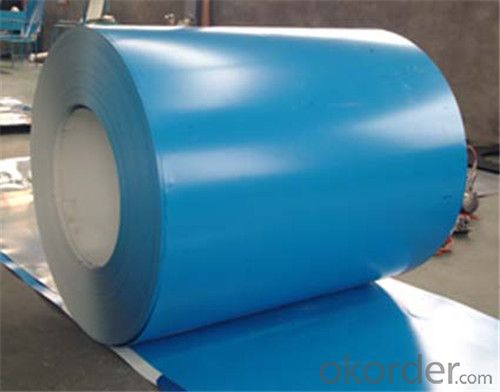

Prepainted Steel Coils, Hot-dipped Galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coil

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate,

through the surface pretreatment (degreasing, cleaning, chemical conversion

processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling.

SPECIFICATION

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

2.Grade: DX51D+Z, DC51D, SPCC, SGCC, SGHC, CGCC,

3.Surface Treatment Coated: Galvanized, Paint sealant, Coating passivation solution

Substrate Cold rolled, Galvanized sheet

4.Color: RAL Color card

5.Coil ID: 508/610 mm

6.Coil weight: 4-10MT

7.Paint film Front side: 10~25um

Back side: 5~10um

8.Zinc layer: 40~180g per square meter

9.Thickness: 0.125~1.3mm

10.Width: 600~1250mm

11.Length: As requirement

12.Type: Steel plate, Steel Coil, Roofing metal

13.Place of origin: Shandong CHINA(mainland)

14.Deliver time: 20-30 days after receipt of advanced t/t or L/C

Advantages

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3.Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and

autonomous regions, and have been exported to Europe, North American, the Middle East,

the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

| commodity | prepained Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.125-1.3mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z40-180g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-10 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

- Q: What are some characteristics of steel.

- Characteristics Of Steel Hardening. - The characteristic difference between steel and pure wrought iron is as follows: - When steel is raised to a red heat and then suddenly cooled, it becomes hard and brittle. This process, which is known as hardening, has no effect upon pure wrought iron. Tempering is a characteristic of steel which distinguishes it from cast iron. If steel has been hardened by being heated and suddenly cooled, as above described, it may be softened again by applying a lower degree of heat and again cooling. This is known as tempering. Cast iron, on the contrary, though it is hardened by the first process, cannot be softened by the second. When a bar of steel is struck it gives out a sharp metallic ring, quite different from the sound produced by striking wrought iron. Other characteristics of steel are its great elasticity and its retention of magnetism.

- Q: How are steel coils inspected for surface quality?

- To ensure that steel coils meet the required standards and are defect-free, a meticulous inspection process is carried out using various methods and technologies. The following steps are involved in inspecting the surface quality of steel coils: 1. Visual Inspection: Trained personnel visually examine the entire surface of the coils to detect any visible defects such as scratches, dents, or irregularities. This step allows for the identification of obvious issues through visual observation. 2. Magnetic Particle Inspection: This non-destructive testing method involves applying a magnetic field to the surface of the steel coil and then adding a magnetic particle solution. Any surface cracks or defects cause the magnetic particles to cluster, making them visible under appropriate lighting. This technique effectively detects surface cracks and abnormalities. 3. Eddy Current Testing: Electromagnetic induction is used in this inspection method to identify surface defects. An eddy current probe is moved over the surface of the steel coil, and any variations in the electrical current induced by the magnetic field are detected. This technique is especially useful for detecting surface cracks, pits, or corrosion. 4. Ultrasonic Testing: Ultrasonic waves are employed to inspect the surface of the steel coil for hidden defects like subsurface cracks or inclusions. High-frequency sound waves are transmitted into the material, and any changes in the reflected sound wave pattern indicate the presence of defects. Ultrasonic testing is highly reliable and can detect even the smallest defects within the steel coil. 5. Surface Roughness Measurement: Specialized equipment is used to measure the surface roughness of the steel coil. This measurement helps determine if the surface meets the required smoothness standards. The equipment scans the surface and provides detailed information about the roughness, allowing the inspector to ensure it falls within an acceptable range. In summary, the inspection of steel coils for surface quality involves a comprehensive process that combines visual examination with advanced testing methods such as magnetic particle inspection, eddy current testing, ultrasonic testing, and surface roughness measurement. These inspection techniques effectively identify and evaluate potential defects or surface irregularities, ensuring that the steel coils meet the necessary surface quality standards.

- Q: In construction, what types of stress require steel to be placed in footings?

- Bending moment , shear stress and punching stresses

- Q: What metals contain steel? It can be anything except soft iron or steel.

- tricky situation. look from google. it may help!

- Q: What are the common applications of coated steel coils?

- Some common applications of coated steel coils include manufacturing of automotive parts, construction materials such as roofing and siding, appliances, and electrical equipment. They are also used in the production of household goods such as furniture, shelving, and storage racks. Additionally, coated steel coils find applications in the transportation industry for manufacturing trailers, shipping containers, and railway cars due to their durability and corrosion resistance.

- Q: doesnt steel rust?

- Iron mixed with other metals:

- Q: How are steel coils used in the production of steel locks?

- Steel coils are used in the production of steel locks as they are rolled into sheets and then cut into appropriate sizes to form the body and components of the locks. The coils provide a consistent and high-quality raw material that can be easily shaped and transformed into the desired lock designs, ensuring durability and strength in the final product.

- Q: What are the different methods of forming steel coils?

- Steel coils can be formed using several methods, depending on their specific requirements and applications. These methods comprise hot rolling, cold rolling, and continuous casting. The most commonly used method for forming steel coils is hot rolling. This involves heating the steel billet or ingot to high temperatures and passing it between a series of rollers to reduce its thickness and shape it into a coil. Typically, this process is carried out above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. On the other hand, cold rolling is performed at or near room temperature. It entails passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often utilized to produce steel coils with precise dimensions and excellent surface finish. Additionally, it can enhance the strength and hardness of the steel. Another method for forming steel coils is continuous casting. This involves pouring molten steel into a continuous casting machine, where it solidifies into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, including improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These processes encompass pickling, annealing, and coating. Pickling is used to remove any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which improves its ductility and reduces internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. To summarize, steel coils can be formed using different methods such as hot rolling, cold rolling, and continuous casting. Each method offers distinct advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes like pickling, annealing, and coating are employed to further enhance the quality and performance of the steel coils.

- Q: What are the different methods of coil recoiling for narrow strip widths?

- Some of the different methods of coil recoiling for narrow strip widths include slitting and rewinding, oscillating winding, and turret winding.

- Q: How are steel coils used in the manufacturing of automotive suspension systems?

- Steel coils are used in the manufacturing of automotive suspension systems as they provide the necessary support and stability to withstand the weight and movement of the vehicle. These coils are typically shaped into springs and installed in the suspension system to absorb shocks, maintain proper ride height, and improve overall handling and comfort for the driver and passengers.

Send your message to us

Prepainted Steel Coils, Hot-dipped Galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords