Prepainted steel coils -Any color you want

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,JIS | Grade: | steel | Thickness: | 0.17-1.5mm |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | SGCC Q195L, Q235, DX51D |

| Type: | Steel Coil | Technique: | Hot Rolled,hot dip | Surface Treatment: | Coated |

| Application: | Flange Plate | Special Use: | Steel | Width: | 600-1250mm |

| Length: | 2000-6000mm |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

Our Advantages

1. more than 10 years experiences in steel business

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

7. long mutual beneficial business cooperation

8. certificate: ISO9001

| Commodity | Prepanited steel coil |

| Grade | JIS G3302(SGCC), DX51D, EN10142, GB/T2518-2004, ASTM 653 |

| Standard | ASTM, AISI, DIN, GB |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.16-1.2mm (0.14-0.5mm is the most advantage thickness) |

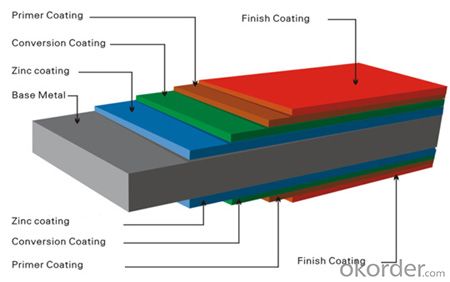

| Type of coating | Galvanized |

| Zinc / PE coating | Z60-275g/m2 ,12-20μm(top)/7-10μm(bottom) |

| Surface | RAL System as per customers request |

| ID coil | 508mm |

| Coil weight | 4-6MT |

| Package | Properly packed for ocean freight exportation |

| Application | Industrial panels, roofing and siding for painting |

| Payment terms | 30%TT in advance+70% TT or irrevocable 100%L/C at sight |

| Delivery time | 25 days after recepit of 30% TT or L/C |

PACKING

4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection

FAQ

We have organized several common questions for our clients,may help you sincerely:

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

In the purchase of product within 20-25 days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 30 days can be served.

3)Do you have necessary certificate or inspection to make sure we can import smoothly?

Syringes are CE,FDA approved. And we supplied main nations in the world.

- Q: A song by brokencyde is called Blue Steel.... a verse in it says Don't make me show you blue steel.

- Reference is to a gun which is typically the process of Bluing the steel of the guns metal parts.

- Q: What are the different types of steel coil edge finishes?

- There are several types of steel coil edge finishes, including mill edge, slit edge, round edge, and deburred edge.

- Q: How do steel coils compare to other materials like aluminum or copper?

- When comparing steel coils to other materials like aluminum or copper, it is evident that they possess both advantages and disadvantages. One primary advantage of steel coils lies in their remarkable strength and durability. Steel is renowned for its high tensile strength, enabling it to withstand heavy loads and high stress without any deformation. As a result, steel coils are highly suitable for various applications that demand robust and resilient materials, including construction, automotive manufacturing, and transportation industries. In contrast, aluminum and copper are generally softer and less strong than steel, rendering them less appropriate for heavy-duty tasks. Another advantage of steel coils is their cost-effectiveness. In comparison to aluminum or copper, steel is a relatively inexpensive material, making it a more accessible option for large-scale projects or mass production. Furthermore, steel is highly recyclable, contributing to its cost-effectiveness and sustainability. Nonetheless, steel coils do have some disadvantages when compared to aluminum or copper. One notable drawback is their weight. Steel is significantly denser than aluminum or copper, resulting in heavier steel coils that can be more challenging to handle and transport. This disadvantage can prove to be critical in industries where weight plays a vital role, such as aerospace or electrical applications. Additionally, steel coils are susceptible to corrosion, which is another disadvantage. While aluminum and copper possess natural corrosion resistance, steel is prone to rust and oxidation. Consequently, steel coils require proper protection and coating to prevent corrosion, which adds to the overall cost and maintenance requirements. In conclusion, steel coils offer exceptional strength, durability, and cost-effectiveness when compared to aluminum or copper. However, they are generally heavier and more prone to corrosion. Ultimately, the selection between steel, aluminum, or copper will depend on the specific application, budget, and project requirements.

- Q: How are steel coils processed before they are used in manufacturing?

- Steel coils undergo several processing steps before they are used in manufacturing. The first step is called pickling, where the coils are immersed in an acid bath to remove any surface impurities, such as rust or scale. This helps to improve the surface quality of the steel. After pickling, the coils go through a process called cold rolling. This involves passing the coils through a series of rollers to reduce their thickness and improve their dimensional accuracy. Cold rolling also enhances the mechanical properties of the steel, making it stronger and more durable. Next, the coils are annealed, which involves heating them to a specific temperature and then slowly cooling them. Annealing helps to relieve internal stresses in the steel and improves its formability and ductility. Following the annealing process, the coils may undergo additional surface treatments, such as galvanizing or coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion, while coating can involve applying various types of paint or polymer to enhance the steel's appearance or provide specific functionalities. Once the coils have been processed and treated, they are typically cut into smaller sheets or strips, depending on the manufacturing requirements. These sheets or strips can then be used in various manufacturing processes, such as stamping, forming, welding, or fabrication, to create a wide range of products, including automotive components, appliances, construction materials, and many others. In conclusion, steel coils undergo a series of processing steps, including pickling, cold rolling, annealing, and surface treatments, before they are ready to be used in manufacturing. These processes improve the quality, strength, and formability of the steel, allowing it to be transformed into a variety of products.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped. Steel coils are highly flexible and can undergo various bending and shaping processes to achieve desired forms and configurations.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- I would get a 1095, serrated edge, tanto style, with either a good quality rubberized or bone handle.

- Q: I am a beginner and have a slow to average swing speed. Should i get graphite or steel shafts for my irons and does it make a difference?

- I agree with Matt C. I owned both steel shafted and graphite shafted irons (Callaway BB 06 Graphite and Taylor Made R7 Draw Steel). My club head speed is 75 to 80 mph. I switch to steel to graphite because i gain yards at least 15 to 20 yards more. My 9 iron (graphite) is a 150 club and my 7 iron in steel shafted. So my advice is to try both and see which one is best suited for you.

- Q: How are steel coils used in the production of telecommunications equipment?

- Steel coils are commonly used in the production of telecommunications equipment as they provide structural support and durability. These coils are used to create various components of telecommunications equipment, such as cabinets, racks, and enclosures. One important application of steel coils in telecommunications equipment is the manufacturing of cabinets. These cabinets house the sensitive electronic components and wiring used in telecommunications systems. Steel coils are typically formed and shaped to create the structure of these cabinets, providing a sturdy and reliable housing for the equipment. The steel material also provides protection against external factors like impacts, dust, and moisture, ensuring the longevity and integrity of the telecommunications equipment. Steel coils are also utilized in the production of racks for telecommunications equipment. These racks are designed to hold multiple pieces of equipment, such as servers, switches, and routers, in an organized and accessible manner. The strength and rigidity of steel coils make them an ideal material for constructing these racks, ensuring that they can bear the weight of multiple devices and withstand the constant handling and movement that occurs in telecommunication environments. Furthermore, steel coils are used to manufacture enclosures for telecommunications equipment. Enclosures are protective casings that shield sensitive electronic components from external influences like electromagnetic interference and physical damage. Steel coils are often formed into specific shapes and sizes to create these enclosures, providing a robust barrier that safeguards the equipment from various external threats. In summary, steel coils play a crucial role in the production of telecommunications equipment by providing structural support, durability, and protection. They are used to create cabinets, racks, and enclosures, which ensure the proper functioning and longevity of the sensitive electronic components used in telecommunication systems.

- Q: How are steel coils used in the production of electrical resistors?

- Steel coils are used in the production of electrical resistors as they provide a conductive path for the flow of electric current. The resistance of the coil is determined by its length, thickness, and material properties, allowing it to regulate the flow of electricity in various applications such as heating elements and electronic circuits.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications. They are utilized in the manufacturing of pipelines, storage tanks, and other equipment due to their strength, durability, and resistance to corrosion. Steel coils are also employed in the construction of offshore platforms and drilling rigs, where they provide structural support and ensure the safety and reliability of the infrastructure.

Send your message to us

Prepainted steel coils -Any color you want

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords