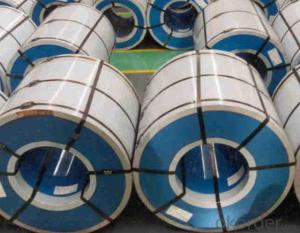

prepainted steel coil from steel manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | Q235,SS400,Q215,Q195,SPCC | Thickness: | 0.14MM TO 0.8MM |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | COIL |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | NEGOTIATED | Special Use: | High-strength Steel Plate | Width: | 10MM TO 1500MM |

| Length: | 10MM TO 1500MM |

Packaging & Delivery

| Packaging Detail: | COIL, wood or steel pallets wit plastic film, professional exporting seaworthy package, load by container or breakbulk vessel or according to customers' requirement . |

| Delivery Detail: | 1 MONTH |

Specifications

PPGI/Prepainted steel coil

Thickness: 0.14-0.80mm

Width:600-1250mm ,Znic:50-180g/M2

Colour:20-25um

Certificate:ISO9001:2000

Specifications

PPGI / prepainted steel coil

high quality and good price

PPGI / prepainted steel coil

1.Production details:

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

Manufacturer | Thickness | Width | Length of plate | Inner diameter of coil |

CNBM | 0.2-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: How do steel coils contribute to acoustic performance in buildings?

- Steel coils can contribute to acoustic performance in buildings by providing sound insulation and reducing noise transmission. When installed as part of a building's structure, steel coils can help absorb and dampen sound vibrations, preventing them from traveling through walls and floors. This can result in a quieter and more comfortable indoor environment, minimizing disruptions and enhancing overall acoustic quality within the building.

- Q: How many pounds can steel lift?

- It depends on the type of steel and the geometry of the item.

- Q: I am working on a hydrogen generator, but the stainless steel I am using corrodes and turns the water brown. Can anyone tell me if there is stainless steel that does not corrode, and if so, what is it called and where can I get some.Thank you.

- All stainless steel will corrode in certain conditions. Some varieties are worse than others. For instance grade 409 which is used for car exhausts (and other things) will rust. For the most suitable grade call a local steel supplier which carries stainless steel. Some of these companies will have a catalog of available grades and the appropriate uses. It would probably help to let them know what types of chemicals are present and what temperature the water is. You may want to call several suppliers, the quality of answer you get may vary quite a bit from company to company. The cost of exotic grades of stainless can be quite high. you may have to use a less appropriate grade if you can't justify the cost. If corrosion is a very serious concern for this be forewarned that stainless steels can be contaminated by contact with carbon steel (ordinary steel). I have seen rust form on stainless steel after a carbon steel bar was set down on the stainless steel. The carbon steel will leave trace amounts under prolonged contact. I have even seen signs of contamination of stainless steel direct from the supplier.

- Q: full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

- Q: im writing a book.-how is steel made? like, from what natural resources?-is there a type of factory that just prouduces steel to then be made into the various things made out of steel? if so, what kind of company might that be?-what is the first stage of steel, like, right after the other....ingrediants......are mixed, but before it is shaped into whatever its destined to be?thank you so much, i really appreciate it!

- Iron and Carbon, mostly. It can include Manganese, Chromium, Vanadium, Tungsten, and a couple of others, depending on what it will be used for.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are various coil packaging machine configurations utilized for steel coils, each tailored to specific coil sizes, weights, and packaging needs. 1. The horizontal coil packaging machine is designed for smaller steel coils. It is typically equipped with a conveyor system that transports the coil horizontally throughout the packaging process. It may incorporate automatic coil centering, wrapping, and strapping features to guarantee secure and efficient packaging. 2. The vertical coil packaging machine is suitable for larger and heavier steel coils. It is designed to package coils in a vertical position and often includes a rotating arm or turntable for wrapping and securing the coil with strapping. Vertical machines have a higher throughput capacity and can handle coils of various sizes and weights. 3. The ring coil packaging machine is specifically designed for large and heavy steel coils. It comprises a rotating ring structure that surrounds the coil and moves up and down while wrapping and securing it with stretch film or other packaging material. Ring coil packaging machines are versatile, accommodating coils of different diameters and weights, making them suitable for various coil packaging requirements. 4. The eye-to-sky coil packaging machine is intended for steel coils that need to be packaged in an eye-to-sky orientation. It typically features a wrapping station that rotates the coil while applying stretch film or other packaging material. This configuration ensures proper protection and stability during transportation and storage. 5. The eye-to-horizontal coil packaging machine is designed for steel coils that need to be packaged in an eye-to-horizontal orientation. It includes a conveyor system that transports the coil horizontally while applying stretch film or other packaging material. Eye-to-horizontal machines can handle coils of different sizes and are designed to provide secure packaging for easy handling. In conclusion, the choice of coil packaging machine configuration depends on factors such as coil size, weight, packaging requirements, and production throughput. Different configurations offer distinct features and capabilities to ensure efficient and secure packaging of steel coils.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- Most of the parts are cut, welded, and fabricated indoors in a welding shop at another location. Then they're trucked to the site and simply need to be bolted together. This is made possible through the use of computer aided design and modeling programs, so that parts can be made to fit almost presciently in the field. They buy the steel from steel companies. I couldn't tell you exactly where it comes from, you'd have to ask the contractors themselves.

- Q: What other metal is used to make rings? My girlfriend is allergic to stainless steel, but she wears a silver/grayish color ring, but I'm not sure what metal it is. Any ideas? Thanks!

- Silver, white gold and titanium are quite common.

- Q: Can steel and/or stainless steel turn rusty ?

- Stainless is an alloy mixture the contains iron and nickel and does not rust.

- Q: I want to replace the old refrigator within the next 6 months........ Is the trend to buy a stainless steel refrigerator? Some magazines and internet sites are pointing me that direction. What are the pro's and con's ? I like the color bisque, or cream-color as well, or better, than stainless steel. What would be the reasons to buy stainless steel...is it becoming the most popular color ?

- I think it's just the popular choice at the moment like avocado green was the hottest thing in the 1970s. I bought a Whirlpool Sateen. It has the look of stainless steel, but magnets will stick to it. There is no functional difference.

Send your message to us

prepainted steel coil from steel manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords