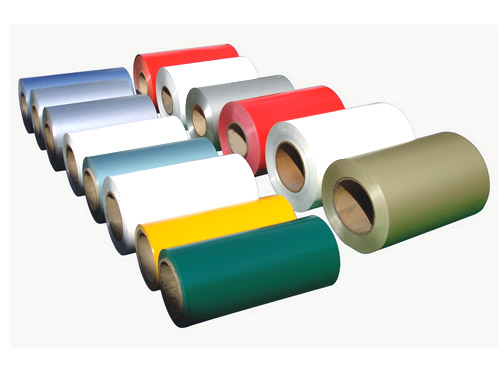

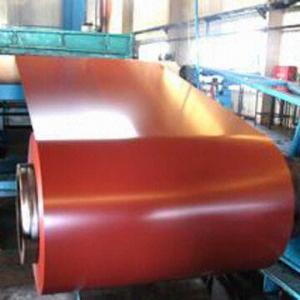

Prime Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

PPGI – White – Z100/Z120

709mm x 0.40mm x Coil

745mm x 0.35mm x Coil

745mm x 0.40mm x Coil

855mm x 0.50mm x Coil

1000mm x 0.40mm x Coil

1250mm x 0.50mm c Coil

PPGI – Dark Grey – Z100/Z120

1250mm x 0.50mm x Coil

shine surfaceVALIDITY: 3 WORKING DAYSPAYMENT: T/T WITH 30% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LISTSHIPMENT: 50 DAYS FOR CARGO READINESS AND 15 DAYS FOR CATCHING THE RIGHT VESSEL

- Q: What is the yield strength of steel coils?

- The yield strength of steel coils can vary depending on the specific grade and composition of the steel. However, on average, the yield strength of steel coils typically ranges from 250 to 350 megapascals (MPa).

- Q: I need the measurements of the height and hypotenuse of the first drop in the Steel Dragon 2000. I couldn't find it anywhere. It would be great if you could also show me the website where you got your answer. Thanks! =]*The hypotenuse is the length of the drop.*

- Steel Dragon 2000 is a roller coaster at Nagashima Spa Land Amusement Park in Mie Prefecture, Japan. Built by Morgan Manufacturing, this gigacoaster opened, appropriately, in 2000 - The Year of the Dragon in the Far East. It debuted only months after Millennium Force and surpassed the Cedar Point coaster as the world's tallest complete-circuit coaster. It also set a record for longest track length - 8133 feet, 2 inches (2479 m), which it currently holds. Coaster Facts * Steel Dragon 2000 is the tallest coaster to utilize a traditional chain lift. Because of the length of the lift hill, two chains are used - one for the bottom half and one for the top half. A single chain would have been excessively long and heavy, at least twice the weight of one of the trains. As a result, two trains can safely occupy the lift simultaneously. * The building of Steel Dragon 2000 required far more steel than other coasters for earthquake protection. This put the cost of the coaster at over $50,000,000. * On August 23, 2003, Steel Dragon 2000 was involved in an accident during a run in which one of its trains lost a wheel. The coaster did not operate during the 2004 and 2005 park seasons. It reopened September 3, 2006.

- Q: How are steel coils used in the production of agricultural equipment?

- Steel coils are used in the production of agricultural equipment as they are often shaped and formed into various components such as frames, chassis, and structural parts. These coils provide strength, durability, and stability to the equipment, making it capable of withstanding the demanding conditions and heavy workloads typically associated with agricultural tasks.

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils used in the transportation equipment industry can vary depending on the specific application and manufacturer. However, commonly used dimensions range from 0.015 inches to 0.625 inches in thickness and from 24 inches to 60 inches in width. The outer diameter of these coils typically falls within the range of 48 inches to 72 inches.

- Q: i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- You may want to experiment with different alloys to find which sound best on your guitar...but if it's acoustic, you should be using bronze wound strings.

- Q: I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Yes, carbon steels are magnetic. In fact, some stainless steel knives are magnetic as well. Some stainless steel alloys are naturally magnetic and some become magnetic when they are deformed by forging or rolling (check out a deep drawn SS sink and explore where it is magnetic and where it isn't). Depending on the details, some carbon steels can be made harder than the stainless steel typically used for knives (440 alloy) but the carbon steel knives are very much more likely to suffer corrosion. hope this helps

- Q: Specifically, for the main support beam found in a basement.

- Talk to the supplier of both the products on what is involved in installation, weight bearing over the span you are trying to go without supports,the size of beam, will it affect the height of the room below or will the floor have to go up and the cost how much are you prepared to spend, you will then get your answer

- Q: What are the advantages of using steel coils in various industries?

- There are several advantages of using steel coils in various industries. Firstly, steel coils offer exceptional strength and durability, making them suitable for heavy-duty applications. They can withstand extreme temperatures, pressure, and mechanical stress, ensuring reliable performance and longevity. Additionally, steel coils are highly resistant to corrosion, which is crucial in industries exposed to harsh environments or corrosive substances. Moreover, steel coils can be easily formed and shaped into different sizes and configurations, providing flexibility for various manufacturing processes. Lastly, steel is a sustainable material as it is recyclable, contributing to a greener and more environmentally friendly approach in industries.

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are processed for edge trimming or shearing by first uncoiling the coil and feeding it into a machine equipped with either rotary shears or slitting knives. These tools trim or shear the edges of the coil to remove any irregularities, ensuring a precise and uniform width. The trimmed edges are then inspected for quality and smoothness before the coil is recoiled for further processing or storage.

- Q: Hi can someone help me pleaseis there any available data for mechanical behaviour of recycled steel, i need to compare them with new steel.

- It is not clear from the question whether the recycled steel is used in its existing state or used as raw material for further fabrication. For the existing steel, you need to track down the original documents such as the ladle analysis and mill certificates certifying the material standards for which the steel was fabricated. Another alternative is take samples and conduct chemical and mechanical tests on the steel. Also the date of when the structure was built from which the steel is recycled may help indicate whether it is (American Society for Testing and Materials) Standard ASTM A7 or ASTM A36 or another type of steel. In most cases, the steel is used as raw material to make new steel. The mill will adjust the additives to produce steel with the required chemical and physical properties to meet the ASTM standards specified.

Send your message to us

Prime Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords