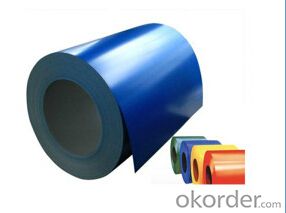

Prepainted Steel Coil for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:0.42*1180mm, RAL9010

Surface Treatment:Coated

Technique:Cold Rolled

Standard:ASTM, JIS, GB, DIN, BS

Steel Grade:ASTM A755m, En10169

Thickness 0.20~1.10mm:Coil Width 600~1250mm

Export Markets:Global

Additional Info.

Trademark:HZZN

Packing:STANDARD EXPORT PACKAGE, IN 20′ CONTAINER

Standard:0.42*1180mm, RAL9010

Origin:China

HS Code:7210701000

Production Capacity:10, 000 Tons/Year

Product Description

Description of Prepainted steel coils:

1) Standard: JIS G3312 CGCC & CGLCC, equivalent to ASTM A755M, EN10169

2) Grade: CGCC and CGLCC

3) Hardness of material: Both soft and full hard are available

4) Surface finish: With or without protect film covered

5) Thickness range: 0.14-1.20mm

6) Width range and General width: Width range 600-1250mm, general width: 914mm, 1000mm, 1220mm and 1250mm.

7) Shape: Both sheet and coil are available

8) Zinc coating: 60-275G/M2, both sides

9) Paint thickness: Top 5 um + (10-20) um modified polyester, any RAL color code. We use Beckers paint for producing

| Standard | JIS G3312 CGCC ASTM A755M EN10169 |

| Valid thickness | 0.20~1.20mm |

| Coil width | 600~1250mm |

| Coil ID | 508mm & 610mm |

| Coil weight | 3~5 tons |

| Zinc coating | 80~275 g/m2 |

| Thickness of top paint | 15~25 microns |

| Thickness of reverse paint | 5~7 microns |

| Color | any RAL code |

| Package | vertical, eye to sky & horizontal |

| MOQ | 25 tons |

- Q: Can you recycle steel? And if you wanted to buy some recycled steel, where would you get it?

- Hi, You bet ya.Right now its the big boom here in Maine.A lot of people are doing it ,its a good thing cause its helping clean up a lot of the junk around here. You could go to a scrap yard But I don't think they would seel much right now they are busier then ever just bringing in stuff. Anyways if you really got a lot let me know I can tell you everything you need to know and what to do with what you got. Mike

- Q: How are steel coils used in the manufacturing of pipes?

- Steel coils are used in the manufacturing of pipes as they provide the raw material needed for pipe production. The coils are uncoiled and then passed through a series of machines, where they are shaped, welded, and cut to the desired length and diameter. This process allows for efficient and precise pipe manufacturing, ensuring the strength and durability of the final product.

- Q: I'm planning to buy a pair of Doc Marten boots but I want some steel toed ones. I don't know if all of them are steel toed, or only some of them, or what?

- Steel Toe Doc Martens

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Magnets stick to some stainless but not all of it, so a magnet is not a reliable indicator.

- Q: What is the average lifespan of a steel coil?

- Several factors can influence the average lifespan of a steel coil. These factors encompass the quality and type of steel utilized, the conditions in which the coil is stored or used, and the maintenance and care it receives. Typically, a steel coil that is well-maintained can endure for approximately 10 to 30 years. Nevertheless, this is merely an approximation, and the actual lifespan can be either shorter or longer depending on the aforementioned factors. For example, if the coil is exposed to severe environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be diminished. Regular upkeep and proper storage can significantly prolong the longevity of a steel coil. This entails ensuring that the coil is stored in a dry and safeguarded environment, frequently inspecting and addressing any indications of corrosion or damage, and conducting routine cleaning and lubrication as necessary. Ultimately, the average lifespan of a steel coil is contingent upon various factors, and it is advisable to consult the manufacturer or industry experts for a more precise estimation based on specific circumstances and conditions.

- Q: What are the challenges in coil blanking for high-strength steel?

- Some challenges in coil blanking for high-strength steel include the increased hardness and strength of the material, which can lead to greater wear and tear on cutting tools. Additionally, high-strength steel may have less ductility, making it more prone to cracking or breaking during the blanking process. The higher tensile strength and spring-back characteristics of the steel also require precise control and adjustment of blanking parameters to ensure accurate and consistent part dimensions.

- Q: Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- The okorder /... Beware of eBay deals unless you know what you're buying. To start, you should get a 10-string single neck with 3 pedals and 4 levers. Some of the student models don't have as many levers and aren't capable of all the changes you need. Stay away from the ShoBud Maverick...you'll outgrow it in a couple of months. Often it makes more sense to buy a used professional model...you'll eventually need one, and they hold their value better than a student model. You'll also need a volume pedal, bar, thumb and finger picks. For now, your guitar amp will be ok. Playing the guitar: There are several tunings and lots of different combinations of levers, but the basic guitar is a 10 string E9 tuning. It's almost an open E but with a few extra notes. The pedals and levers raise and lower the pitch of selected strings. Chord changes are made by moving the bar and pressing pedals and levers. The volume pedal helps you swell and sustain notes. Steel has it's own unique tablature which reflects all these changes. If you have any other questions, feel free to email me or just join the PSG forum and ask there.

- Q: How are steel coils used in the production of telecommunications equipment?

- The production of telecommunications equipment commonly involves the use of steel coils, which offer structural support and durability. These coils are utilized to fabricate different components, including cabinets, racks, and enclosures. A significant application of steel coils in telecommunications equipment is seen in the manufacturing of cabinets. These cabinets serve as housing for the delicate electronic components and wiring utilized in telecommunications systems. Steel coils are typically shaped to form the cabinet structure, providing a robust and dependable enclosure for the equipment. The steel material also offers protection against external factors such as impacts, dust, and moisture, ensuring the longevity and integrity of the telecommunications equipment. Steel coils also find application in the production of racks for telecommunications equipment. These racks are designed to organize and provide accessibility to multiple devices, including servers, switches, and routers. The strength and rigidity of steel coils make them an ideal material for constructing these racks, ensuring they can bear the weight of multiple devices and withstand the constant handling and movement that occur in telecommunication environments. Moreover, steel coils are used to manufacture enclosures for telecommunications equipment. These enclosures act as protective casings, safeguarding sensitive electronic components from external influences such as electromagnetic interference and physical damage. Steel coils are often formed into specific shapes and sizes to create these enclosures, providing a sturdy barrier that shields the equipment from various external threats. In conclusion, steel coils play a crucial role in the production of telecommunications equipment by offering structural support, durability, and protection. They are employed in the creation of cabinets, racks, and enclosures, which ensure the proper functioning and longevity of the sensitive electronic components used in telecommunication systems.

- Q: Corten steel tends to overheat in hot environments? (for example copper heats up under the sun)

- Weathering steel, best-known under the trademark COR-TEN steel and sometimes written without the hyphen as Corten steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. Overheating ? It's not possible for a metal to get hotter than it's environment unless there is a source of radiation. The sun shining on a metal will heat up a bit, as will any material, but the amount is small and depends on the surface reflectivity. Define what you mean by overheating. .

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve inspecting the damage, assessing its severity, and determining if the coil is still safe to handle. If the damage is minor, it may be possible to repair or reinforce the coil. However, if the damage is extensive or compromises the structural integrity of the coil, it is recommended to contact a professional for further evaluation and potential disposal. Additionally, following proper safety protocols, such as wearing protective gear and using equipment suitable for handling heavy loads, is crucial when dealing with damaged steel coils.

Send your message to us

Prepainted Steel Coil for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords