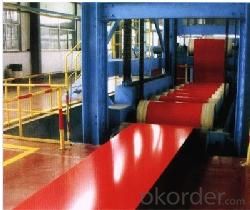

Prepainted steel coils, hot-dipped galvanized,

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB | Grade: | SGCC | Thickness: | 0.15-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Steel coil | |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Building material | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | accoding to type | Zinc coating: | 40-120g/m2 | Coil ID: | 508/610mm |

| Backside painting: | 7-10mic | Upside painting: | 13-25mic |

Packaging & Delivery

| Packaging Detail: | standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

| Delivery Detail: | 15-30days |

Specifications

ppgl steel coil

Thickness: 0.15-0.6mm

Width:600-1250mm

Color:all Ral color

Hardness: Soft to full hard

1.PPGL Steel information

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Galvanized steel coils, |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-15days after signing contract |

Price | FOB&CNF&CIF price |

Payment terms | TT or L/C |

Monthly supply | 30000MT per month |

Application: | workshop, storeroom, roofing,kiosk... |

- Q: How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they provide a durable and versatile material for creating structural components such as panels, cladding, and roofing. The coils are processed and shaped into the desired form, allowing for easy customization and installation. The strength and resistance of steel make it an ideal choice for facades, ensuring long-lasting and aesthetically pleasing buildings.

- Q: What are the different types of welding methods used for steel coils?

- There are several different types of welding methods used for steel coils, including gas metal arc welding (GMAW), flux-cored arc welding (FCAW), shielded metal arc welding (SMAW), and submerged arc welding (SAW). Each method has its own advantages and is used based on the specific requirements of the project.

- Q: How are steel coils used in the production of steel handles?

- Steel coils are used in the production of steel handles by being processed and shaped into the desired handle design. The coils are uncoiled and fed into a machine where they are cut, bent, and formed to create the handle shape. The coils provide the raw material needed for the manufacturing process, ensuring the handles are strong, durable, and able to withstand the required usage.

- Q: How do steel coils contribute to energy efficiency in transportation?

- There are several ways in which steel coils help improve energy efficiency in transportation. To begin with, steel coils are lightweight and have a high strength-to-weight ratio. This means that they require less steel material to carry the same load compared to other materials like wood or concrete. As a result, the overall weight of the transport vehicle is reduced, leading to lower fuel consumption and emissions. Furthermore, steel coils are extremely durable and can withstand harsh transportation conditions. They are highly resistant to corrosion, impact, and fatigue, ensuring a longer lifespan for the transport vehicle. This durability reduces the need for frequent repairs or replacements, resulting in reduced energy consumption and material waste. Moreover, steel coils are easily handled and transported. Due to their compact and standardized size, they can be effortlessly loaded and unloaded from trucks, trains, or ships. This efficiency in handling reduces the time and energy required for loading and unloading operations, ultimately increasing overall transportation efficiency. Additionally, steel coils can be efficiently stacked and stored, maximizing the utilization of available space in transport vehicles. This reduces the number of trips needed to transport the same amount of goods, resulting in less energy consumption and lower transportation costs. Lastly, steel is a highly recyclable material. At the end of their life cycle, steel coils can be easily recycled and used to produce new steel products. This reduces the demand for raw materials and the energy required for manufacturing new products, thereby contributing to overall energy efficiency in transportation. In conclusion, steel coils play a crucial role in enhancing energy efficiency in transportation. Their lightweight, durable, easy-to-handle, and recyclable nature leads to decreased fuel consumption, lower emissions, reduced maintenance needs, efficient use of space, and minimized material waste. All of these factors contribute to a more sustainable and energy-efficient transportation system.

- Q: How are steel coils used in the production of electrical devices?

- The production of electrical devices heavily relies on steel coils. These coils, typically made from high-quality steel, are precisely wound into a circular shape. They have a crucial function in various electrical devices, including transformers, motors, generators, and inductors. Transformers, for instance, heavily rely on steel coils. These devices are essential for adjusting voltage levels in electrical circuits. They consist of two separate coils, the primary and secondary coils, which are wound around a magnetic core. The steel coil plays a vital role in providing stability and support to the windings, ensuring proper alignment and preventing any deformation. Moreover, the high magnetic permeability of steel helps enhance the efficiency of energy transfer between the coils. In motors and generators, steel coils are utilized to create magnetic fields that either generate mechanical energy or convert it into electrical energy. These coils are wound around an armature or rotor, which rotates within a magnetic field created by a stator. As the current flows through the coils, a magnetic field is produced, resulting in the rotation of the armature or the generation of electrical power. Steel coils are also used in inductors, another type of electrical device. Inductors consist of a coil of wire wound around a core material, often made of steel. Steel coils in inductors help increase the inductance, which measures the device's ability to store energy in a magnetic field. By storing energy in this manner, inductors can regulate currents, filter out noise, and provide stability to electrical circuits. All in all, steel coils are indispensable in the production of electrical devices. They provide stability, support, and enhance the necessary magnetic properties for efficient functioning. Without steel coils, the performance and reliability of electrical devices like transformers, motors, generators, and inductors would be greatly compromised.

- Q: I have a necklace that has a pendent made out of stainless steel. The pendent is connected by a cord, not chain, that I can take on and off; so, I leave it on all the time. It has gotten pretty tarnished because of that.

- stainless steel polish and steel wool(not being a smart azz either).

- Q: How are steel coils cut to size?

- Steel coils are cut to size using a process called slitting, where the coil is fed through a series of rotating circular blades that make multiple cuts along its length. The blades are spaced at specific distances to achieve the desired width, and the cut strips are then rewound into separate coils.

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless Steel comes in many different grades, a prime example is to see if a magnet sticks to it if so it has a high iron content as the grade of the stainless increases its magnetic ,iron properties decrease have you ever left a stainless knife, fork, spoon in a kitchen sink for a few days it will show evidence of rusting most jewelery is low grade stainless as it does not need to to be suitable for medical grade or marine grade quality under normal conditions wearing your stainless steel watch will not make it rust however if you were to leave that watch in contact with another metal and they are wet then yes it will rust as it will create a chemical reaction.

- Q: I'm in the process of buying a new car, and wondering if there are more benefits from Aluminum tire rims over Steel. Aluminum wheels cost more, but you'd think that steel would last longer. Are Aluminum wheels just for looks?

- Steel rusts....The nicer wheels are aluminum alloys. Go with the aluminum

- Q: which cost more: ALLOY, GUNMENTAL OR STAINLESS STEEL. GIVE ME AN IDEA OF THE COST OF EACH.

- Titanium alloy is. Its the hardest metal in the world and takes about 6 months to produce. I sell titanium juliets for 350.

Send your message to us

Prepainted steel coils, hot-dipped galvanized,

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords