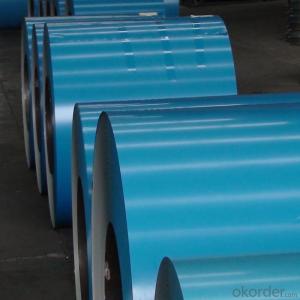

Prepainted Rolled Steel Coil for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description Info.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:JIS

Color:All Ral Color Are Available

Zinc Coating:30-120G/M2

Width:914-1250mm

Thickness:0.18-0.6mm

Export Markets:Global

Additional Info.

Trademark:VST

Packing:Standard Export Package

Origin:China

Production Capacity:10000t/Month

Product Description

Main Feature:

1, Pre-painted Steel Coil Can be used in building material field, galvanized wire steel tape and mainly other fields.

2, All color can be customized

3, Good quality with competitive price

| Performance testing of color coated steel coil | ||

| Item | Method | Consequence |

| Tensile Test | Tic-Tac-9mm 5mm cross cupping | No damage |

| Bending Test | T≤ 3 | No damage |

| Boiling Test | 100° Cboiling 1 hour | No damage |

| Water Resistance | 1000hours immersion in 40° C(edge) | No damage |

| Moisture Resistance | 50° C90%100hours(edge) | No damage |

| Fire Resistance | Samples were placed in incubators, remove greenhouse cooling, and then test the adhesion | Long-term Environment in 100° C |

| Fire Extinction | Liquefied petroleum gas or natural gas burner | Immediately turn off |

| Drug Resistance | 10%hydrochloric acid, saturated calcium, 10%H2SO4, 10%NAOH, gasoline, ethanol | No color and trace change |

| Salt spray test | 5%Nacl, 35± 2° C, 500hours | No damage |

| Coating performance test standard | ||

| Test item | Positive standard | Back standard |

| Dry film thickness(um) | 14-16 | 7-9 |

| Glass(60degree) | High 70± 5, medium40± 5, low30± 5 | 30± 5degree |

| T bending | 3 | 3 |

| Impact strength | 6.3 | 5.8 |

| Pencil hardness(H) | H | H |

| MEK(Per) | > 100 | > 100 |

| Cross cut | 0 class | 0 class |

| Acid resistance | 50%H2SO4 immersion in300hrs, no color, wrinkling, fading, change | |

| Alkali resistance | 50%H2SO4 immersion in300hrs, no color, wrinkling, fading, change | |

| Aging-resistance | 1 st class loss of color and glass | |

| Salt spray | 500 | |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: What are the industries that consume the most steel?

- Costuuction and auto are most likely the top two.

- Q: What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- High Carbon Spring Steel

- Q: What are the main applications of steel coils?

- The main applications of steel coils include manufacturing of automobiles, construction materials, appliances, furniture, and packaging materials. They are also used in various industries such as oil and gas, aerospace, and shipbuilding.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- you can search for some web which sells steel pipe and other relative products to know more details.

- Q: How do steel coils contribute to the manufacturing of oil and gas equipment?

- Steel coils are an essential component in the manufacturing of oil and gas equipment. These coils are typically made from high-quality steel that is durable, strong, and resistant to corrosion, making them ideal for withstanding the harsh environments and conditions encountered in the oil and gas industry. One of the primary applications of steel coils in oil and gas equipment manufacturing is in the fabrication of pressure vessels. Pressure vessels are crucial components used for storing and transporting various fluids and gases under high pressure. Steel coils are used to form the cylindrical shells of these vessels, providing the necessary strength and structural integrity to withstand the internal pressure. Steel coils are also utilized in the construction of oil and gas pipelines. These pipelines are responsible for transporting vast quantities of oil and gas over long distances. Steel coils are used to manufacture the pipes that make up these pipelines, providing the necessary strength, durability, and resistance to corrosion. The coils are rolled and welded to form seamless or welded pipes, which are then coated or lined to prevent corrosion and enhance their longevity. Furthermore, steel coils are instrumental in the production of drilling equipment used in the extraction of oil and gas. This equipment includes drill bits, casings, and wellheads, which are crucial for drilling and completing wells. The coils are used to fabricate these components, ensuring they can withstand the demanding conditions encountered during drilling operations. In addition to their structural applications, steel coils are also used in the manufacturing of ancillary equipment such as tanks, storage containers, and heat exchangers. These components play a vital role in the processing, storage, and distribution of oil and gas. Steel coils provide the required strength and durability to handle the harsh conditions and corrosive substances encountered in these processes. Overall, steel coils are indispensable in the manufacturing of oil and gas equipment. Their strength, durability, and resistance to corrosion make them a preferred choice in the industry. By contributing to the fabrication of pressure vessels, pipelines, drilling equipment, and ancillary components, steel coils ensure the safe and efficient extraction, processing, and transportation of oil and gas.

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are typically processed for edge trimming or shearing by using specialized machinery such as slitters or shears. These machines are designed to cut the excess edges of the coil, ensuring uniform and precise dimensions. The coils are fed through the machine, where the excess material is removed, leaving clean and straight edges. This process helps to enhance the quality and appearance of the steel coils, making them ready for further manufacturing or fabrication.

- Q: What brand steel tapes are of good quality?

- Durable durable depends on your personal use frequency, the high frequency nature is easy to wear, resulting in scale. If you like fuzzy units if buying tape need verification it is best to buy the Great Wall Seiko goods, because the time to measure the number of verification inspection of steel tape, basically qualified rate of the Great Wall Seiko steel tape can reach one hundred percent.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- actually stain less steel is mainlly three first one is austenitic, 2nd one is ferritic, and 3rd is martensitic. These three types of steels are identified by their microstructure or predominant crystal phase. Austenitic. Austenitic steels have austenite as their primary phase (face centered cubic crystal). These are alloys containing chromium and nickel (sometimes manganese and nitrogen), structured around the Type 302 composition of iron, 18% chromium, and 8% nickel. Austenitic steels are not magnetic and not hardenable by heat treatment. The most familiar stainless steel is 304 containing 18-20% chromium and 8-10% nickel. Ferritic. Ferritic steels have ferrite (body centered cubic crystal) as their main phase. These steels contain iron and chromium. Ferritic steel is somewhat magnetic, less ductile than austenitic steel, and is not hardenable by heat treatment. Martensitic. Martensitic steels have orthorhombic martensite as their main phase. Martensitic steels are low carbon steels. They are magnetic, and may be tempered and hardened. Martensite gives steel great hardness, but it also reduces its toughness and makes it brittle. If you ran around the house with a magnet, checking on the items you know are stainless steel, you would probably find that cookware and flatware are not magnetic, but cutlery might be slightly magnetic.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through a series of visual and mechanical tests. Firstly, the external appearance of the coil is examined to ensure it is free from any visible defects such as dents, scratches, or rust. This is important as it ensures the coil's overall integrity and prevents potential issues during further processing. Next, the thickness of the coil is measured at various points using non-destructive testing techniques like ultrasonic or magnetic particle inspection. This helps identify any variations in thickness, which could affect the coil's overall quality and performance. Additionally, the width of the coil is measured using precision instruments to check for any deviations from the required specifications. This ensures that the coil is within the desired width range, which is crucial for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. This is typically done using weighing scales or load cells, ensuring that the weight is consistent and meets the required standards. In terms of internal inspection, steel coils are sometimes subjected to eddy current testing, a non-destructive method that detects surface and near-surface defects. This technique uses electromagnetic induction to identify any irregularities in the metal, enabling the identification of defects such as cracks, voids, or inclusions. Overall, a combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures that steel coils are thoroughly inspected for uniformity. These rigorous inspection processes help guarantee the quality and reliability of the coils, allowing them to meet the industry standards and customer requirements.

Send your message to us

Prepainted Rolled Steel Coil for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords