prepainted rolled Steel coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

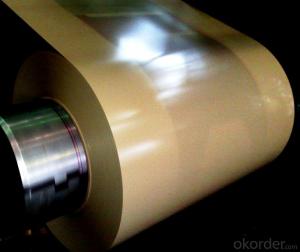

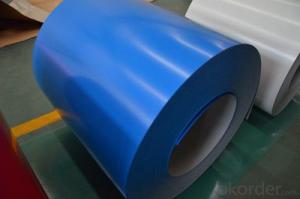

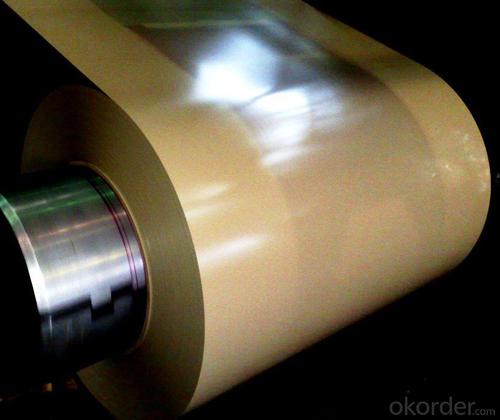

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How long can steel coils be stored before they need to be used?

- Steel coils can typically be stored for an extended period of time, ranging from a few months to several years, depending on various factors such as the coating, storage conditions, and the type of steel. However, it is generally recommended to use or sell steel coils within a year or two to ensure their optimal quality and performance.

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- Stainless steel is a fascinating metal to weld. Welding stainless can be difficult if you don't know what you are doing. It reacts to excessive heat by warping and distorting once it cools. Everything shows up in stainless. If you weld with too much heat you can see it by the heat marks left in the metal along with any distortion. It also scratches very easily so you must take care when welding on a metal table. Stainless steels can be welded using several different procedures such as shielded metal arc welding, gas tungsten arc welding, and gas metal arc welding but stainless steel welding wires have been developed for welding stainless steels.

- Q: How are steel coils processed for edge trimming or slitting during processing?

- Steel coils are processed for edge trimming or slitting during processing by utilizing specialized machinery. The coils are unwound and fed into the machine, where the edges are trimmed off to achieve the desired width. For slitting, the coil is passed through multiple sets of circular blades that cut it into narrower strips. This process ensures precise dimensions and smooth edges, making the steel coils ready for further applications.

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Steel okorder /

- Q: How are steel coils used in the production of industrial tanks?

- Steel coils are used in the production of industrial tanks as they are rolled and formed into the desired shape to create the tank's structure. The coils provide the necessary strength and durability required to withstand the pressure and weight of the tank's contents.

- Q: gigantic navy ships made of steel float, why??

- They okorder /... Or use the search bar*. (The question has been answered a thousand and one times). If you do then you will read many answers that push the popular myth that they displace more water than they weigh (as if some unseen 'finger of god' is supplying a mystery force in addition to the vessel's weight). Such 'explanations' cannot be supported by either calculation or experiment and are wishy-washy drively nonsense. So beware of Archimedes' Trolls on this one!

- Q: I wanted to know what is steel fabricating?

- Steel Fabricating/or Steel Fabricators is just a fancy way of saying that they sell steel products and a variety of related services. Thomas steel products has a wide range of steel products and services, from Windsor Republic Door Dist, Tie Wire, Steel Doors Frames, Snap Ties, S Parker Hardware Distributor, Reinforcing Steel Detail Drawings Avail, Rebar Fabrication, o_O.

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel bands or straps. They are then placed on wooden pallets or in steel cradles to ensure stability during transportation. Additionally, protective packaging materials such as plastic or cardboard may be used to prevent damage from moisture, dust, or other external factors.

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

- Q: Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- Steel okorder

Send your message to us

prepainted rolled Steel coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords