Prepainted Rolled Coil for Construction Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

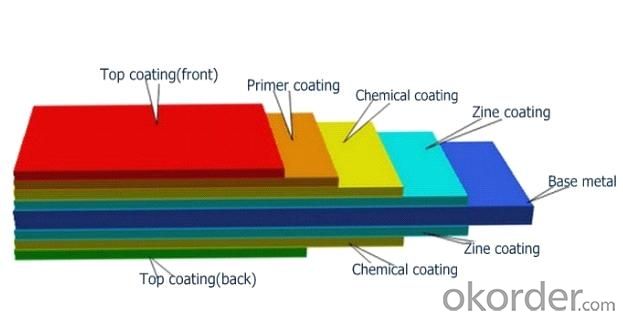

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Actually okorder /

- Q: What are the different types of steel coil storage systems used during processing?

- There are several types of steel coil storage systems used during processing, including coil racks, coil cradles, coil saddles, coil cars, coil turnstiles, and coil transfer cars.

- Q: Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep drawing is a metal forming process in which a sheet or coil of material, such as steel, is stretched and pulled into a die to create a deep, hollow shape. Steel coils are often used in industries such as automotive, appliance, and manufacturing, where deep-drawn components are required for various applications.

- Q: What are the common surface defects in steel coils?

- Steel coils commonly have surface defects, including scratches, pits, indentations, stains, and rust spots. Scratches may occur due to mishandling or processing, and their depth and length can vary. Pits are small depressions caused by impurities in the steel or during manufacturing. Indentations are similar but larger and more noticeable. Stains can result from chemicals, water, or other contaminants coming into contact with the steel. Rust spots form when the steel is exposed to moisture or corrosive elements, leading to iron oxide formation. These defects can impact the appearance, quality, and performance of the steel, necessitating their resolution to ensure the intended use of the coils.

- Q: What is the process of galvanizing steel coils?

- The process of galvanizing steel coils involves immersing them in a bath of molten zinc to create a protective coating. The coils are first cleaned and then passed through a series of chemical baths to prepare the surface for galvanization. Afterward, they are dipped into the molten zinc, which bonds to the steel to form a corrosion-resistant layer. Once coated, the coils are cooled, inspected, and prepared for shipment or further processing.

- Q: How are steel coils processed before being used in manufacturing?

- Before steel coils are used in manufacturing, they undergo a series of processing steps. Initially, the steel coil is uncoiled from a large spool, a process that is typically carried out using a machine known as a decoiler. Once the coil is uncoiled, it is carefully inspected for any defects or damages. Following inspection, the steel coil is subjected to a process called leveling. This involves passing the coil through a set of rollers to eliminate any unevenness or waviness in the steel. By doing so, the leveling process guarantees that the coil has a uniform thickness and a flat surface, which is crucial for subsequent processing. The subsequent step involves thoroughly cleaning the steel coil to eliminate any impurities it may have, such as rust, oil, or dirt. Typically, this is accomplished by running the coil through a cleaning line, where it is treated with chemicals and water sprays. Through this cleaning process, the surface of the coil is thoroughly cleansed of any contaminants that could potentially compromise the quality of the final product. Once the cleaning process is complete, the steel coil may undergo additional processes tailored to the specific requirements of the manufacturing process. For instance, the coil may undergo annealing to enhance its ductility and reduce its hardness. Annealing entails heating the coil to a specific temperature and gradually cooling it. This process serves to alleviate internal stresses and enhance the mechanical properties of the steel. Upon completion of all necessary processing steps, the steel coil is now ready to be utilized in the manufacturing process. It can be further processed into various forms and shapes, such as sheets, plates, or strips, depending on the specific requirements of the manufacturing process. These processed steel coils find application in a wide array of industries, including automotive, construction, appliances, and machinery.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- This Site Might Help You. RE: Why can aluminum and steel casings not be used for reloading? I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Q: How are steel coils used in the production of automotive chassis?

- Steel coils are used in the production of automotive chassis as they are cut and shaped into various components, such as frame rails and crossmembers, which form the structural foundation of the vehicle. The high strength and durability of steel make it an ideal material for chassis construction, providing stability and safety to the overall vehicle structure.

- Q: So I want to get my 3+ wood shafted with a dynamic gold shaft because i need a stiffer shaft but dont want to spend much on it.I've never swung a steel shafted wood, but I hear that it is more consistent that graphite....Plus, since the cost of steel is only $15 compared to the $65 graphite, not to mention installation charges.So yeah...... How good is steel for fairway woods?BTW, my swing speed is about 95 but i can amp it up to 110 (with control, that is)

- If your club has a graphite shaft in it and you want to switch to steel an option is to get a dynamic gold lite shaft. The other option is to make sure you trim the shaft to the 42 length with the gold shaft to lighten up the swing weight. You can get away with about 42 3/4 with the lite shaft. I have found steel to be very consistent in my fairway woods and don't think I'll ever go back to graphite. I have mine cut to 42 1/2 for the 3 wood and 41 1/2 for the 5 wood with Dynamic gold s300 and they're fine.

Send your message to us

Prepainted Rolled Coil for Construction Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords