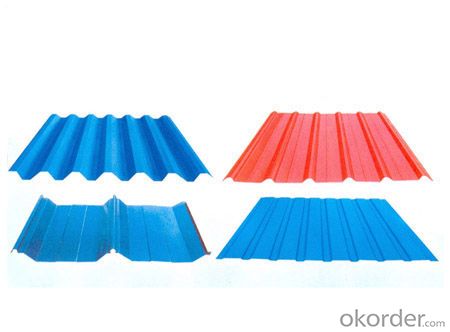

Prepainted galvanized corrugated sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGHC,DX51D.. | Thickness: | 0.14-3.0mm |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | Model Number: | 600-1250mm | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | coated ,galvanized |

| Application: | building ,house,construction | Special Use: | Wear Resistant Steel | Width: | 600-1250mm |

| Length: | Any length | sample: | free available | quality: | first class |

| stock: | 5766tons | company type: | manufacturer & exporter | product name: | prepainted galvanized corrugated steel sheet |

Packaging & Delivery

| Packaging Detail: | 1.packed in bundles 2.waterproof packing 3.packed by steel strip 4.as per to clients |

| Delivery Detail: | within 5-20 days after receipt deposit or L/C at sight. |

Specifications

prepainted galvanized corrugated sheel sheet

1.Thickness:0.14-3.0mm

2.Width:600-1250mm

3.In stock

4.Fast delivery

prepainted galvanized corrugated steel sheet | |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | DX51D SGCC, DC51D,SPCC |

Thickness | 0.14-3.0mm |

Width | 600-1250mm(1250,1220,1000, 980mm, 900mm ,840mm, 820mm, 750mm) |

Coating | PE ,PVDF, HDP ,galvanized(30-300g), galvalume (AZ80) |

Color | According to RAL card |

Length | cut as client’s request, but considering the transportation , its better to cut less than 5.8 meter (for 20’ft container) , or 11.8 meter (for 40’ft container). |

Remarks | 1.Payment terms:T/T, L/C 2.Trade terms:FOB, CNF, CIF 3.Port:Shanghai 4.Supply ability:5000Tons/month 5.Delivery time: within 15-20 days after receiving the deposit. |

- Q: Are steel sheets suitable for exterior cladding?

- Yes, steel sheets are suitable for exterior cladding. They are durable, weather-resistant, and provide a sleek and modern appearance to buildings. Additionally, steel sheets offer great strength and can withstand harsh environmental conditions, making them a reliable choice for exterior applications.

- Q: What is the difference between a black and pickled steel sheet?

- A black steel sheet refers to a plain carbon steel sheet that has not undergone any additional surface treatment. It has a characteristic dark appearance due to the presence of an iron oxide scale on its surface. On the other hand, a pickled steel sheet has undergone a surface treatment process called pickling, which involves removing the oxide scale using an acid solution. This treatment results in a clean and smooth surface, making it more suitable for further processing or application.

- Q: What are the different shapes available for steel sheets?

- There are several different shapes available for steel sheets, depending on the specific requirements and applications. Some of the commonly used shapes include: 1. Flat sheets: These are the most basic and versatile shape of steel sheets. They have a flat surface and are available in various sizes and thicknesses. Flat sheets are commonly used in construction, automotive, and manufacturing industries. 2. Coils: Steel sheets can also be available in coils, which are continuous lengths of sheet metal wound into a roll. Coils are often used for large-scale production processes, such as in the manufacturing of appliances, automobiles, and HVAC systems. 3. Perforated sheets: These sheets have evenly spaced holes or perforations throughout their surface. Perforated sheets are used in applications where ventilation, filtration, or aesthetic appeal is required, such as in architectural designs, signage, and industrial machinery. 4. Corrugated sheets: These sheets have a series of parallel ridges and grooves, which provide strength and rigidity. Corrugated sheets are commonly used for roofing and siding applications, as they offer excellent durability and weather resistance. 5. Expanded metal sheets: These sheets are manufactured by cutting and stretching a flat sheet, creating a pattern of diamond-shaped openings. Expanded metal sheets are used in applications that require ventilation, security, or filtration, such as fences, walkways, and machine guards. 6. Diamond plate sheets: Also known as tread plate or checker plate, these sheets have a pattern of raised diamonds or lines on their surface. Diamond plate sheets are commonly used for flooring, stairs, ramps, and truck bed liners, as they provide traction and slip resistance. These are just a few examples of the different shapes available for steel sheets. The choice of shape depends on the specific requirements of the project, including strength, durability, aesthetics, and functionality.

- Q: How do steel sheets perform in seismic zones?

- Steel sheets perform well in seismic zones due to their inherent strength and ductility. The flexibility and high tensile strength of steel allow it to absorb and dissipate the energy generated during seismic events such as earthquakes. This helps to minimize damage and maintain the structural integrity of buildings and other structures. Steel sheets are commonly used in seismic design and construction because they offer several advantages. Firstly, steel is a lightweight material, which reduces the overall weight of the structure and allows for more efficient seismic design. Additionally, steel sheets can be easily fabricated and assembled, making the construction process faster and more cost-effective. In seismic zones, steel sheets are often used in the form of shear walls or bracing systems. These elements are strategically placed throughout the building to provide lateral stability and resist the forces generated by earthquakes. Steel sheets can also be used as a cladding material, providing an additional layer of protection against seismic forces. Moreover, steel has excellent fire resistance properties, which further enhances its performance in seismic zones. In the event of a fire, steel sheets retain their structural integrity for a longer duration compared to other materials, ensuring the safety of occupants and reducing the risk of collapse. Overall, steel sheets are a reliable and effective choice for construction in seismic zones. Their strength, ductility, lightweight nature, ease of fabrication, and fire resistance make them an ideal material for ensuring the safety and stability of structures during seismic events.

- Q: Can steel sheets be used in corrosive environments like saltwater?

- Yes, steel sheets can be used in corrosive environments like saltwater. However, the type of steel and the level of corrosion resistance it offers will determine its suitability for such conditions. Stainless steel, for example, is highly resistant to corrosion and is often used in marine and saltwater environments. It contains chromium, which forms a protective layer on the surface of the steel, preventing it from reacting with the saltwater. Other types of steel, such as carbon steel, may also be used in saltwater environments, but they require additional protective coatings or treatments to prevent corrosion. Regular maintenance and proper care are essential to ensure the longevity of steel sheets in corrosive environments like saltwater.

- Q: What is the difference between a corrugated and flat steel sheet?

- The main difference between a corrugated and flat steel sheet lies in their structural design. A corrugated steel sheet is characterized by its wavy pattern formed by parallel ridges and grooves. This design provides added strength and rigidity to the sheet, making it suitable for applications that require enhanced load-bearing capabilities. Additionally, the ridges in a corrugated sheet help to increase its resistance to bending and impact, making it a popular choice for roofing and siding applications. On the other hand, a flat steel sheet lacks any ridges or grooves and is characterized by its smooth, flat surface. This design makes it more flexible and easier to fabricate into various shapes and sizes. Flat steel sheets are commonly used in applications that require a smooth and even surface, such as automotive body panels, appliances, and fabrication projects. In terms of visual appearance, corrugated steel sheets have a more distinctive and textured look due to their wavy pattern, while flat steel sheets have a sleek and uniform appearance. Overall, the choice between a corrugated and flat steel sheet depends on the specific application and desired characteristics. If enhanced strength and load-bearing capabilities are required, a corrugated sheet would be preferred. However, if versatility and ease of fabrication are important, a flat steel sheet would be the more suitable option.

- Q: What is the typical coefficient of thermal expansion of a steel sheet?

- The typical coefficient of thermal expansion of a steel sheet is around 10-12 parts per million per degree Celsius (ppm/°C). This means that for every degree Celsius increase in temperature, the steel sheet will expand by 10-12 ppm in all directions. However, it's important to note that the coefficient of thermal expansion can vary depending on the specific type and composition of the steel. Different types of steel alloys may have slightly different coefficients, but the range of 10-12 ppm/°C is a common average.

- Q: What is the difference between a pre-annealed and full hard steel sheet?

- A pre-annealed steel sheet refers to a steel sheet that has undergone the annealing process, which involves heating the steel to a specific temperature and then cooling it slowly. This process helps to relieve internal stresses in the steel and improve its ductility and workability. As a result, pre-annealed steel sheets possess higher levels of formability and are easier to shape and manipulate compared to their non-annealed counterparts. On the other hand, a full hard steel sheet has not undergone the annealing process and retains its original hardness and strength. Full hard steel sheets are typically used in applications that require high strength, durability, and resistance to deformation. These sheets are more rigid and less ductile, making them suitable for applications where shape retention and stiffness are critical, such as in automotive components or structural supports. In summary, the main difference between pre-annealed and full hard steel sheets lies in their formability and strength characteristics. Pre-annealed steel sheets are more malleable and easier to shape, while full hard steel sheets offer higher strength and rigidity. The choice between the two depends on the specific requirements of the application and the desired balance between formability and strength.

- Q: How do steel sheets perform in vibration and noise reduction?

- Steel sheets are effective in vibration and noise reduction due to their dense and rigid nature, which helps dampen vibrations and minimize noise transmission.

- Q: What are the different coating options available for steel sheets?

- There are several coating options available for steel sheets, each offering unique benefits and protection against various environmental factors. Some of the most common coating options include: 1. Galvanized Coating: This is the most widely used coating for steel sheets. It involves applying a layer of zinc to the surface, which acts as a sacrificial anode and prevents corrosion. Galvanized coating provides excellent corrosion resistance and is suitable for both indoor and outdoor applications. 2. Galvannealed Coating: This coating is similar to galvanized coating but is further heat-treated to form a zinc-iron alloy layer on the surface. Galvannealed coating offers improved paint adhesion and weldability, making it suitable for applications that require painting or additional fabrication processes. 3. Electroplated Coating: This process involves immersing the steel sheet in a solution containing metal ions and applying an electric current to deposit a thin layer of metal onto the surface. Common electroplated coatings include zinc, nickel, and chromium. Electroplated coatings provide enhanced corrosion resistance and can also improve aesthetics. 4. Organic Coating: Also known as painted or coated steel sheets, this option involves applying a layer of organic material such as paint, powder coating, or plastic film to the steel surface. Organic coatings provide protection against corrosion, UV radiation, and abrasion. They also offer a wide range of colors and finishes, making them suitable for architectural and decorative applications. 5. Tin Coating: Tin-plated steel sheets have a thin layer of tin applied to the surface through an electroplating process. Tin coating provides excellent solderability, corrosion resistance, and food-grade suitability. It is commonly used in the production of food cans and other packaging materials. 6. Aluminized Coating: This coating involves applying a layer of aluminum to the steel surface through a hot-dipping process. Aluminized coating provides excellent heat reflectivity, corrosion resistance, and thermal conductivity. It is often used in applications that require heat resistance, such as exhaust systems and heat exchangers. These are just a few of the many coating options available for steel sheets. The choice of coating depends on factors such as the intended use, environmental conditions, and desired properties of the steel sheet. It is essential to consider these factors and consult with coating experts to determine the most suitable option for specific applications.

Send your message to us

Prepainted galvanized corrugated sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords