All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

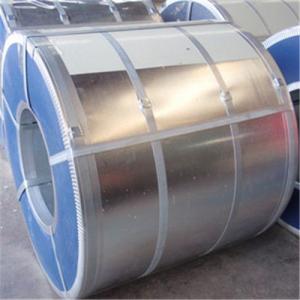

- - Cold Rolled Steel

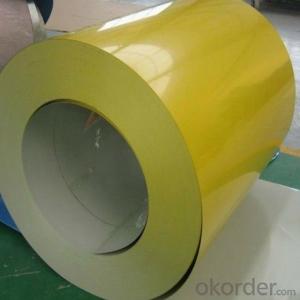

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are implemented to maintain coil flatness during storage and transport?

To maintain coil flatness during storage and transport, various measures are implemented. One common measure is the use of sturdy and well-designed coil packaging materials, such as steel straps or bands, to securely hold the coils in place and prevent any movement that could cause deformation. Additionally, coil manufacturers often apply tension to the coils before packaging, which helps to maintain their flatness. Proper stacking and storage techniques are also crucial, ensuring that the coils are stored in a horizontal position and not subjected to excessive weight or pressure. Finally, monitoring and controlling the storage environment, such as humidity and temperature levels, can further aid in preserving coil flatness.

How are steel coils inspected for surface defects and irregularities in the automotive industry?

Steel coils in the automotive industry are inspected for surface defects and irregularities using various methods such as visual inspection, magnetic particle inspection, and ultrasonic testing. Visual inspection involves a thorough visual examination of the coil's surface to identify any visible defects like scratches, dents, or corrosion. Magnetic particle inspection is a non-destructive testing method that uses magnetic fields and iron particles to detect surface cracks or defects that may not be visible to the naked eye. Ultrasonic testing, on the other hand, involves the use of high-frequency sound waves to detect internal or subsurface defects by analyzing the reflected waves. These inspection techniques ensure that steel coils used in the automotive industry meet the required quality standards and are free from any surface defects or irregularities.

How are steel coils tested for their ability to withstand extreme temperatures?

Steel coils are tested for their ability to withstand extreme temperatures through a process called thermal cycling. This involves subjecting the coils to alternating cycles of high and low temperatures to simulate real-world conditions. The coils are heated and cooled repeatedly to evaluate their performance and ensure they can withstand the extreme temperature variations without any structural or functional damage.

Wholesale Steel Coils from supplier in Angola

With a wide range of steel coil products to offer, we can cater to various industries and applications in Angola. Whether you need hot-rolled coils, cold-rolled coils, galvanized coils, or any other type of steel coils, we have the capabilities to meet your requirements.

Our team of experts is highly knowledgeable about the steel industry and understands the specific needs and challenges faced by clients in Angola. We can provide valuable insights and advice to help you make informed decisions and optimize your procurement process.

In addition to supplying steel coils, we also offer a range of services to support our clients' projects. This includes assistance with product selection, technical support, and after-sales service. We strive to provide a seamless experience from the initial sales and quotation process to the delivery of the products.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This allows us to source high-quality steel coils at competitive prices, ensuring cost-effectiveness for our clients in Angola.

Whether you are involved in construction, manufacturing, or any other industry requiring steel coils, we are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and find out how we can support your projects in Angola.

Our team of experts is highly knowledgeable about the steel industry and understands the specific needs and challenges faced by clients in Angola. We can provide valuable insights and advice to help you make informed decisions and optimize your procurement process.

In addition to supplying steel coils, we also offer a range of services to support our clients' projects. This includes assistance with product selection, technical support, and after-sales service. We strive to provide a seamless experience from the initial sales and quotation process to the delivery of the products.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This allows us to source high-quality steel coils at competitive prices, ensuring cost-effectiveness for our clients in Angola.

Whether you are involved in construction, manufacturing, or any other industry requiring steel coils, we are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and find out how we can support your projects in Angola.